Organic electroluminescent device, method for manufacturing the same, surface light source, illuminating device and display device

An electroluminescence element and luminescence technology, which is applied in the manufacture/processing of organic light-emitting devices, electroluminescence light sources, organic light-emitting devices, etc., and can solve the problems of large color changes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109]

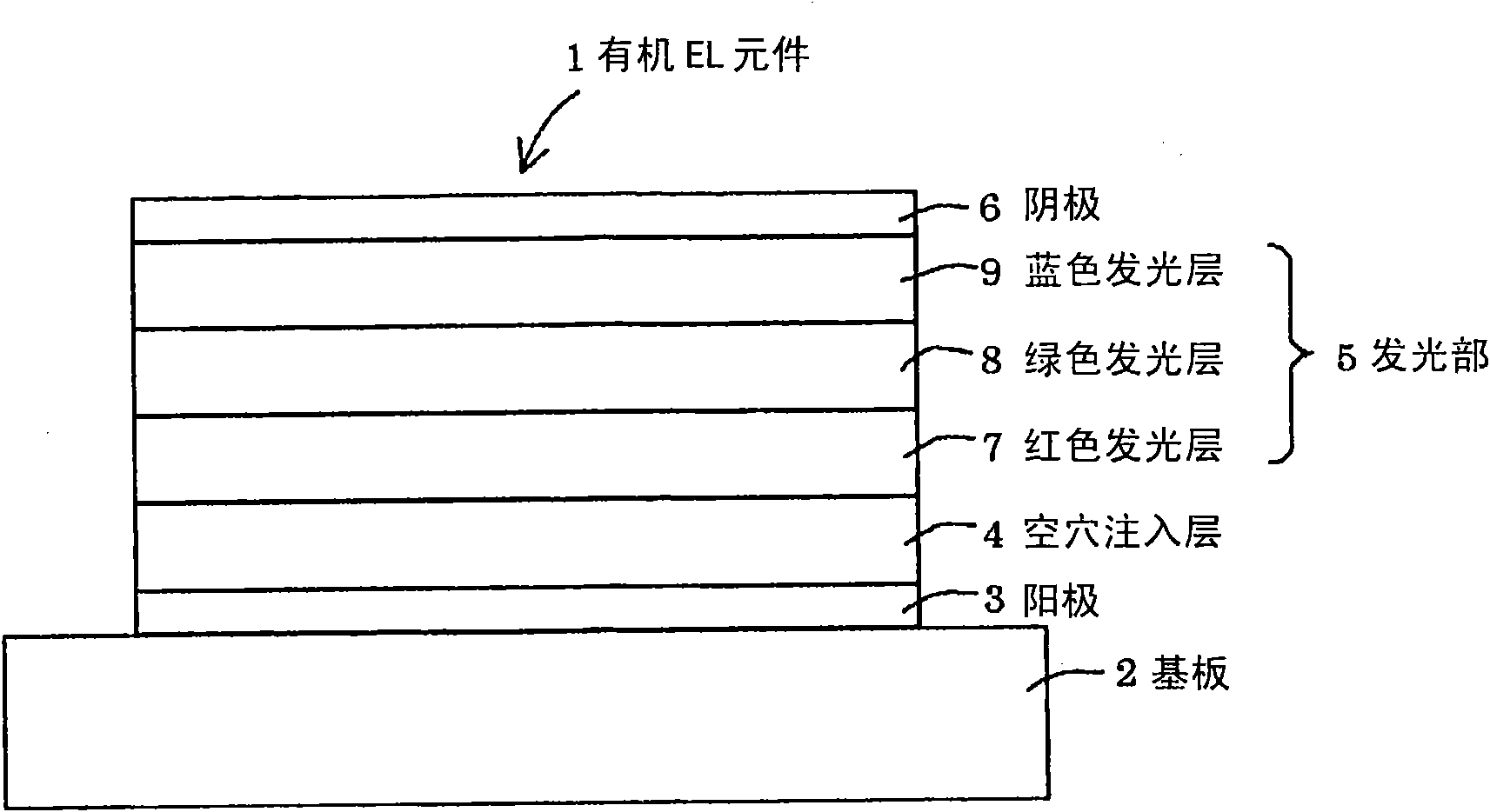

[0110] As an example, make figure 1 The organic EL element shown. A glass substrate was used as the substrate 2 , and a film was formed on the glass substrate by a sputtering method, and an ITO film patterned in a predetermined shape was used as the anode 3 . As the anode 3, a material having a thickness of 150 nm was used. After cleaning the substrate 2 with the anode 3 with alkaline detergent and ultrapure water and drying it, use UV-O 3 Device (manufactured by TECHNOVISION, trade name "model 312 UV-O 3 Clean System") for UV-O 3 deal with.

[0111] Next, a suspension of poly(3,4)ethylenedioxythiophene (poly(3,4)ethylenedioxythiophene) / polystyrenesulfonic acid (manufactured by H.C. Starck-VTech, trade name "BaytronP TP AI4083") was used Filter through a membrane filter with a pore size of 0.2 μm. The filtered liquid is spin-coated on the anode 3 to form a thin film. Next, heat treatment was performed at 200° C. for 10 minutes on a hot plate to obtain a hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com