blender

A technology for mixers and mixing tanks, which is applied to mixer accessories, mixers, mixers with rotating containers, etc., which can solve the problems of time-consuming cleaning of mixers and easy residual impurities in the machine, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

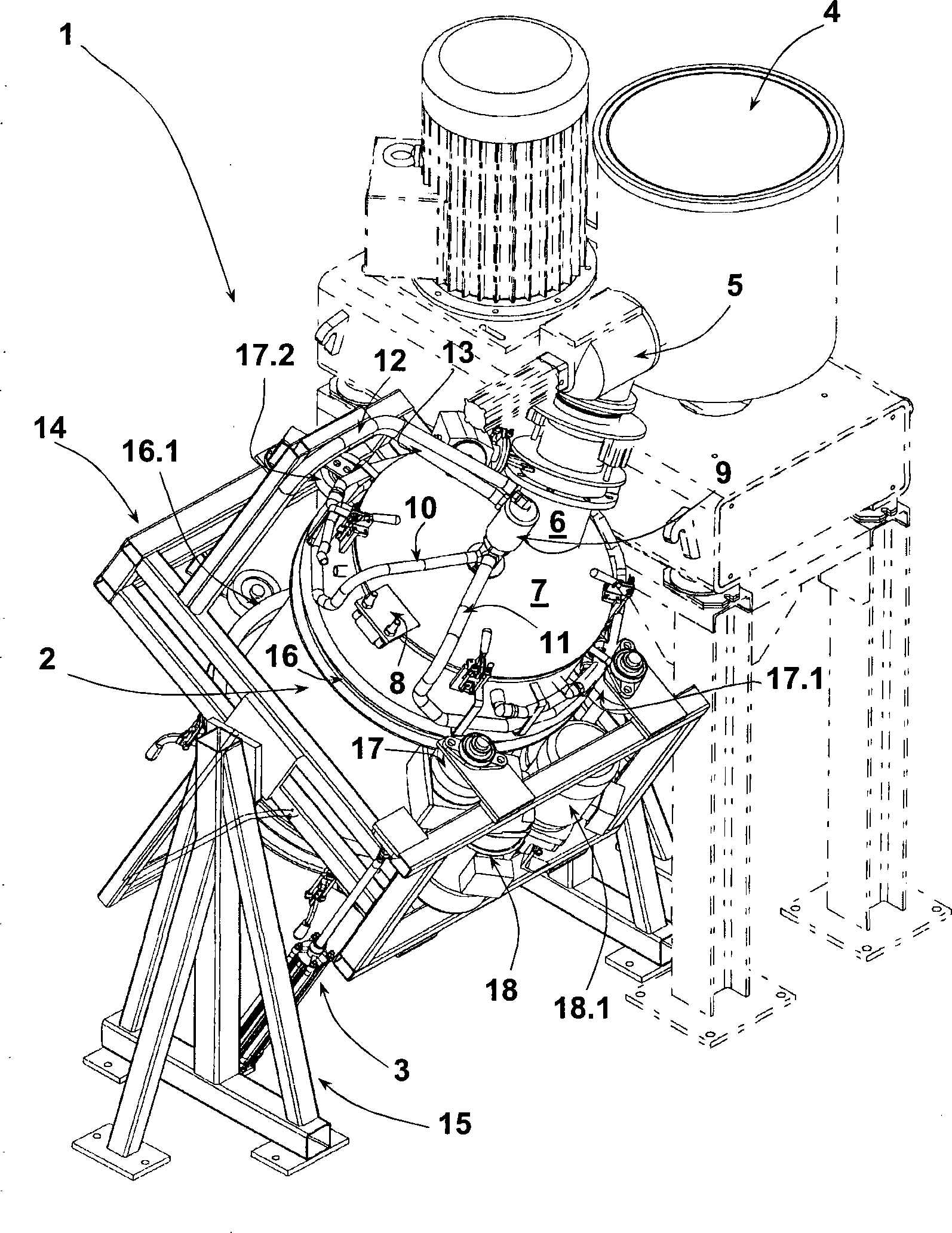

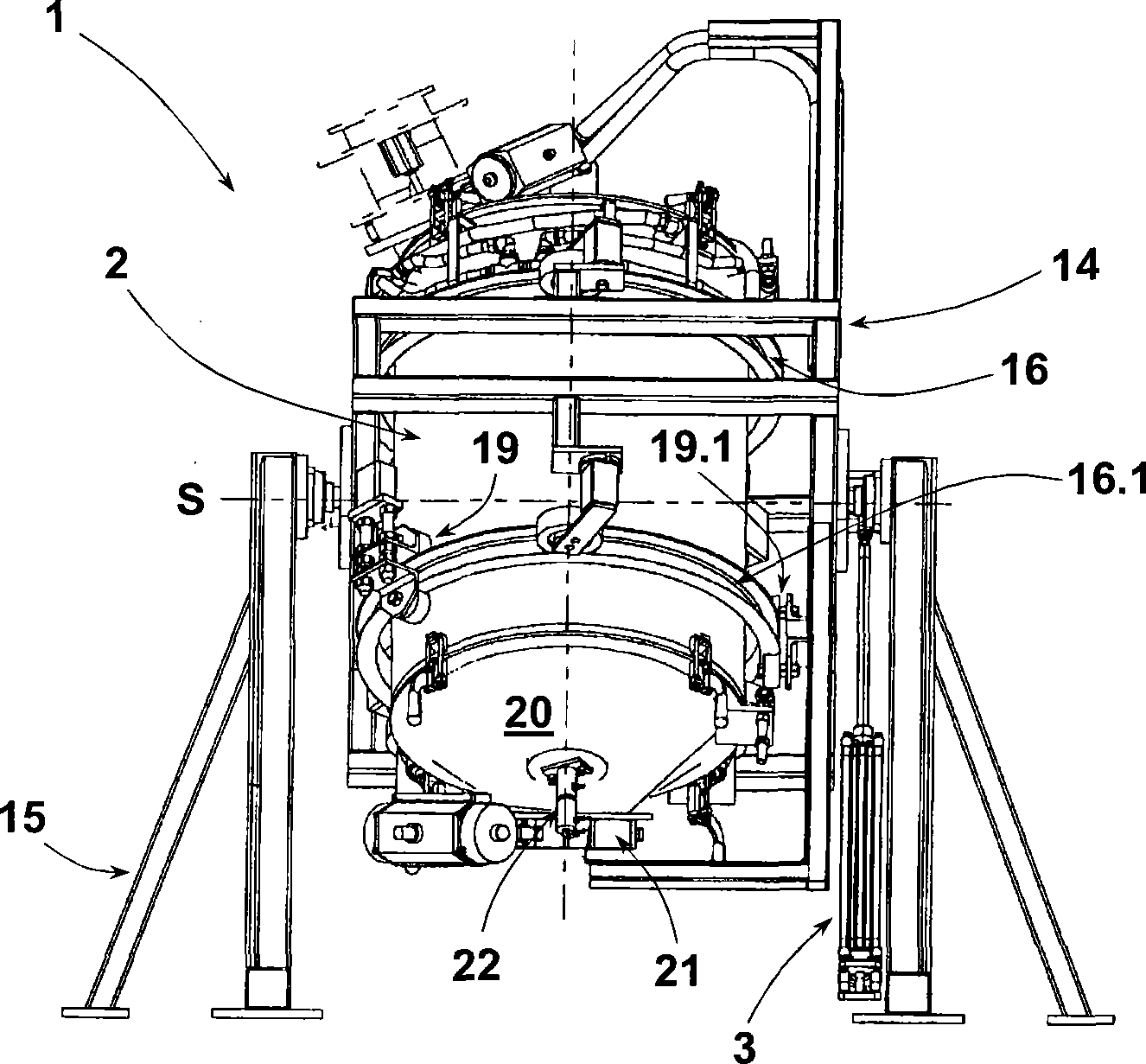

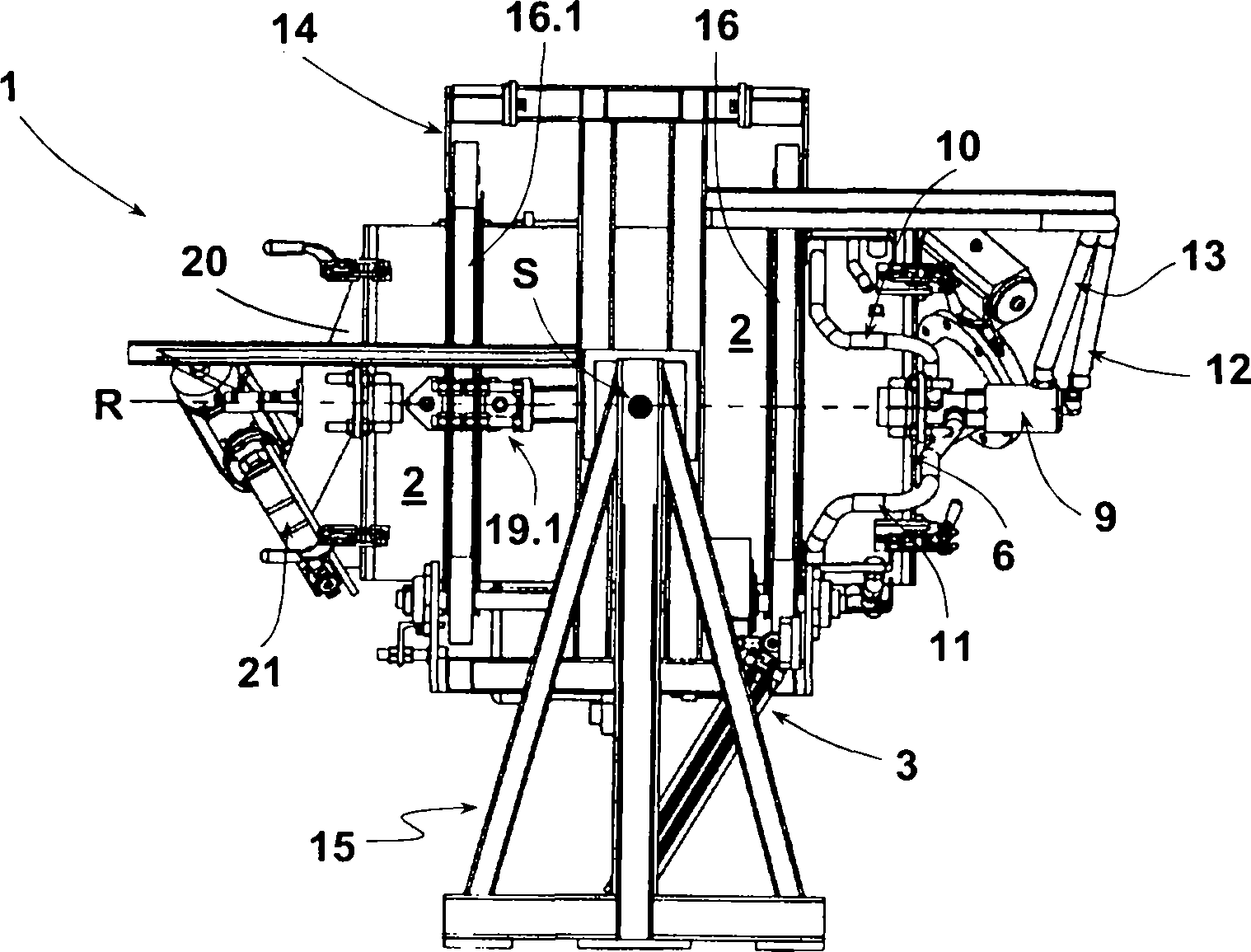

[0047] The present invention is designed as a cooling mixer 1, which contains a mixing bucket 2, which surrounds a horizontal swing axis S by adjusting a cylinder 3 (compare to image 3 ) to swing. exist figure 1 , shows a schematic diagram of the cooling mixer 1 and the main mixing tank 2, figure 1 is a schematic diagram of the feeding state. The feed state is also the static state of the adjustment cylinder 3. figure 1 The dotted line part next to the middle cooling mixer 1 is the heating mixer 4, and the outlet of the heating mixer 4 is also the feed inlet 5 of the cooling mixer 1, and the top of the mixing bucket 2 is connected with the feed inlet 5 by a pneumatic movable coupling. The hinged barrel is realized through the feeding hub 6. This connection method establishes a connection path from the feeding port 5 to the mixing drum 2. The inside of the feeding port 5 is provided with a baffle structure, and the baffle can be opened and closed to play a role. For the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com