Edible fungi liquid strain biological fermentation tank

The technology of biological fermentation tank and liquid strain is applied in the field of fermentation tank, which can solve the problems of uneven gas entering the tank, inability to achieve oxygen supply, mycelium damage, etc., and achieve uniform oxygen supply and stirring, effective and uniform oxygen supply, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

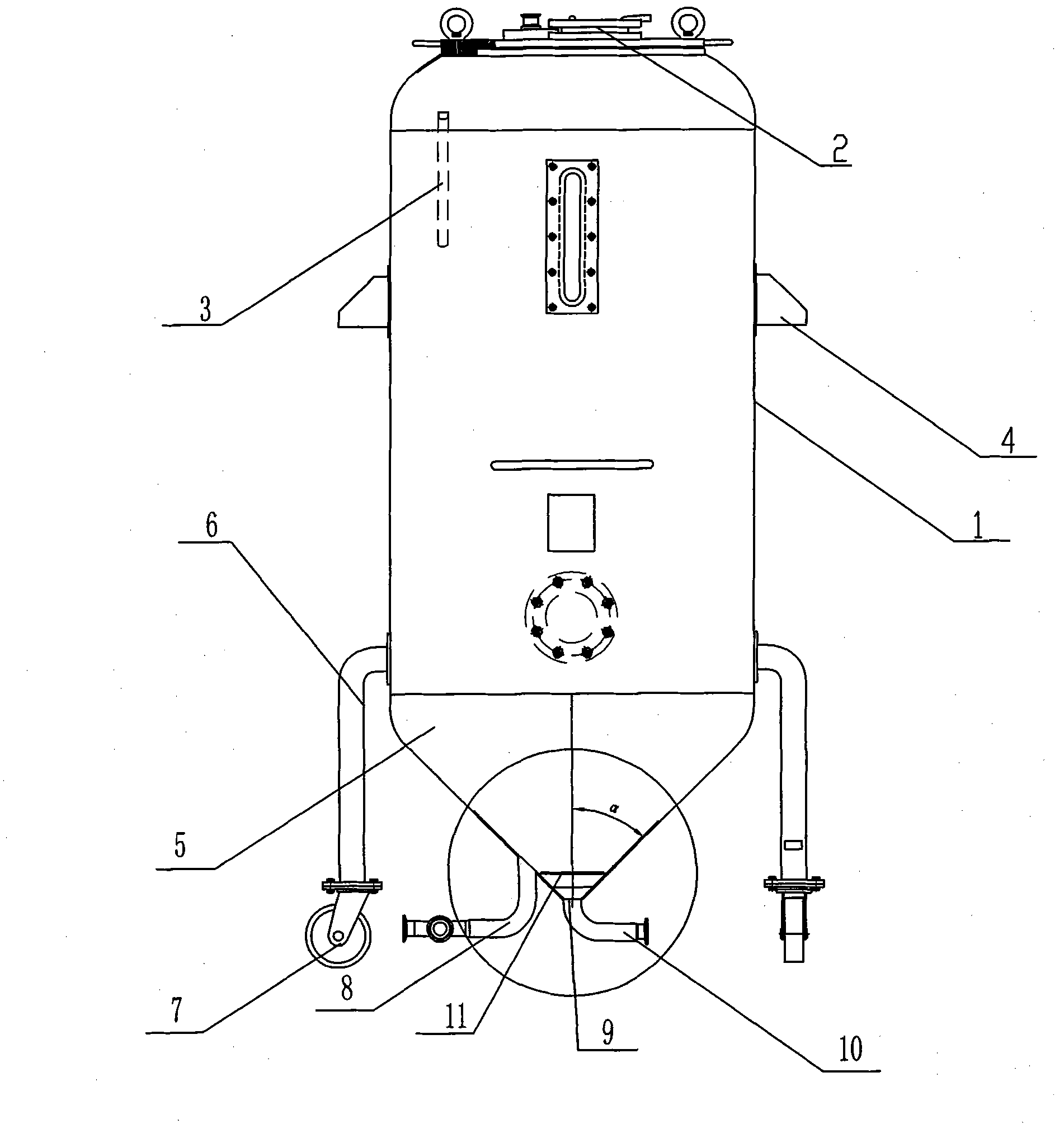

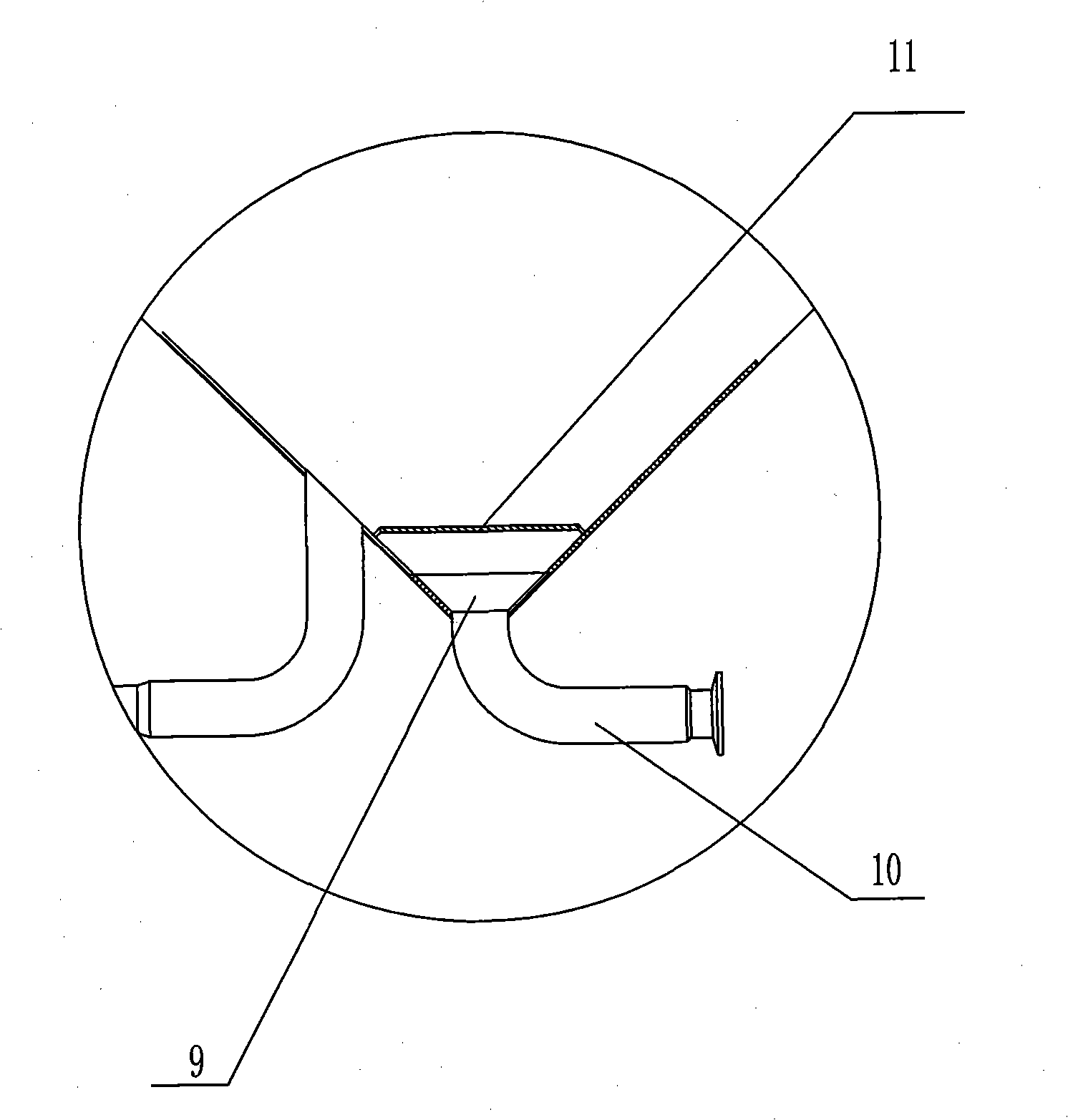

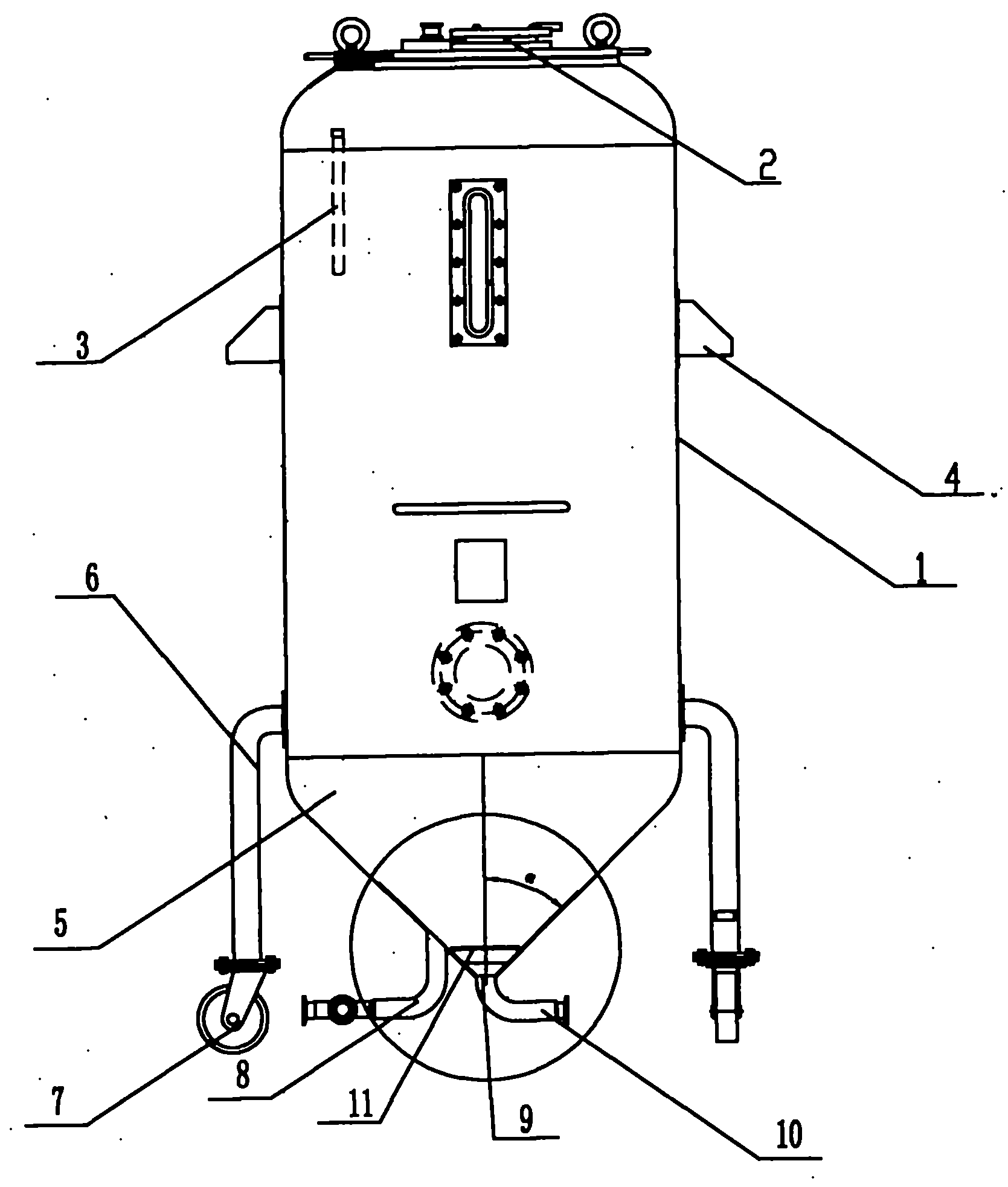

[0018] Example 1. refer to figure 1 , 2 . A biological fermentation tank for edible fungus liquid strains, comprising a tank body 1 with a feed inlet 2 on the top; The air port 9 and the air inlet 9 are connected with an air inlet pipe 10, and the lower head 5 above the air inlet 9 is fixed with a baffle plate 11, and an air passage is formed between the baffle plate 11 and the inner wall of the lower head 5.

Embodiment 2

[0019] Example 2. refer to figure 1 , 2 . A biological fermentation tank for edible fungus liquid strains, comprising a tank body 1 with a feed inlet 2 on the top; The air port 9 and the air inlet 9 are connected with an air inlet pipe 10, and the lower head 5 above the air inlet 9 is fixed with a baffle plate 11, and an air passage is arranged on the baffle plate 11.

Embodiment 3

[0020] Example 3. In the edible fungus liquid strain bio-fermentation tank described in Example 1 or 2: the lower head 5 is conical, the baffle plate 11 is circular, and the air passage is annular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com