BOPP (Biaxially-Oriented Polypropylene) slot-free holographic film and preparation method thereof

A technology of no plate seam and holographic film, which is applied in temperature recording method, printing of special varieties of printed matter, decorative art, etc., can solve the problems of material waste and trouble, achieve material saving, convenient application, and avoid unqualified manual picking product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

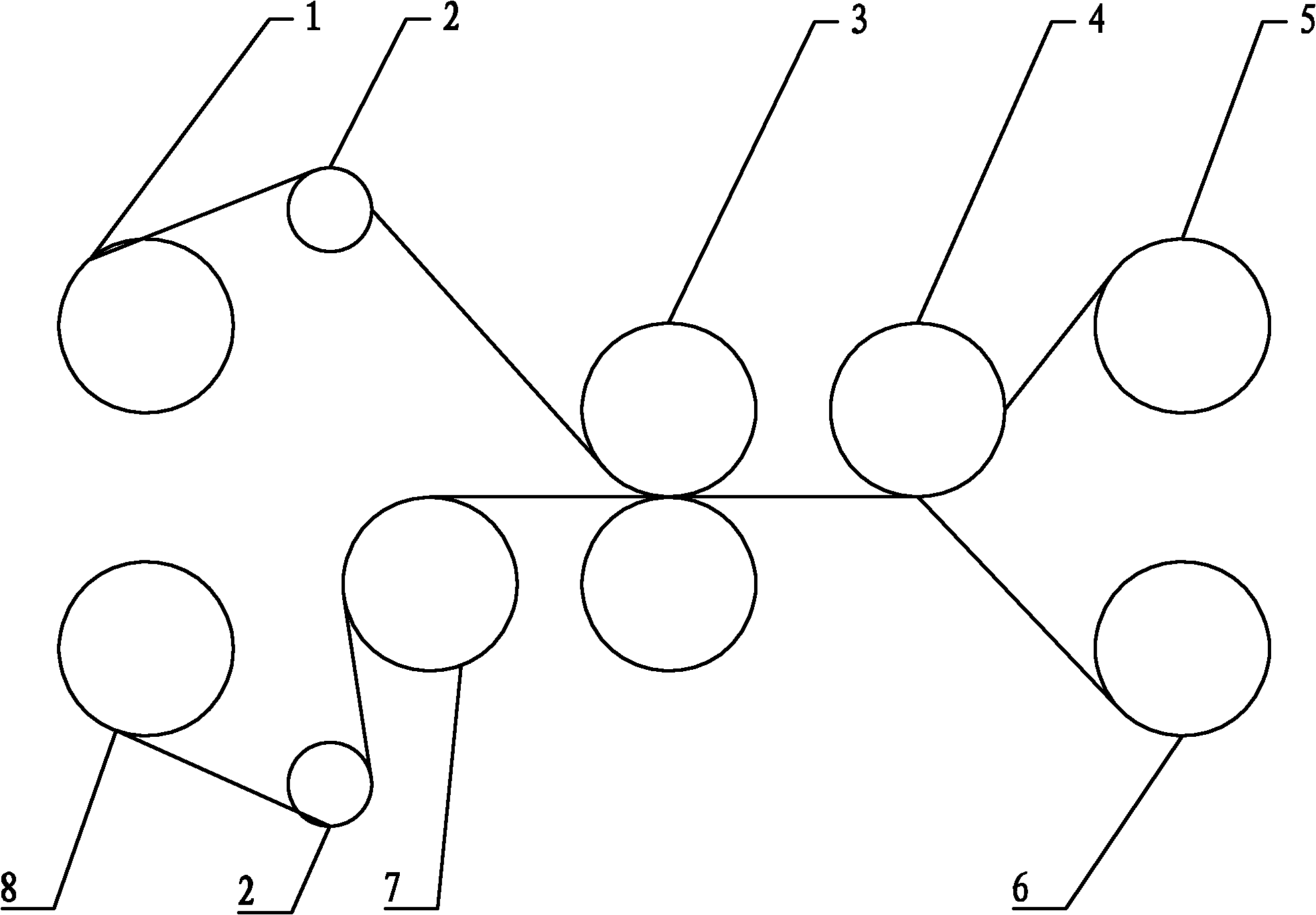

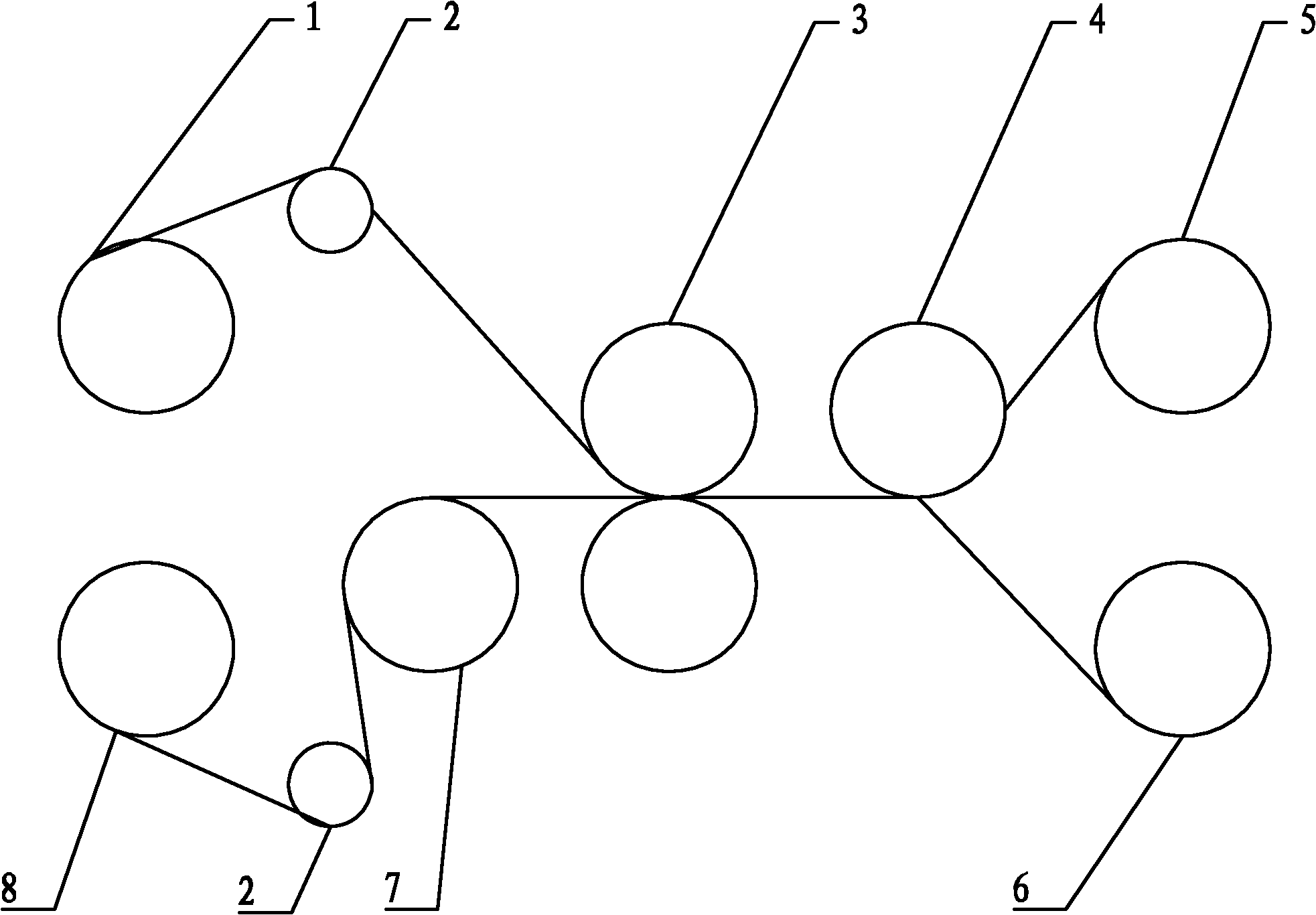

[0025] Such as figure 1 As shown, the method for making BOPP seamless holographic film is characterized in that it comprises the following steps:

[0026] 1) Unwinding: The continuous plate unwinding device 1 and the BOPP base film unwinding device 8 constitute an unwinding unit, and the continuous plate and the BOPP base film are unwound synchronously;

[0027] 2) Preheating: BOPP base film is first heated to 120-150°C in the preheating unit;

[0028] 3) Embossing: The preheated BOPP base film and the seamless continuous plate are compositely embossed in the embossing unit 3 to obtain a seamless BOPP film. The embossing temperature is less than 50°C and the embossing pressure is 0.1-0.5 MPa, the embossing speed is 20-50m / min;

[0029] 4) Cooling: the BOPP film is peeled off from the continuous plate after being cooled by the cooling unit 4;

[0030] 5) Winding: The continuous plate winding device 5 and the BOPP holographic film winding device 6 constitute a winding unit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com