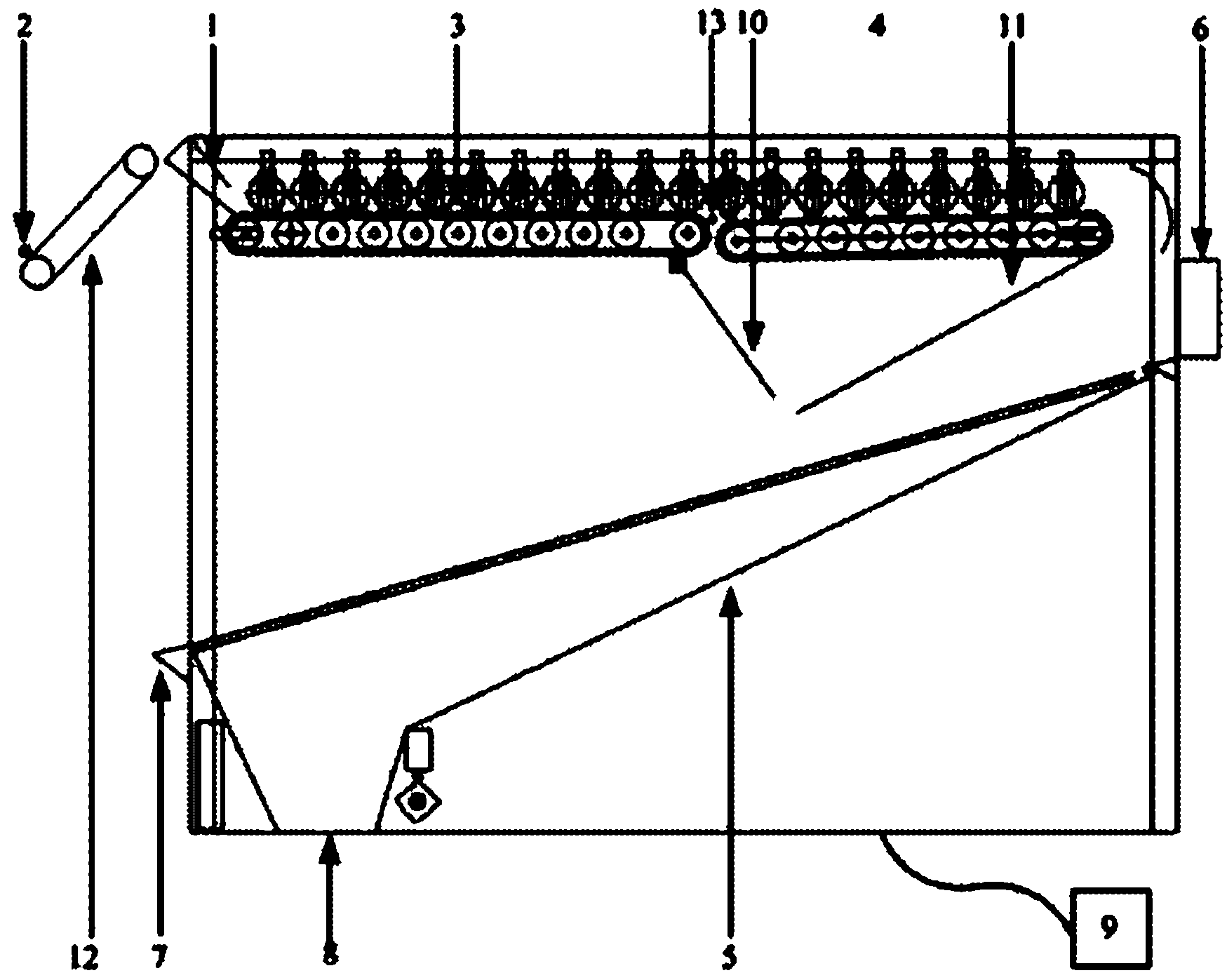

Full-automatic grain separation system for high-accuracy single plant inspection

A separation system, high-precision technology, applied in applications, threshing equipment, agricultural machinery and implements, etc., to achieve the effect of good adaptability, good threshing effect, and low operating failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

