Wind power generation structure

A blade structure and joint technology, which is applied to wind turbines, wind turbine combinations, wind turbines at right angles to the wind direction, etc., can solve problems such as increased difficulty in recovering costs, difficulty in manufacturing spiral blades, and difficulty in promoting wind power generation, etc. Achieve the effect of not easy to manufacture, easy to promote and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

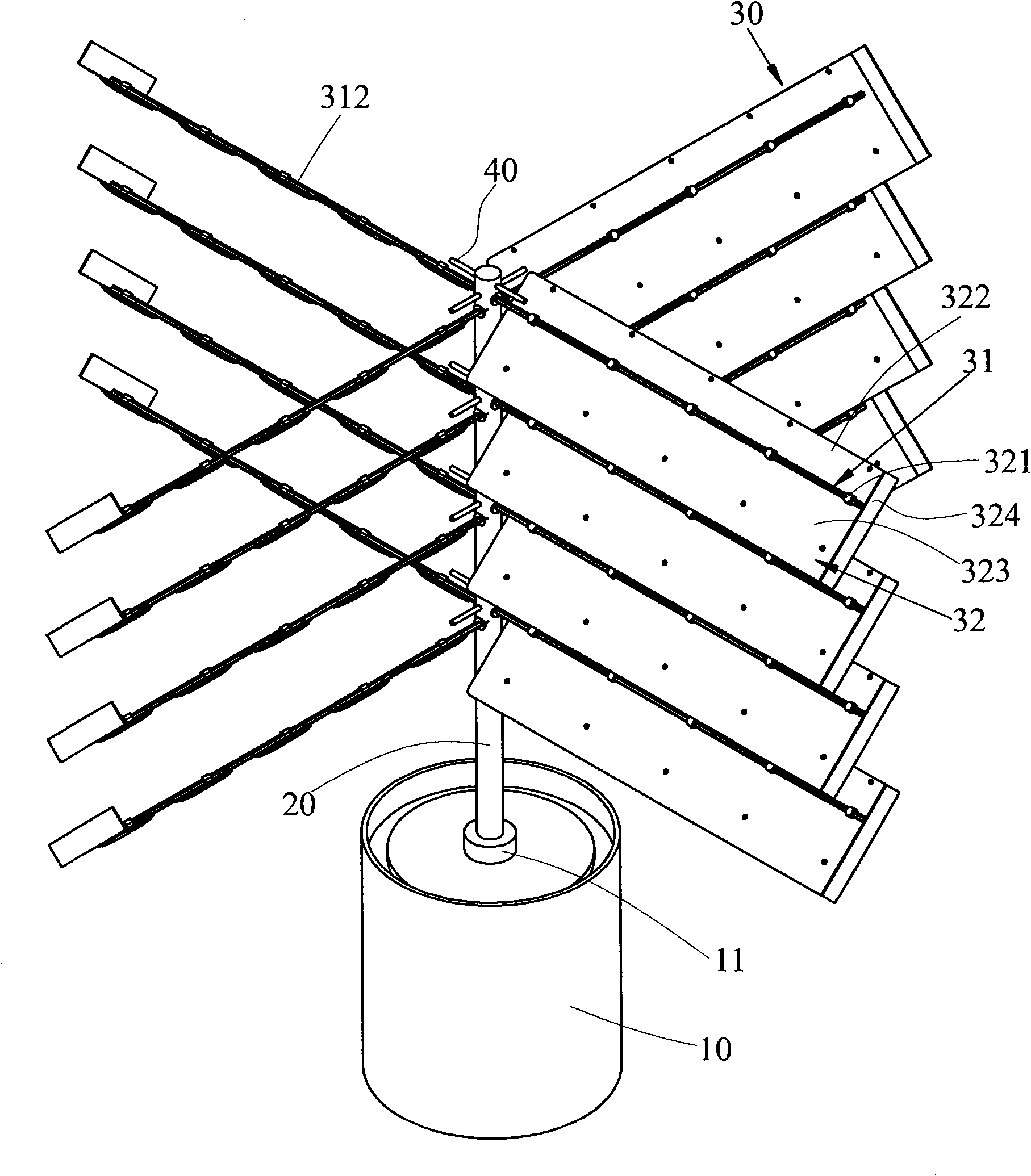

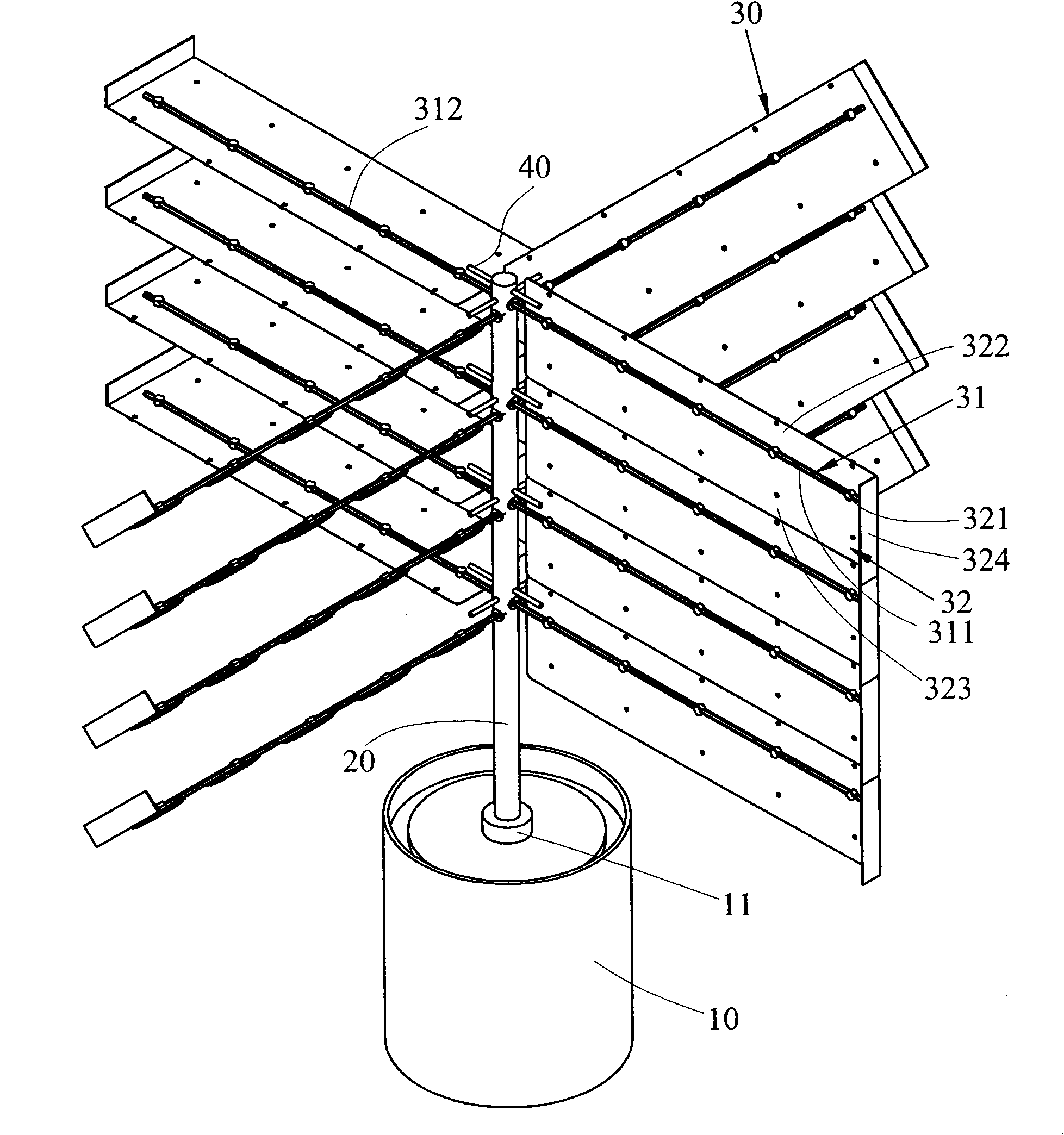

[0026] refer to Figure 1 to Figure 5 As shown, the present invention provides a wind power generation structure, comprising:

[0027] a power generation device 10;

