Encapsulated hydrophobic actives via interfacial polymerization

An active ingredient, hydrophobic technology for use in personal care compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

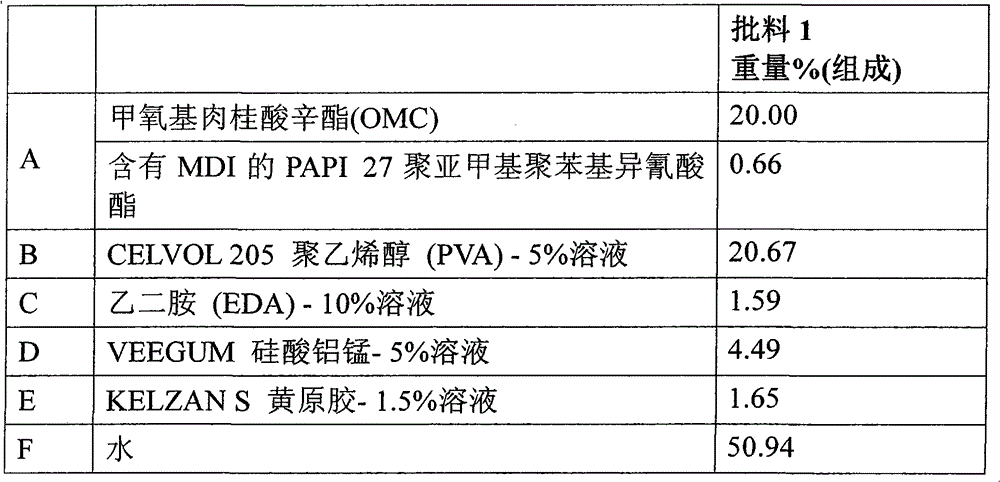

[0058] Exemplary encapsulated hydrophobic actives of the present invention contain the components described in Table 1.

[0059] Table 1

[0060]

[0061] Mix A component. For example, emulsify component B using a Silverson Model L4RTA with a 2-1 / 4 inch high shear emulsification head. Add A slowly to B while mixing eg at 1000-1500 rpm. The mixing speed is then increased until the droplet size is about 0.5 microns less than the desired final particle size, which speed is hereinafter referred to as the "desired droplet velocity". C was then added dropwise at a mixing speed ("C mixing speed") that was 1000-2000 rpm lower than the desired droplet speed. The mixing speed was then reduced again to a relatively slow speed, and the mixture was stirred for 3-4 minutes, after which the mixing speed was increased back to C mixing speed, and D, E, and F were added. Afterwards, the mixture was stirred for 3-4 minutes, the composition comprising OMC particles encapsulated by an inte...

Embodiment 2

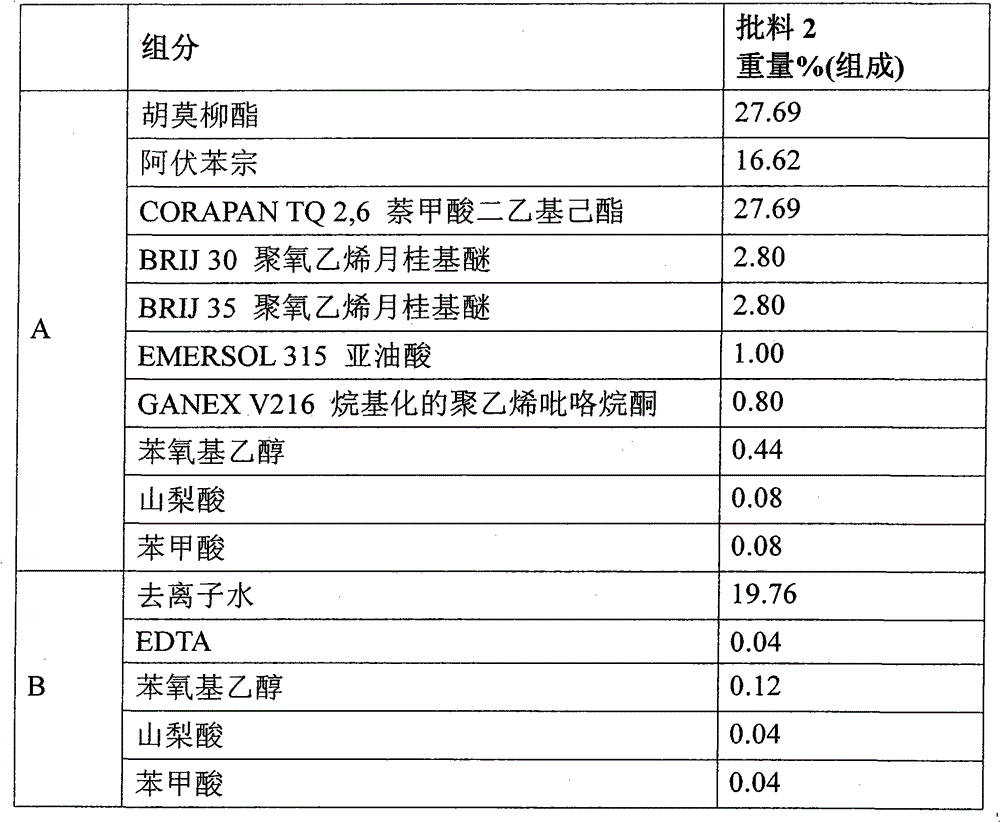

[0063] Exemplary sunscreen bases contain the components described in Table 2.

[0064] Table 2

[0065]

[0066] Combine A and place in an oven at about 80°C until the solid ingredients have dissolved. A was then removed from the oven and cooled to below about 40°C. B is combined, then A and B are combined, preferably homogenized, eg by using an IKA mixer.

Embodiment 3

[0068] Formulations prepared essentially according to the above protocol in Examples 1 and 2 were prepared and combined with comparative components as in Table 3 to provide sunscreen compositions:

[0069] table 3

[0070] Batch 3 (comparison) Batch 4 Batch 1 -- 31% DDS 621 emulsified OMC 9.55% -- Batch 2 18.05% 18.05% CARBOPOL 940 carboxyvinyl polymer 0.2% 0.2% water 72.2% 50.75%

[0071] The order of addition was: base sunscreen (batch 2) mixed with batch 1 or DDS 621 emulsified OMC (Dow Chemical Company) and CARBOPOL polymer, then mixed with water.

[0072] For 10 panelists, 0.05 g of each sample was applied to designated areas on their right or left forearm. Initially, each sample was evaluated for spreadability, absorption to the skin, smoothness, stickiness, greasiness, moist feel, and overall skin feel, and then re-evaluated 1 hour later for moist feel, oiliness, skin smoothness, and skin feel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com