Yarn with function of absorbing daylight infrared rays and textile

A technology of infrared rays and textiles, applied in textiles, papermaking, textiles, yarns, etc., can solve the problems of unsuitable cost, low thermal insulation textiles, expensive textiles, etc., and achieve the effect of avoiding excessive fluffy and less color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

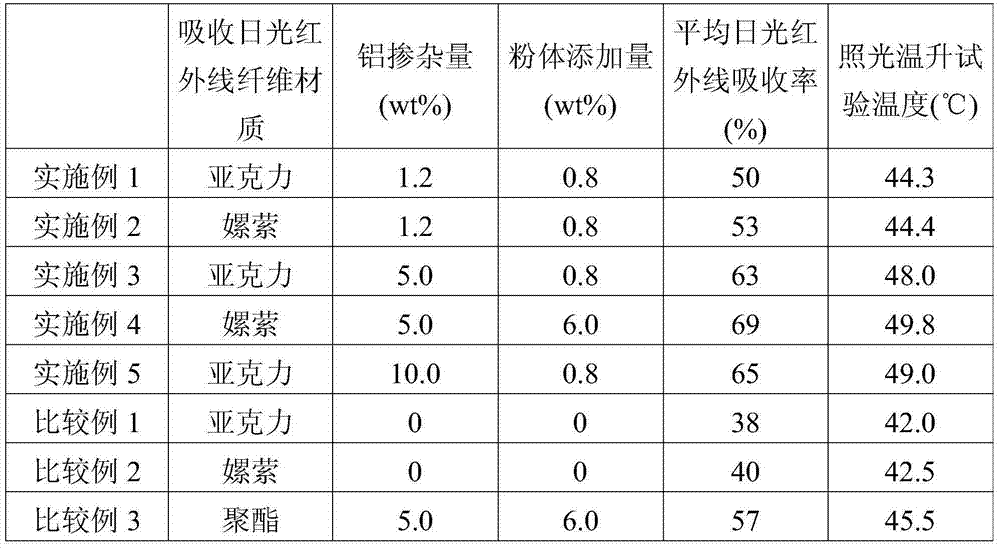

[0027] Example 1 - Acrylic fiber containing zinc oxide powder doped with aluminum

[0028]The zinc oxide powder doped with aluminum (the doping amount of aluminum is 1.2wt% of the total weight of zinc and aluminum) is dispersed in polyacrylonitrile in dimethylacetamide (DMAc) solution, wherein polyacrylonitrile and doped Based on the total weight of the aluminum-doped zinc oxide powder, the powder addition amount is 0.8 wt%, and the usage amount of DMAc is 85 wt%. Acrylic fibers of 2.0d and 51mm are made by spinning process, and then blended with nylon 6 / rayon / wool to make 2 parts of acrylic / nylon 6 / rayon / wool (weight ratio 61 / 18 / 15 / 6). / 48s yarn, and finally made into 12-needle knitting pieces. The fabric of Example 1 was subjected to a solar infrared light temperature rise test, and the measured temperature was 44.3° C.; the fabric of Example 1 was tested for solar infrared absorptivity, using a Japanese Jasco V-570 spectrum analyzer (the extraction wavelength range is 1,0...

Embodiment 2

[0031] Example 2 - Rayon fibers containing aluminum-doped zinc oxide powder

[0032] The zinc oxide powder doped with aluminum (the doping amount of aluminum is 1.2wt% of the total weight of zinc and aluminum) is dispersed in the sodium sulfonate cellulose alkali mucus, wherein the zinc oxide powder doped with aluminum and regenerated fiber Based on the total weight of the element, the powder addition amount is 0.8wt%. The rayon fibers of 1.2d and 38mm are made by spinning process, and then blended with cotton fibers to make rayon / cotton (weight ratio 60 / 40) 30s / 1 yarn, and the final fabric weight is 200g / m 2 circular knitting machine knitted fabric. The circular knitting machine knitted fabric of embodiment 2 is carried out the illumination temperature rise test of sunlight infrared rays, and the temperature measured by the sunlight infrared lamp illumination temperature rise lamp box of Taiwan TN-037 verification standard is 44.4°C; the circular knitting machine knitting fa...

Embodiment 3

[0035] Example 3 - Acrylic fiber containing zinc oxide powder doped with aluminum

[0036] The difference between Example 3 and Example 1 lies in the zinc oxide powder doped with aluminum, and the doping amount of aluminum is 5.0wt% of the total weight of zinc and aluminum. Acrylic fibers of 2.0d and 51mm are made by spinning process, and then blended with nylon 6 / rayon / wool to make 2 parts of acrylic / nylon 6 / rayon / wool (weight ratio 61 / 18 / 15 / 6). / 48s yarn, and finally made into 12-needle knitting pieces. The solar infrared light temperature rise test was carried out on the woven sheet of Example 3, and the measured temperature was 48.0°C; the solar infrared absorptivity test was carried out on the woven sheet of Example 3 (the extraction wavelength range was 1,000-2,500nm), and the measured The average absorption rate is 63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com