Anti-oscillation interphase hardware tool for double bundle conductor

A technology for splitting conductors and sub-conductor spacers, which is applied in the field of overhead transmission lines, can solve the problems of unsuitable split sub-conductors, inability to achieve stepless adjustment, hidden dangers of construction safety, etc., and achieves wide application range, convenient installation and operation, and improved The effect of affordability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

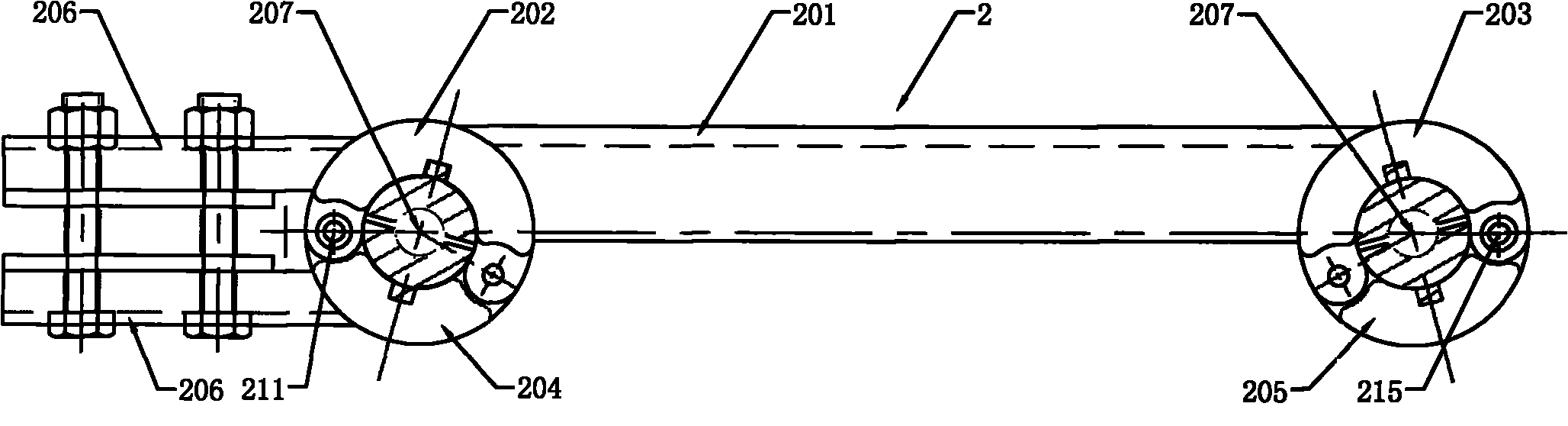

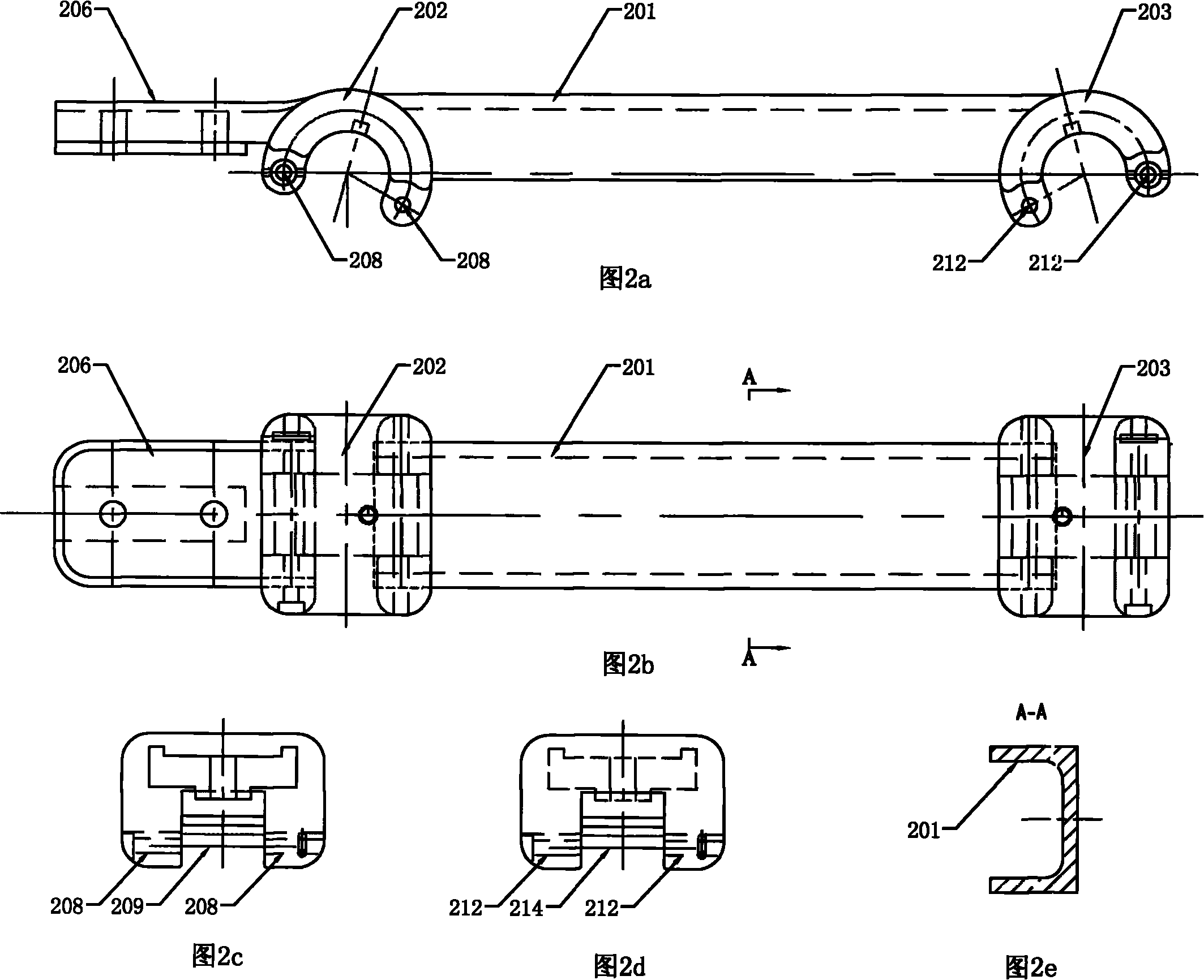

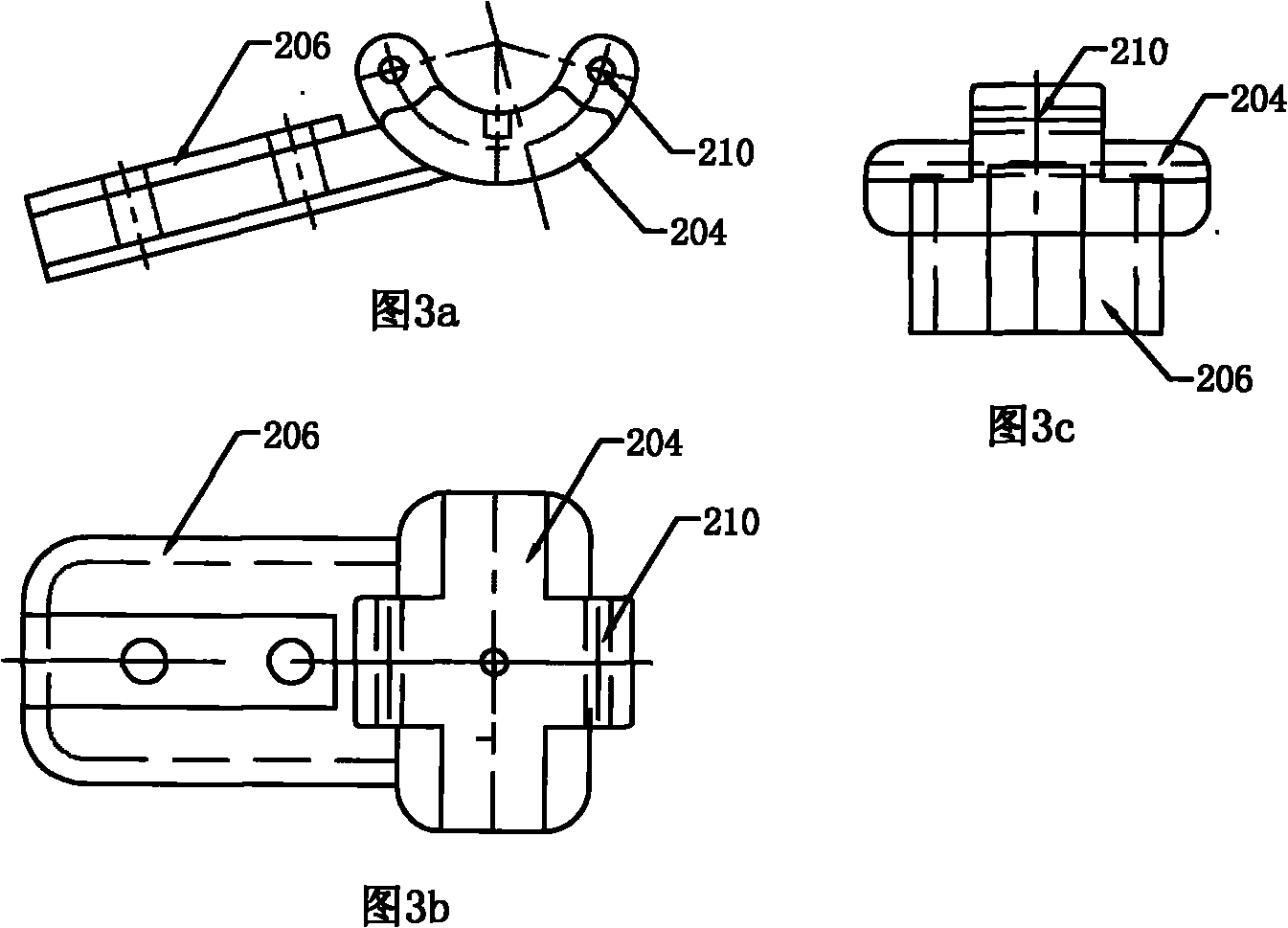

[0031] The interphase anti-galloping fittings for two split wires of the present invention will be described in further detail below with reference to the accompanying drawings.

[0032] Such as Picture 10 As shown, the interphase anti-dancing hardware in this example includes a composite insulator 1 and two sub-conductor spacers 2. The two ends of the composite insulator 1 are slot-shaped hole fittings, and a sub-conductor spacer 2 is connected to the ZBD-type hanging plate 3 The slot-shaped hole fittings at one end of the composite insulator 1 are hinged, and the other sub-conductor spacer 2 is hinged with the slot-shaped hole fittings at the other end of the composite insulator 1 through the right-angle hanging plate 4, between the right-angle hanging plate 4 and the sub-conductor spacer 2 Connect a turnbuckle screw 5. The turnbuckle screw 5 is hinged with the right-angle hanging plate 4 through the screw buckle 503 at the end of one screw 502, and hinged with the sub-wire sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com