Wall potential optimization method for reducing sample bandwidth in electric microfluidic chip

A technology of microfluidic chip and optimization method, which is applied in the direction of analyzing materials and instruments, which can solve the problems of fluid temperature rise, easy generation of Joule heat, and accelerated axial diffusion of samples, so as to achieve the effect of reducing requirements and reducing axial diffusion

Inactive Publication Date: 2010-12-22

CHINA JILIANG UNIV

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

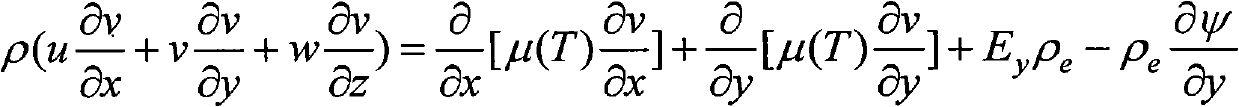

The voltage applied to both ends of the channel of general chip electrophoresis is several thousand volts per meter. Under such a high voltage, Joule heat is easily generated. The specific heat source can be expressed as λ·E 2 , where λ is the conductivity of the electrolyte solution in the micropipe, E is the electric field strength, and it will cause the temperature of the fluid in the micropipe to increase, and produce a radial and axial temperature gradient, these factors will accelerate the sample Axial diffusion, which reduces the detection effect, see Knox 【11】

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

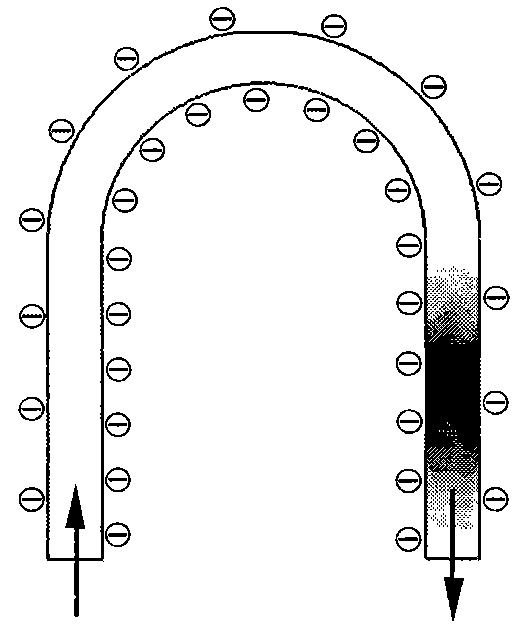

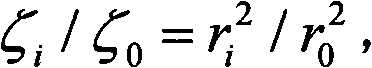

The invention relates to a wall potential optimization method for reducing sample bandwidth in an electric microfluidic chip, which comprises improvement of wall potential of inner and outer curved channels in the microfluidic chip and optimization of wall potential of a flat pipeline at an outlet in the microfluidic chip. The invention is characterized in that the velocity profile in the pipeline of the microfluidic chip is adjusted by changing distribution and magnitude of the wall potential, thereby reducing the axial diffusion caused by Joule heat and the curved channels, wherein the wall potential distribution of the curved channel parts meets the condition that the potential distribution of the flat pipeline at the outlet is zeta / GT. The invention comprehensively considers the influence of the Joule heat and the curved channel effect on sample diffusion and can effectively reduce the axial diffusion of samples in the curved channels driven by electroosmotic flow; and the invention is suitable for curved channels with various curved angles and has no need of processing curved channels with complex geometric shapes, thereby lowering the requirement of the processing technology.

Description

technical field The invention relates to the field of microfluidic chips, in particular to a wall potential optimization method for reducing sample bandwidth in electrodynamic microfluidic chips. Background technique In recent years, with the rapid development of microfluidic lab-on-a-chip, electroosmosis has also been applied to the drive and control of nanoscale microfluidics, the mixing and separation of samples, etc., so that it can be used in biological and chemical analysis and disease is one of the most successful microfluidic actuation and control methods. In flow devices at the micron or nanometer scale, electroosmotic drive has the following two advantages compared with pressure drive: First, the fluid velocity in the electroosmotic flow field has nothing to do with the cross-sectional area of the pipe or channel in a large range , which is beneficial to the driving and control of fluid at the microscale; while in pressure driving, in order to ensure a certain f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N35/00

Inventor 张凯林建忠于明州

Owner CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com