Rotary label and method for monitoring photolithographic quality using same

A marking and photolithography technology, which is applied in the direction of microlithography exposure equipment, optics, photoplate making process of pattern surface, etc., can solve problems such as difficult to distinguish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

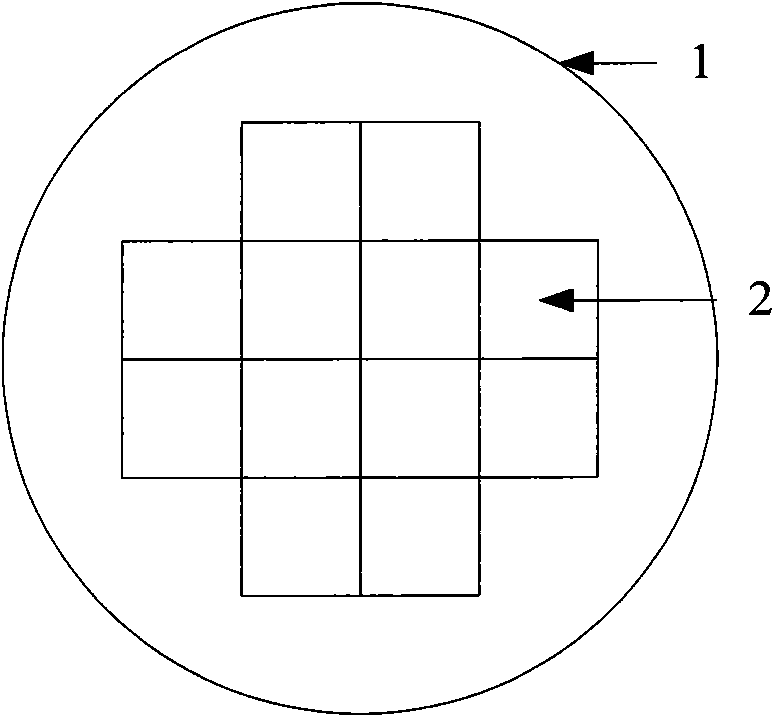

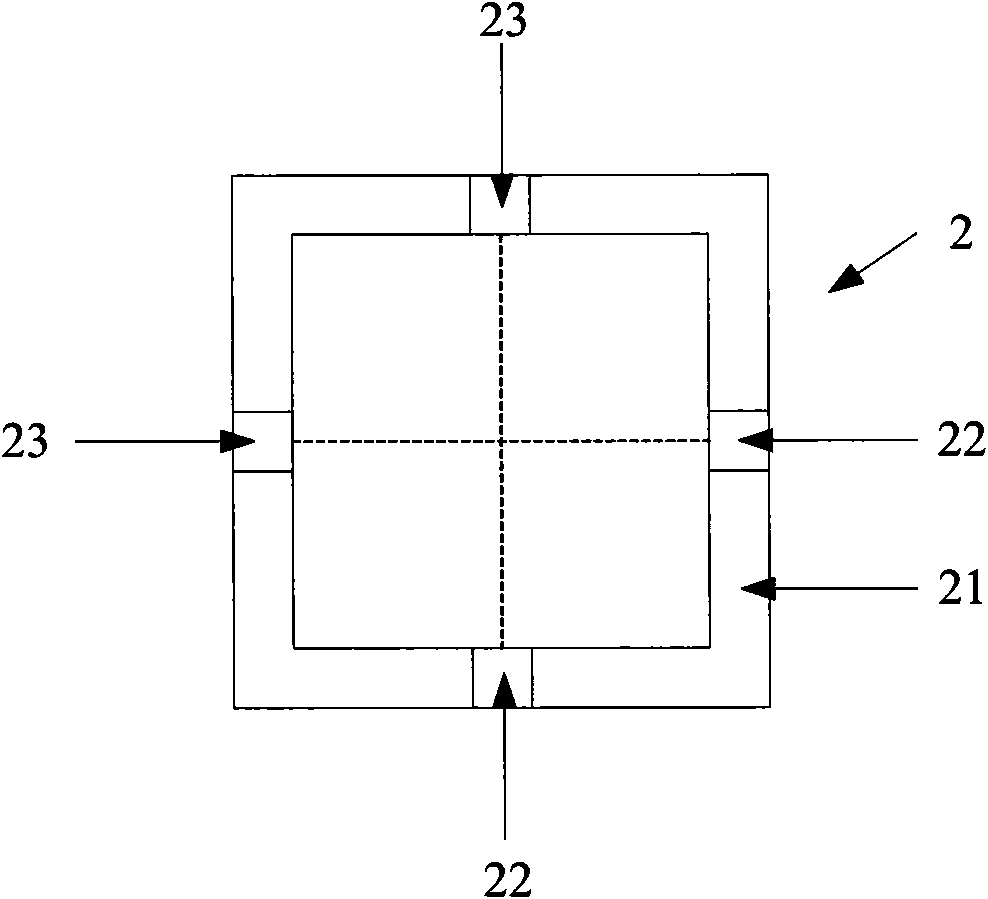

[0035] The rotation mark of the present invention is on the projection mask in the exposure step of the photolithography process, usually there is a rotation mark on the top, bottom, left and right of a projection mask.

