Anti-static and flame retardant cotton-polyester fabrics and processing method thereof

A technology of flame retardant fabrics and processing methods, applied in the directions of plant fibers, textiles and papermaking, fiber types, etc., can solve the problems of lack of flame retardant properties, easy to play a scaffold effect, etc., to achieve quality assurance, low cost, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

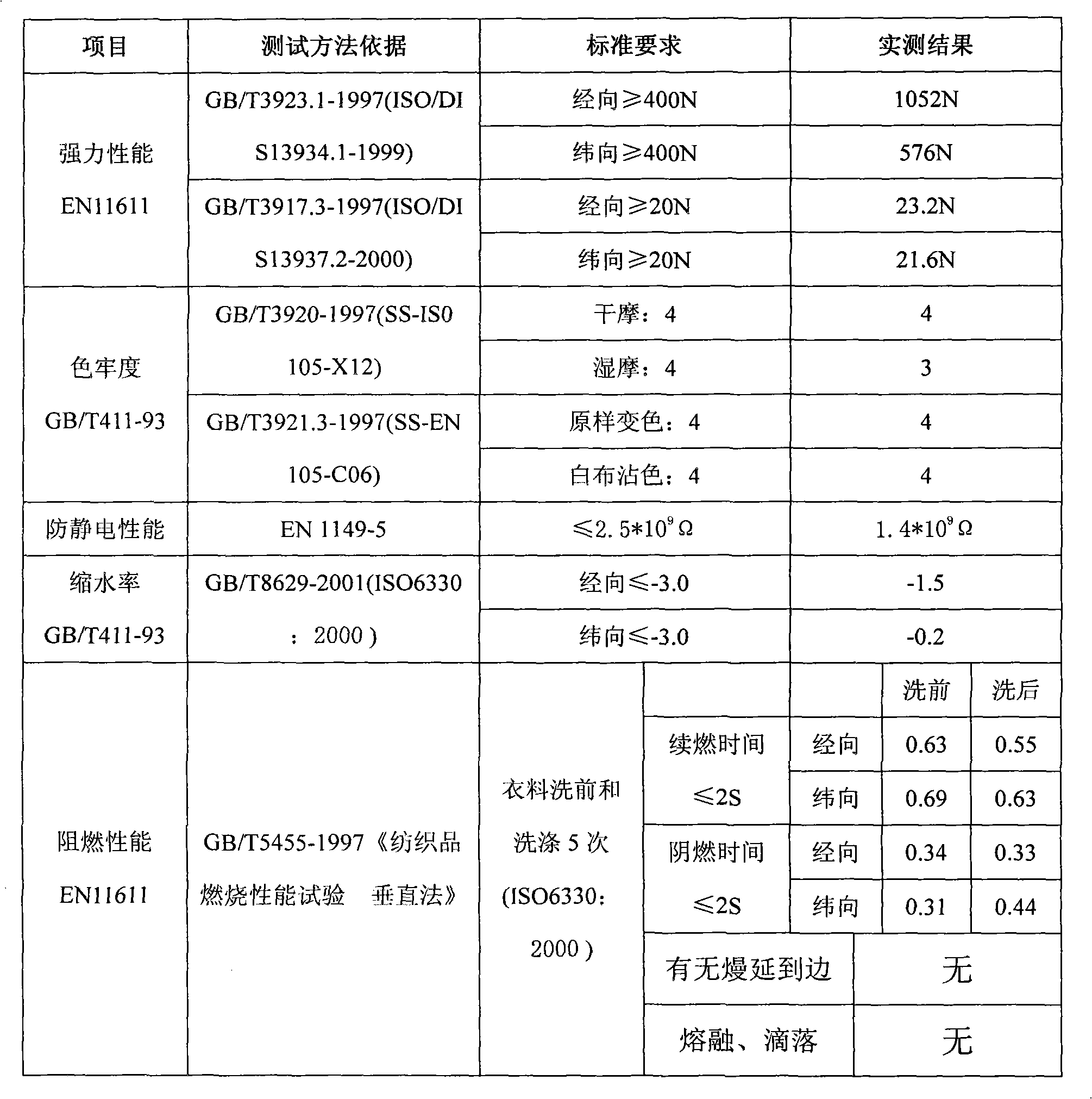

Image

Examples

Embodiment Construction

[0025] A method for processing cotton-polyester antistatic and flame-resistant fabrics, which is characterized in that: sequentially comprising the following steps: dyeing gray cloth after weaving, then padding with flame-retardant liquid, then carrying out ecological finishing, and finally stretching and pre-shrinking to obtain finished products; The gray cloth is a fabric that is woven with organic conductive filaments at equal intervals in the warp or weft direction; the flame retardant liquid is composed of the following components by weight percentage:

[0026] Vinyl phosphate 20-25% (eg 20%, 22%, 25%)

[0027] O, O dimethyl-N-methylolacrylamide phosphate 20-25% (example 20%, 22%, 25%)

[0028] Highly etherified hexamethylol melamine resin 4-10% (example 4%, 7%, 10%)

[0029] Polyethylene resin 1-5% (example 1%, 3%, 5%)

[0030] Phosphoric acid 1-4% (example 1%, 3%, 4%)

[0031] Penetrant JFC 1%

[0032] Deionized water balance.

[0033] In the processing method of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com