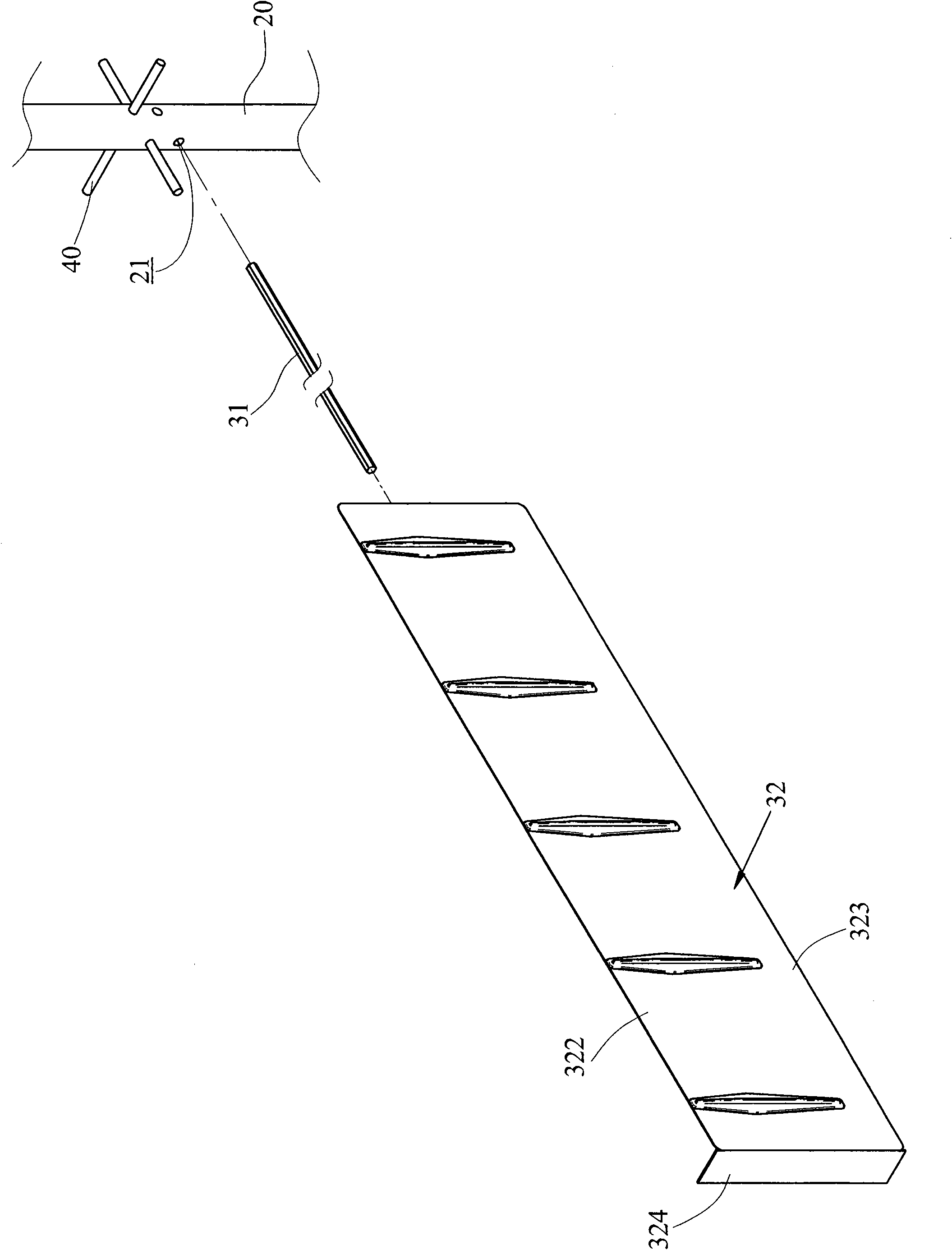

[0028] A rotating shaft 20, the rotating shaft 20 is power-connected to an input shaft 11 of the power generating equipment 10, and a plurality of transverse through holes 21 are equidistantly provided on the rotating shaft 20;

[0029] A number of blade structures 30, the blade structure 30 includes a number of connection rotation shaft 31 and a number of blades 32, the connection rotation shaft 31 is pivoted through the transverse through hole 21 of the rotation shaft 20, so that the connection on both sides of the rotation shaft 20 The rotating shaft 31 forms a first shaft end 311 and a second shaft end 312, and the first shaft end 311 and the second shaft end 312 are equal in length. There is a joint part 321, and the blade 32 is divided into an upper half part 322 and a lower half part 323 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com