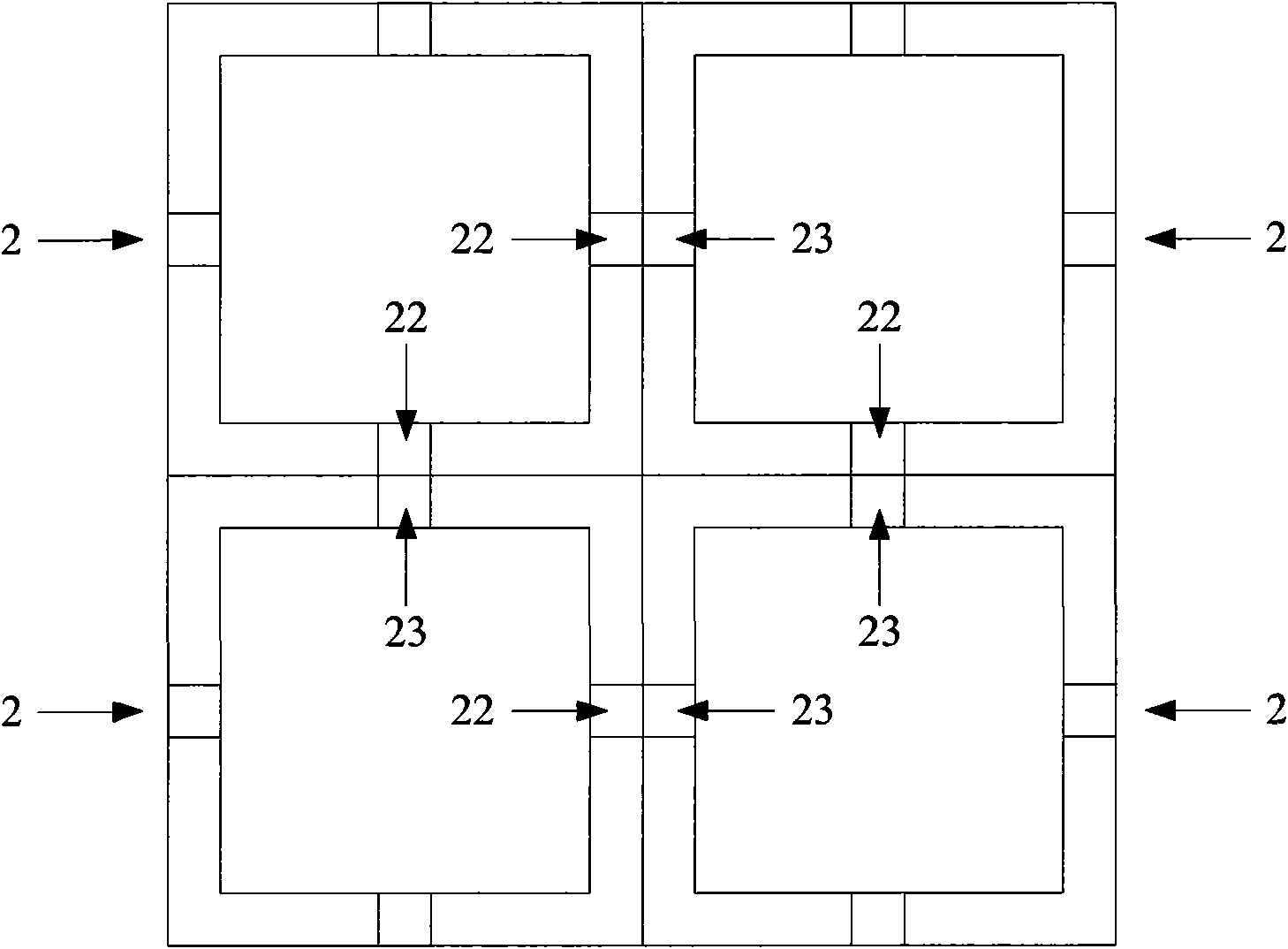

[0036] When there is a windmill-shaped cutting line on the projection mask, the windmill-shaped cutting line includes four pieces, and each cutting line has a rotation mark near the center line of the projection mask, such as Image 6 shown. After exposure, the two exposure units adjacent up and down have the graphics of two rotation marks adjacent to the left and right, and the two exposure units adjacent to the left and right have the graphics of two rotation marks adjacent up and down, such as Figure 7 shown.

[0037] see Figure 8 The rotary mark 5 of the present invention is a strip-shaped transparent zone 51 with equal width (set as a) on the opaque projection mask, and there is an equal width (set as b) between every two transparent zones 51. For t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com