Method and equipment for separating volatile organic matters from fermentation product in situ

A volatile, in-situ separation technology, used in separation methods, biochemical equipment and methods, distillation separation, etc. Separation Efficiency, Reduced Treatment Costs, and Effect of Reducing Separation Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

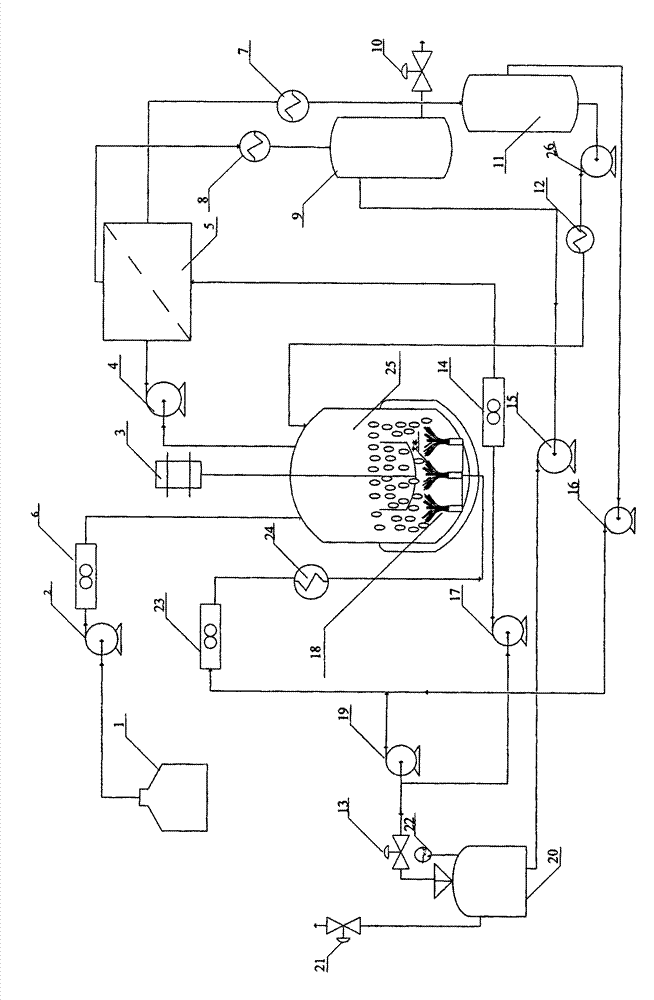

[0026] Example 1: Using starch as raw material for CO 2 and H 2 Preparation of Butanol-Acetone-Ethanol (ABE) by Mixed Gas Circulation Stripping / Steam Permeation In-Situ Separation Coupling Process

[0027] The starch raw material enters the fermentation process through liquefaction and saccharification. according to figure 1 Assemble equipment, adopt 2L fermentation tank, inoculate according to 5% (v / v) inoculum amount, make the culture volume of fermentation tank be 1L, fermentation temperature is controlled at 37 ℃, stirring speed 150r / min. When the fermentation is carried out to 20 hours (h), the concentration of butanol in the fermentation broth is 4-5g / l, the stirring is turned off, and the inert gas CO 2 and H 2 mixed gas (or CO 2 or N 2 ) to start air stripping, the ventilation rate is 3000ml / min. The mixed gas from the fermenter enters the steam permeation device, the temperature of the steam permeation device is controlled at 37°C, and the other side of the ste...

Embodiment 2

[0028] Example 2: Using starch as raw material for CO 2 Production of Ethanol by Circulating Gas Stripping / Steam Permeation In-Situ Separation Coupling Process

[0029] The starch raw material enters the fermentation process through liquefaction and saccharification process, according to figure 1 Assemble equipment, adopt 2L fermentation tank, inoculate according to 5% (v / v) inoculum amount, make the culture volume of fermentation tank be 1L, fermentation temperature is controlled at 35 ℃, stirring speed 150r / min. Fermentation is carried out to 24 o'clock, the concentration of ethanol in the fermented liquid is 70g / l, close stirring, feed inert gas CO 2 Start gas stripping, the ventilation rate is 3000ml / min. The mixed gas from the fermenter enters the steam permeation device, the temperature of the steam permeation device is controlled at 35°C, and the other side of the steam permeation device is filled with CO 2 Purge and dehydrate. The gas dehydrated by steam permeation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com