Preparation method and application of magnesium-doped porous nano titanium oxide coating

A nano-titanium oxide, coating technology, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., to achieve the effect of fast proliferation rate, good biocompatibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

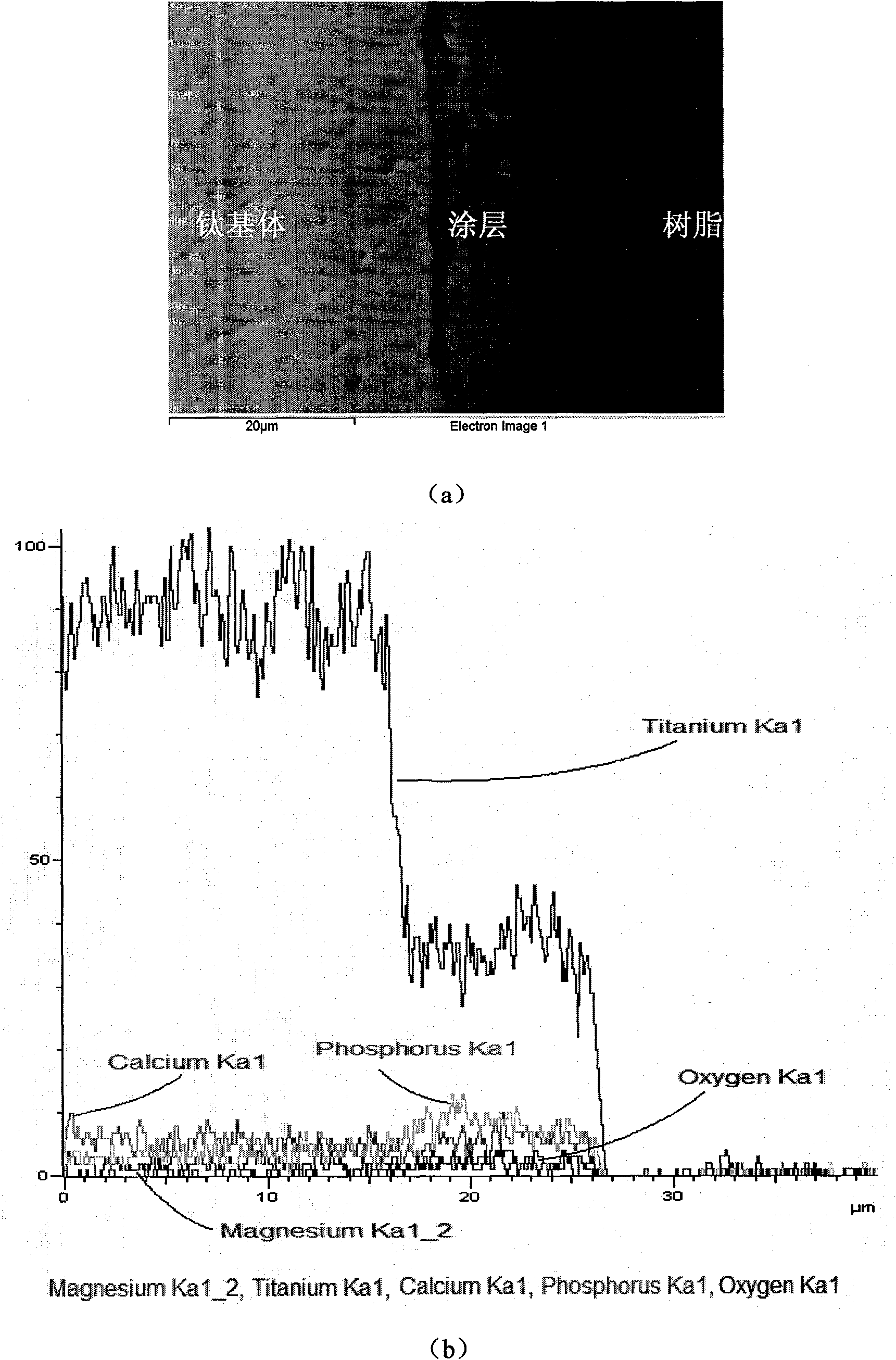

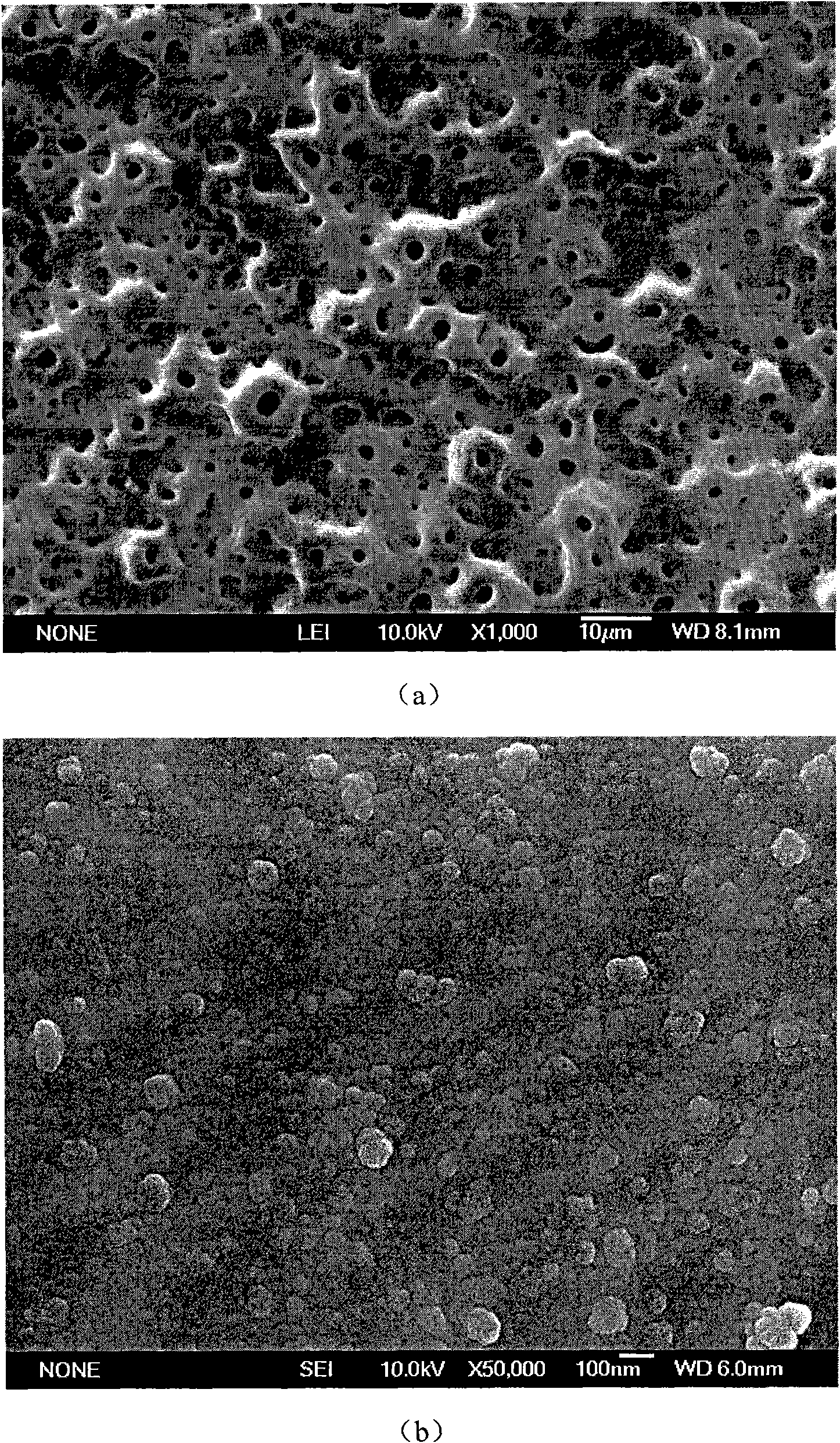

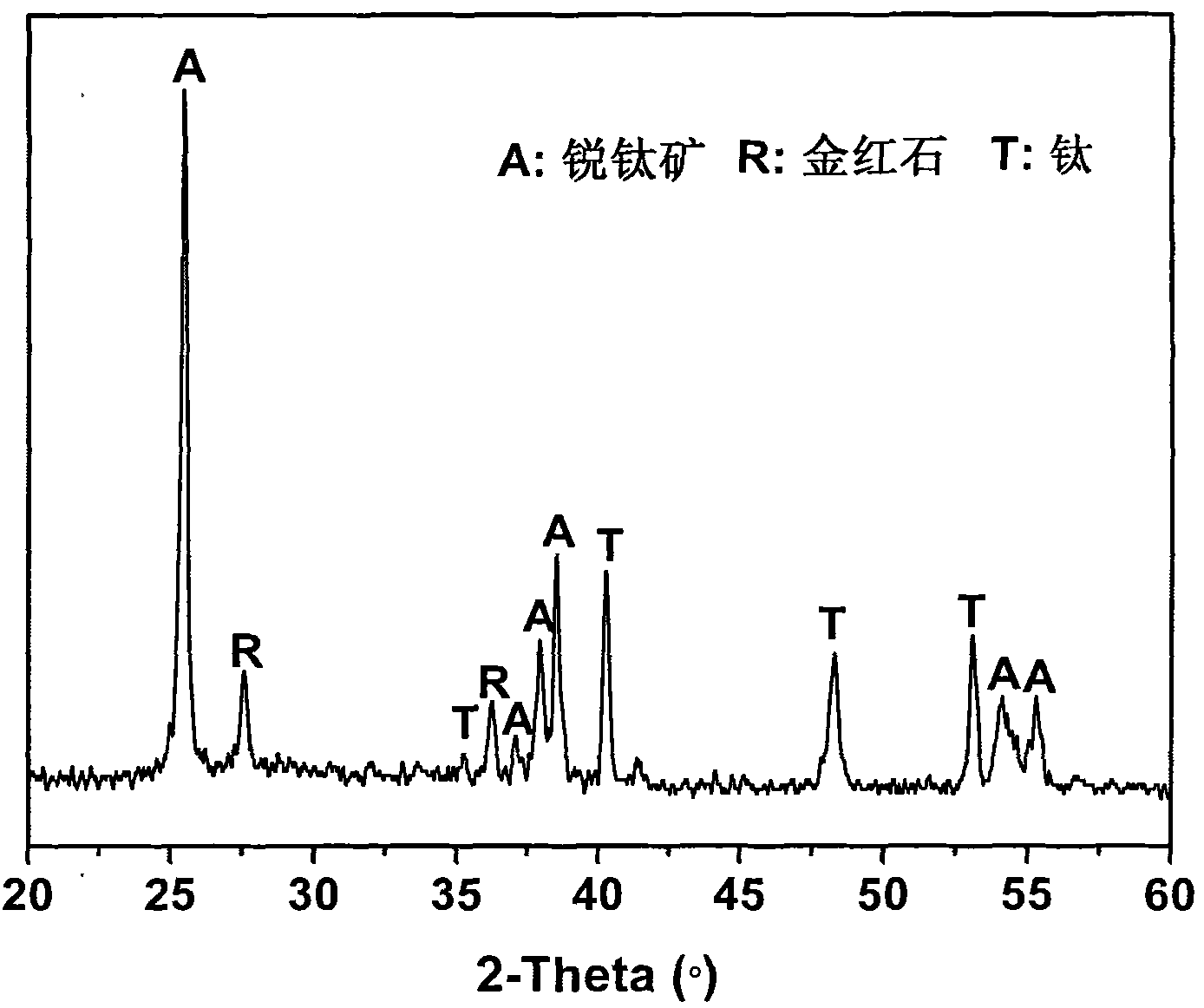

[0028] (a) Using deionized water, mix 0.04 mol / L magnesium acetate, 0.1 mol / L calcium acetate and 0.05 mol / L sodium glycerophosphate to prepare an electrolyte solution. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 0.5A / cm 2 , under the conditions of voltage 390-460V, frequency 800Hz, and duty ratio 10% for 4 minutes, and keep the electrolyte temperature below 60°C (50°C). (c) After the sample was taken out, it was rinsed in deionized water and dried naturally. After testing, the thickness of the coating is about 8-15 μm, and the element composition is mainly Ti, O, Mg, Ca and P. X-ray diffraction analysis