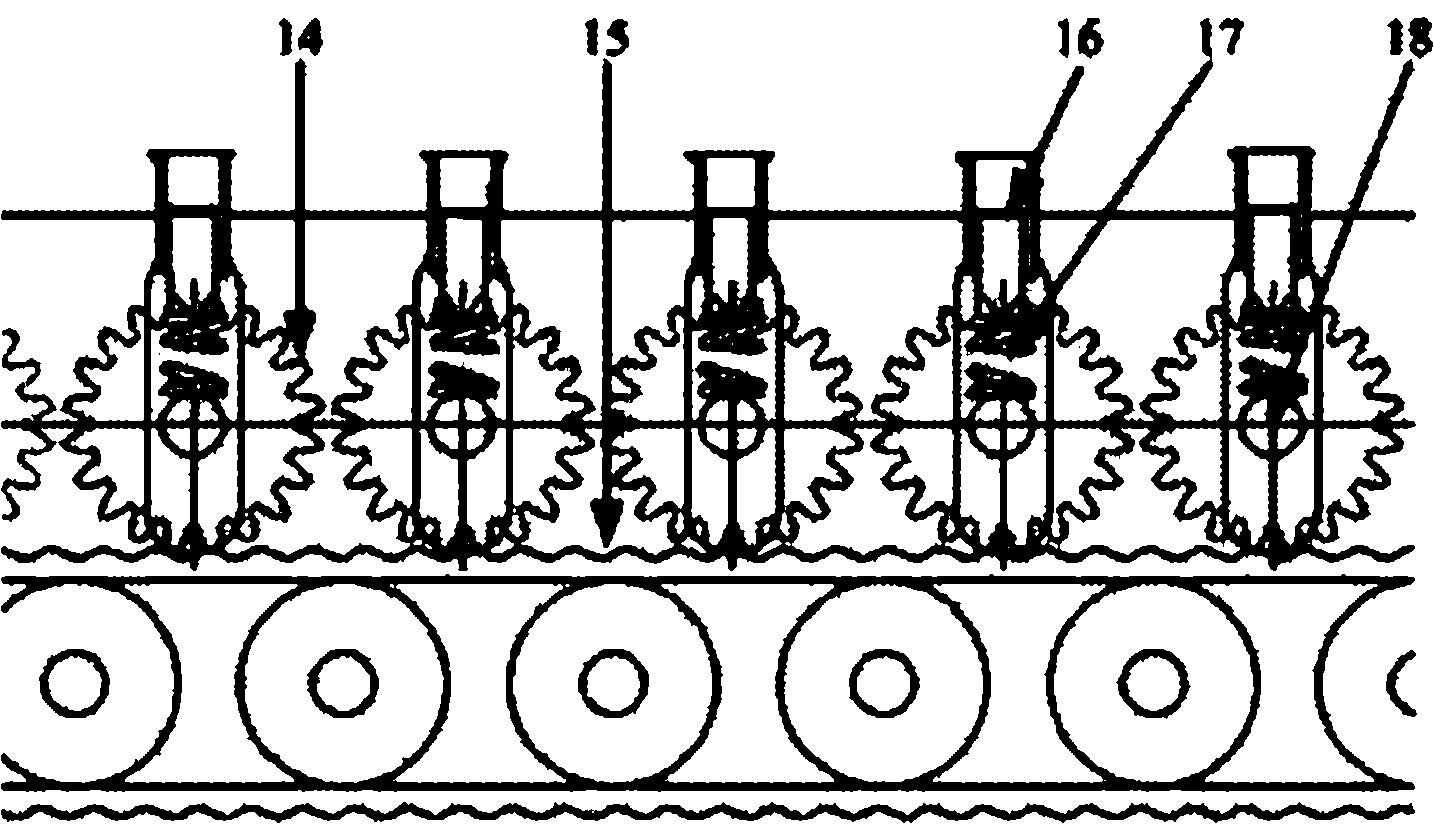

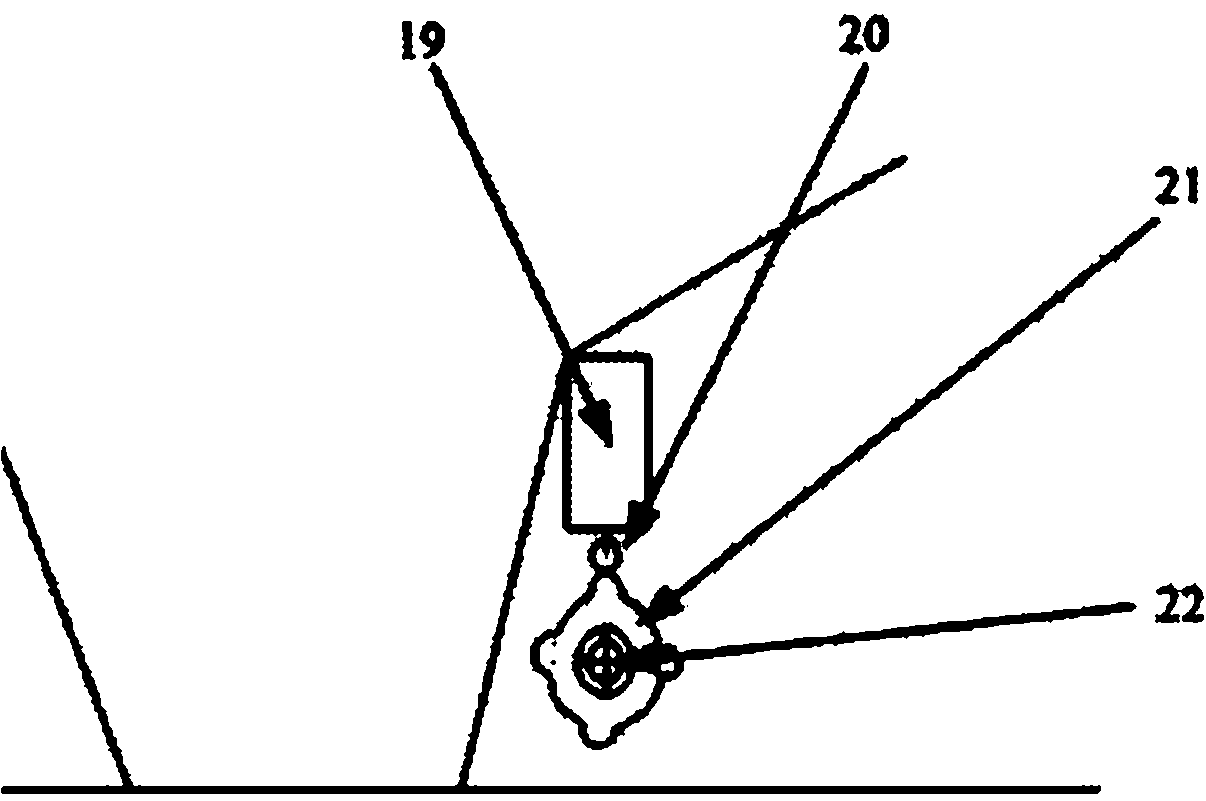

Method used

Image

Examples

Embodiment

[0022] Experimental biological material: 10 mature ears of rice;

[0023] Firstly, 10 cut ears of rice are dried and pretreated under normal sunlight, and then each ear of each plant is placed one by one on the rice ear lifting conveyor line of the automatic grain separation system for automatic grain separation, and the ears are collected separately. Impurity at the rod outlet and grain at the grain outlet. The grain threshing error of the system can be analyzed by analyzing the grains collected through the outlet of each ear stalk and the grain outlet. The following are the results of the system test:

[0024] Table 1 Test results

[0025]

[0026] From the test results, we analyze the error of the system, as shown in Table 2:

[0027] Table 2 Error Analysis

[0028]

[0029] Among them, the calculation formula of each error parameter is as follows:

[0030]

[0031]

[0032]

[0033]

[0034]

[0035]

[0036]

[0037] From the error analysis, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com