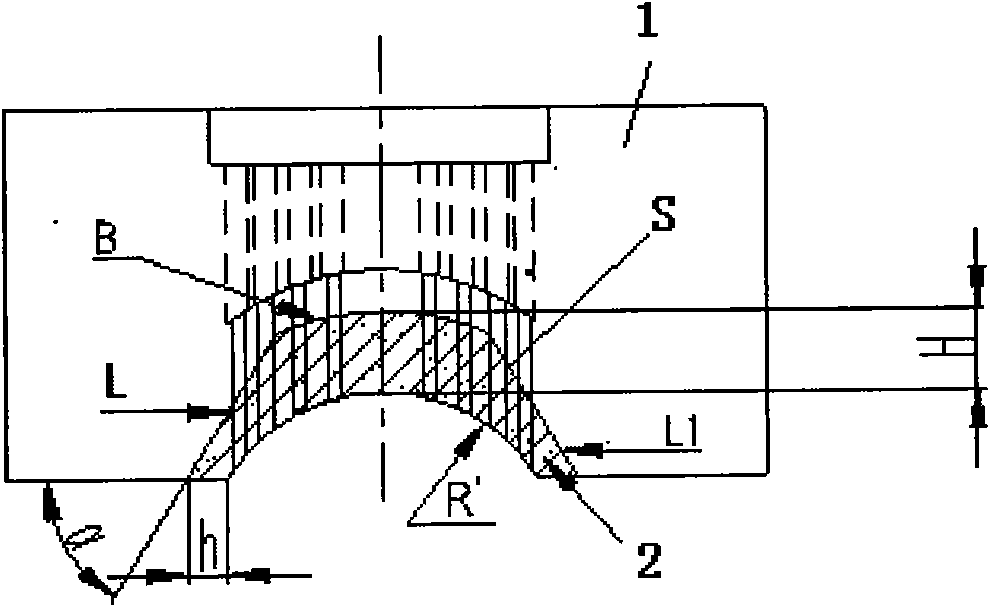

Magnetic circuit structure of high-central-field magnetic shoe mould

A high-center, center-field technology, applied in the field of magnetic circuit structure of molds, can solve problems such as large influence relationship of orientation, unsatisfactory motor operation characteristics such as torque and noise, unsatisfactory surface magnetic field strength and center field, etc. To achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

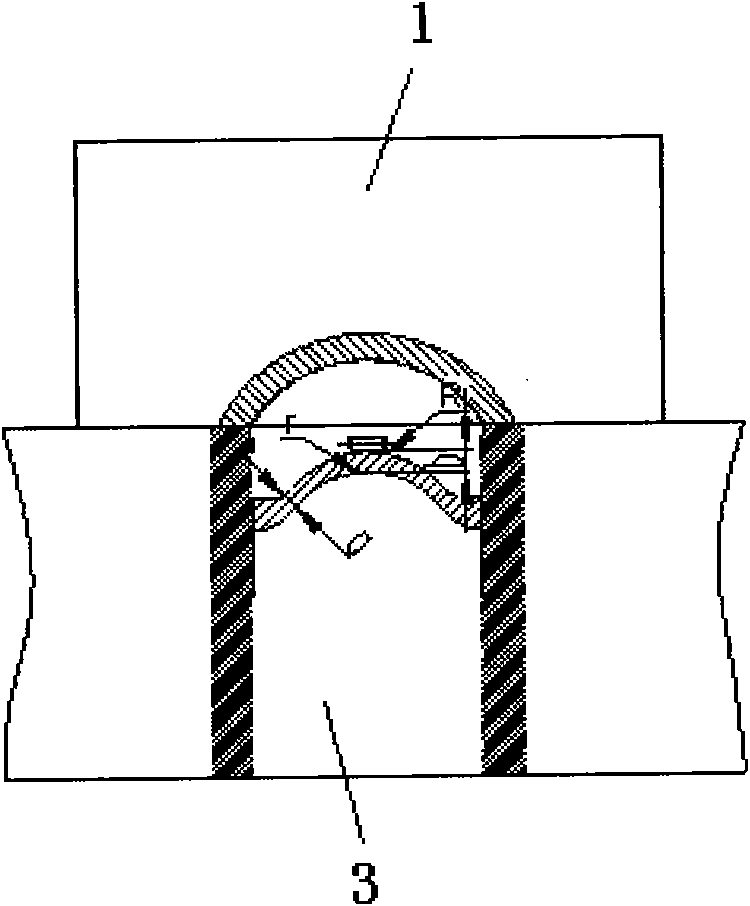

Examples

Embodiment 1

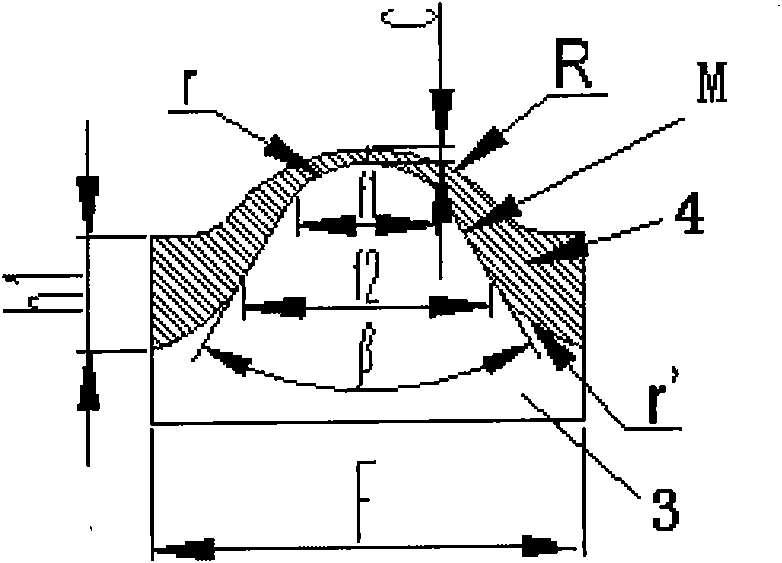

[0047] The product specification selected in this embodiment is a permanent magnet ferrite tile-type magnet for a micro-motor. The internal code of the product is W-284. For the specification and shape, see Figure 5 , where T is the placement point of the Hall probe when measuring the surface magnetic field strength.

[0048] Forming uses a slurry with a grinding particle size of 0.85. The main properties of the material: the residual magnetism is greater than 3950 Gauss, and the intrinsic coercive force is greater than 3850 Oersted.

[0049] The measurement and comparison results of the final product are shown in Table 1

[0050] Measurement items: inner arc median surface magnetic field strength and center field strength.

[0051] Apparatus used: WT-3A digital millitesla meter produced by Nanjing University Hengtong Technology Development Company.

[0052] Table 1

[0053]

[0054] It can be seen from the comparative data in Table 1 that the effect of the new magneti...

Embodiment 2

[0056] This example uses the same material as the previous example, and the product specification is R16.9*r12*W30*L37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com