Method for mounting dry quenching circulating fan

A circulating fan and installation method technology, which is applied in coke oven, coke cooling, petroleum industry, etc., can solve the problems of complex, unreasonable, and unscientific installation process, and achieve the effect of simple debugging method and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

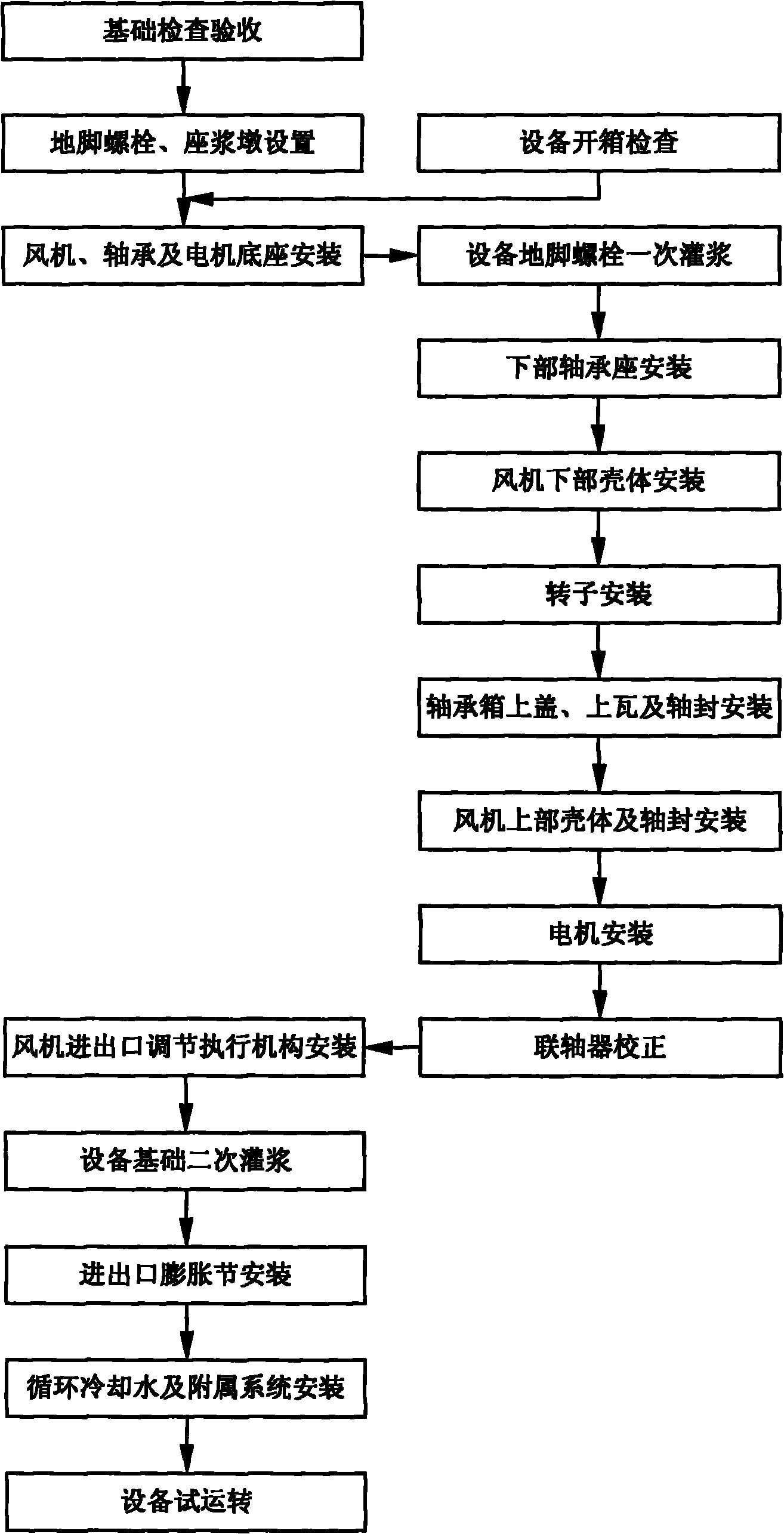

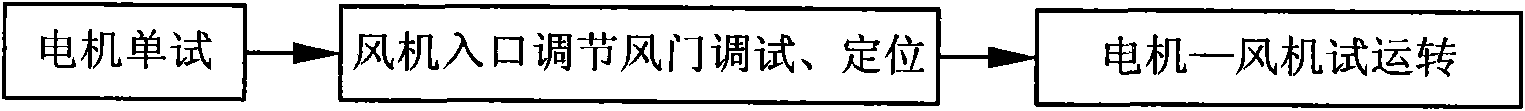

[0018] A CDQ circulating fan installation method, which is carried out in sequence as follows: a. Basic inspection and acceptance, b. Anchor bolts, seat slurry pier setting and equipment unpacking inspection, c. Fan, bearing and motor base installation, d. One-time grouting of equipment anchor bolts, e. installation of lower bearing seat, f. installation of fan lower casing, g. rotor installation, h. bearing box upper cover, upper tile and shaft seal installation, i. fan upper casing and shaft seal Installation, j. Motor installation, k. Coupling correction, l. Fan inlet and outlet adjustment actuator installation, m. Equipment foundation secondary grouting, n. Import and export expansion joint installation, o. Circulating cooling water and auxiliary system installation and p. Equipment trial operation.

[0019] Complete the following construction preparations before commissioning:

[0020] 1. Preparation of technical data

[0021] (1) The CDQ circulating fan installation di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com