shows that the coating phase composition is mainly pure anatase TiO 2 and rutile TiO 2 , EDS results show that the content of magnesium in the coating is about 1.3wt%, and SEM analysis shows that the pore size of the coating is less than 10 μm, and the grain size is 10-80nm.

[0029] fi...

Embodiment 2

[0031] (a) Using deionized water, mix 0.08 mol / L magnesium acetate, 0.1 mol / L sodium hydroxide, 0.1 mol / L calcium acetate and 0.05 mol / L sodium glycerophosphate to prepare an electrolyte. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 1A / cm 2 , under the conditions of voltage 400-480V, frequency 800Hz, and duty cycle 10% for 3 minutes, and keep the electrolyte temperature below 60°C (50°C). (c) After the sample was taken out, it was rinsed in deionized water and dried naturally. After testing, the thickness of the coating is about 15-25 μm, and the element composition is mainly Ti, O, Mg, Ca and P. X-ray diffraction analysis shows that the coating phase composition is mainly anatase TiO 2 and rutile TiO 2 , EDS results show that the content of zinc in the coating is about 3.2wt%, and SEM analysis shows that the pore size of the coating is less than 15 μm, and the grain size is 20-100nm.

Embodiment 3

[0033] (a) Use deionized water to mix 0.02mol / L magnesium nitrate and 0.1mol / L calcium acetate to prepare electrolyte. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 0.9A / cm 2 1. Treat for 5 minutes under the conditions of voltage 300-350V, frequency 1000Hz, and duty cycle 30%, and keep the electrolyte temperature below 60°C (40°C). (c) After the sample was taken out, it was rinsed in deionized water and dried naturally. After testing, the thickness of the coating is about 3-8 μm, and the element composition is mainly Ti, O, Mg and Ca. X-ray diffraction analysis shows that the coating phase composition is pure anatase TiO 2 , EDS results show that the magnesium content in the coating is about 0.7wt%, and SEM analysis shows that the pore size of the coating is less than 1 μm, and the grain size is 10-80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com