Cement mortar stirring device

A mixing device and cement mortar technology, applied in the field of cement mixing, can solve the problems of inconvenient disassembly, difficult cleaning, easy solidification, etc., and achieve the effect of convenient and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

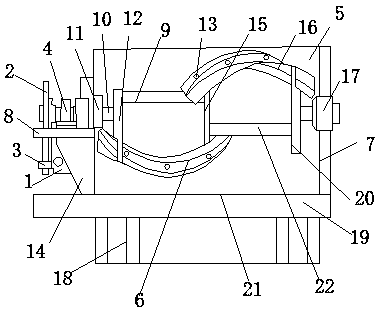

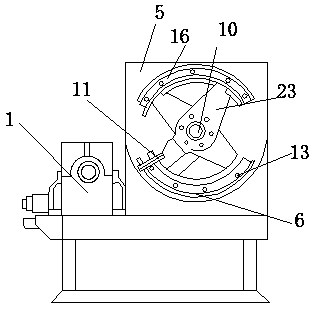

[0024] Example 1: Reference Figure 1-2 , a cement mortar mixing device, including a tank body 21, a prime mover 1, a blade body A6 and a blade body B16, and a side wall sliding contact body 11; the lower surface of the tank body 21 is fixedly connected to the upper surface of the fixed shaft 19, fixed The lower surface of the shaft 19 is fixedly connected with the upper end of the support column 18, the left outer surface of the tank body 21 is fixedly connected with the baffle 8, the left end of the baffle 8 is fixedly connected with the sprocket 2, and the lower surface of the baffle 8 is connected with the upper end of the prime mover baffle 14. Fixed connection, the right side of the prime mover baffle 14 is fixedly connected to the left side of the tank body 21, the prime mover 1 is fixedly installed on the lower surface of the baffle 8, the chain 3 is fixedly installed at the lower end of the sprocket 2, and the upper surface of the baffle 8 is fixedly installed. Rotati...

Embodiment 2

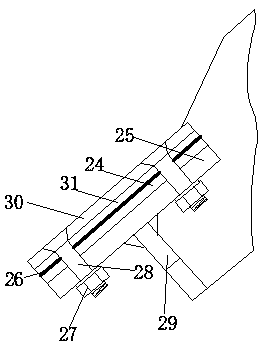

[0027] Embodiment 2: refer to Figure 3-4 , combined with the basis of Embodiment 1, the side wall sliding contact body 11 includes a support arm 29 and a screw rod 28, the upper end of the support arm 29 is fixedly connected to the inner wall of the left side of the tank body 21, the lower end of the support arm 29 is fixedly connected to the upper end of the fixed plate 25, and fixed The lower surface of the plate 25 is fixedly connected with the slidable rubber plate 24, the lower surface of the slidable rubber plate 24 is provided with a synthetic resin cloth 26, the lower surface of the synthetic resin cloth 26 is fixedly connected with a plastic rubber plate 31, and the lower surface of the plastic rubber plate 31 is fixedly connected with a The polymer plate 30, the bottom end of the screw rod 28 runs through the fixed block 25, the slidable rubber plate 24, the synthetic resin cloth 26 and the plastic rubber plate 31 are fixedly connected with the inner bottom surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com