Wear-resisting ceramic pneumatic side sliding valve

A technology of wear-resistant ceramics and slide valves, which is applied to slide valves, valve devices, engine components, etc., and can solve problems such as external leakage, easy jamming, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

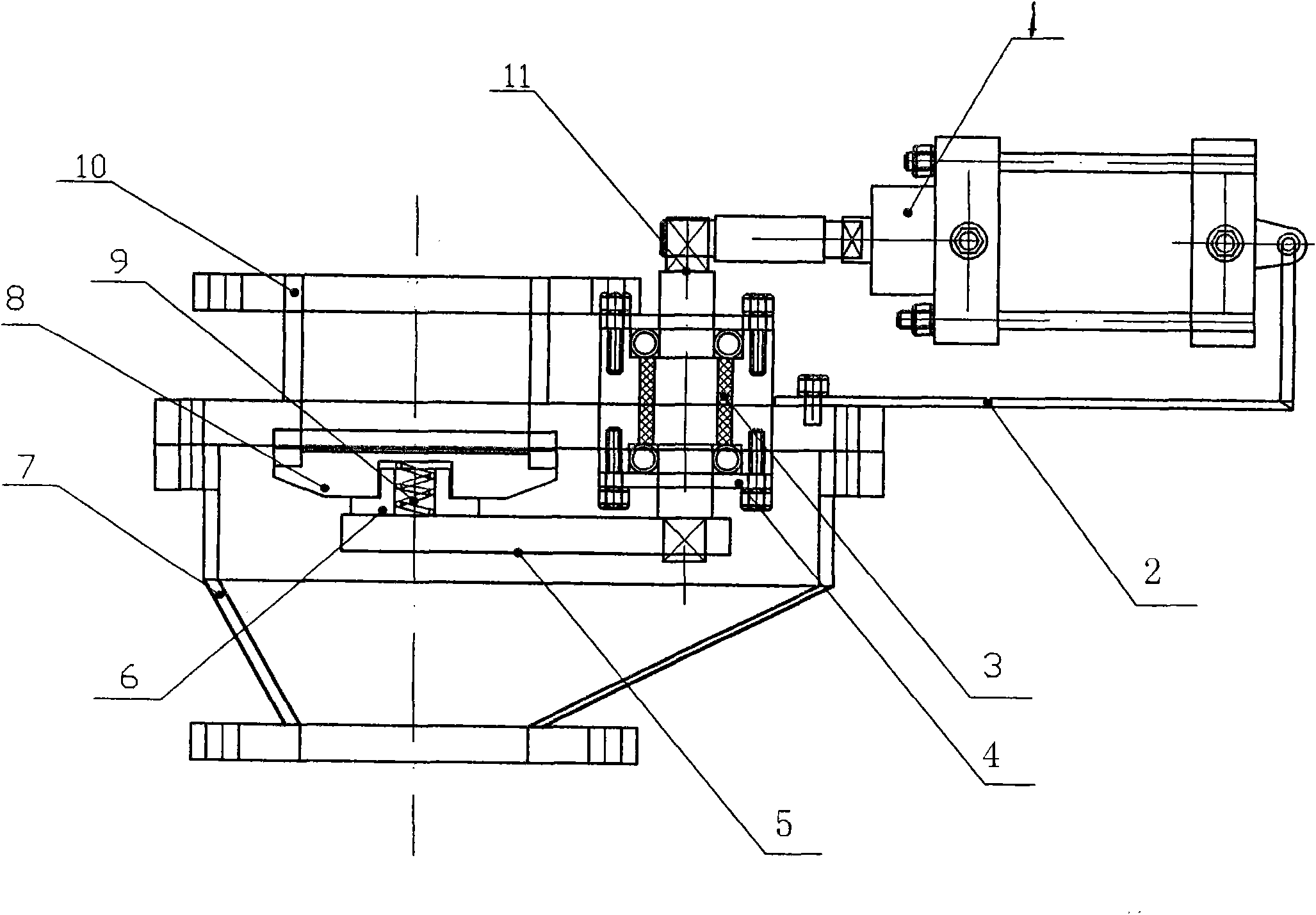

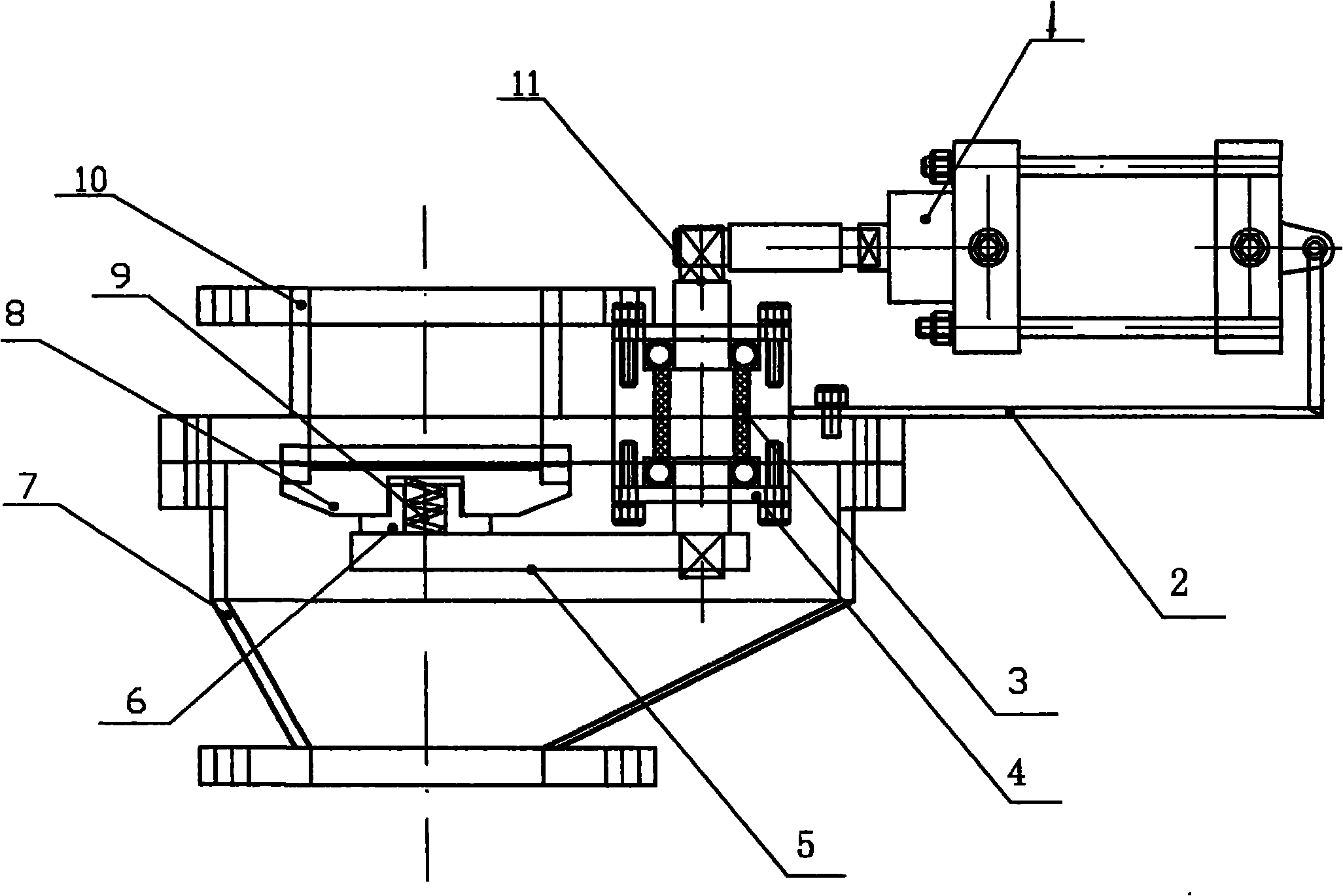

[0006] Specific embodiments: the present invention will be further described below in conjunction with accompanying drawing

[0007] In the figure, a wear-resistant ceramic pneumatic side slide valve of the present invention uses the rotating shaft as the fulcrum, and the horizontal force arm lever moves under the rotation of the rotating shaft so that the ceramic pendulum side slide plate is closely attached to the upper and lower valve bodies. This design can effectively scrape off the sundries on the surface of the ceramic pendulum side slide; in addition, this device adopts the buoyancy technology that assists the compensation spring to cooperate with the ceramic pendulum side slide, which can ensure that the ceramic pendulum side slide is tightly connected to the upper valve body. Contact without any gaps, and there will be no air leakage. During specific implementation, the action execution cylinder is fastened on the cylinder bracket to drive the rotating shaft to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com