Pressure feedback scraper module

A feedback type, pressure technology, applied in rotary printing presses, printing, printing presses, etc., can solve the problems of poor contact, uneven force, no depth detection and compensation design of the squeegee blade, and achieve good printing. Quality, the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to have a further understanding of the purpose of the present invention, structural features and functions thereof, the detailed description of the relevant embodiments and accompanying drawings is as follows:

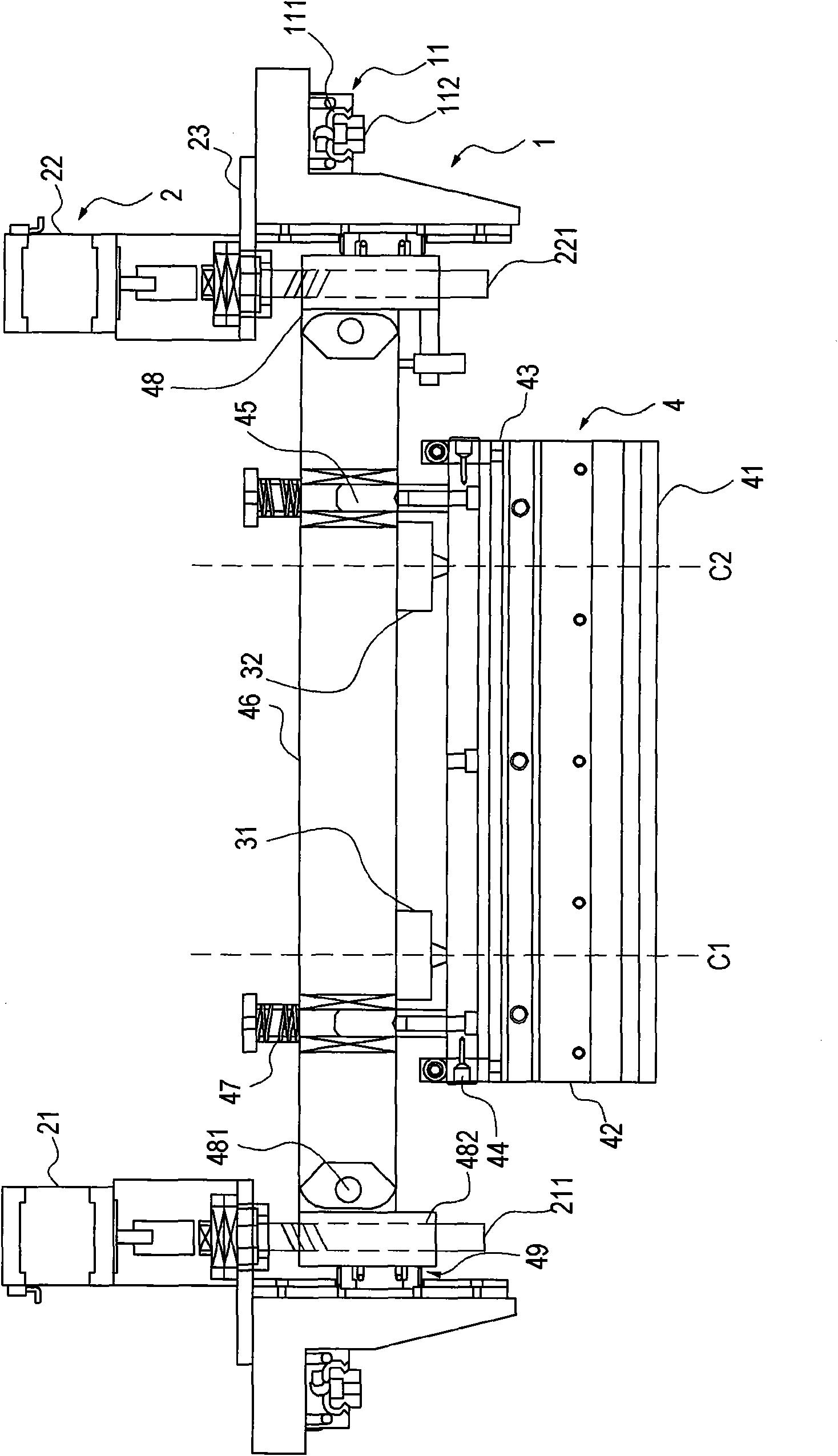

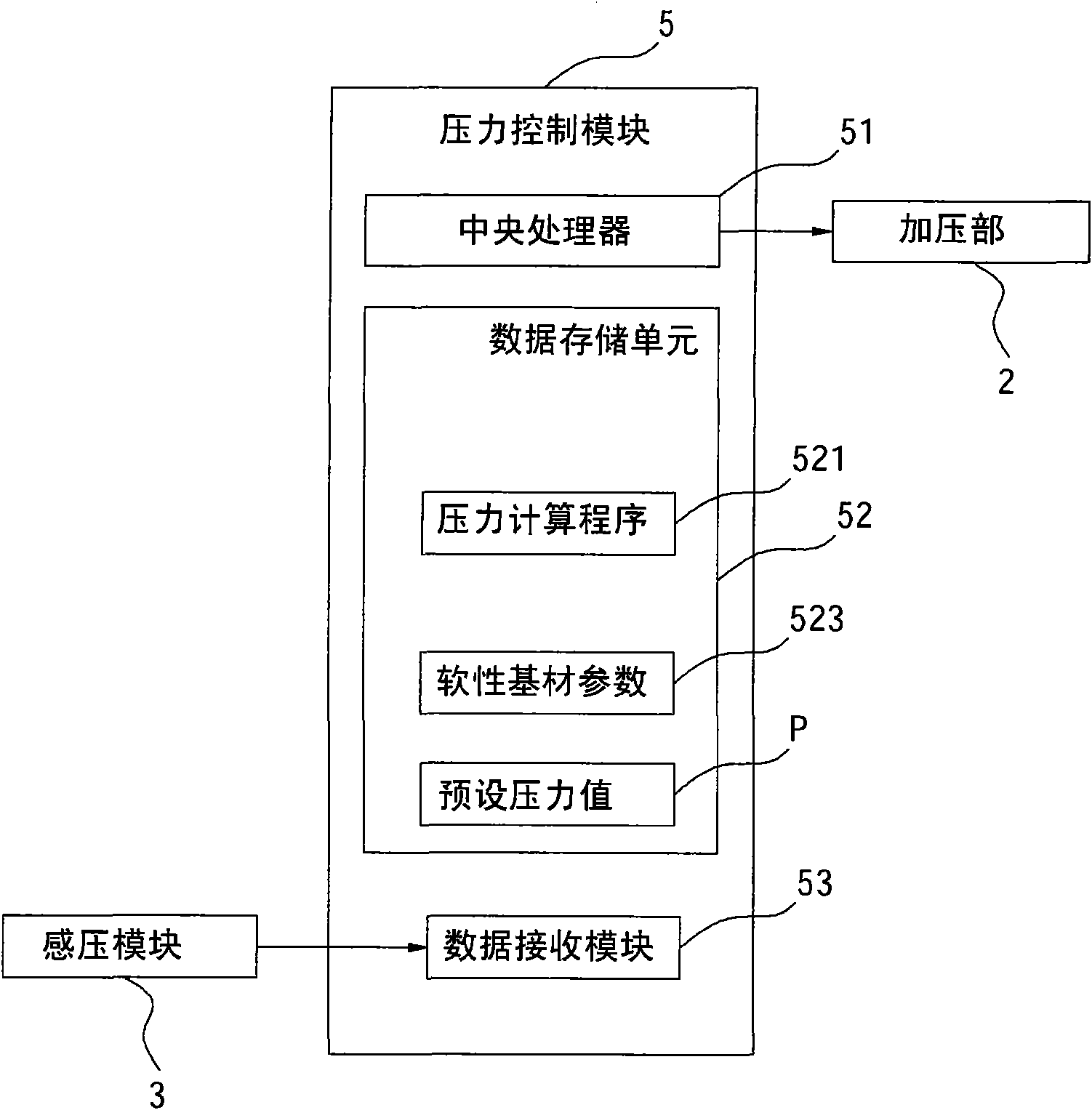

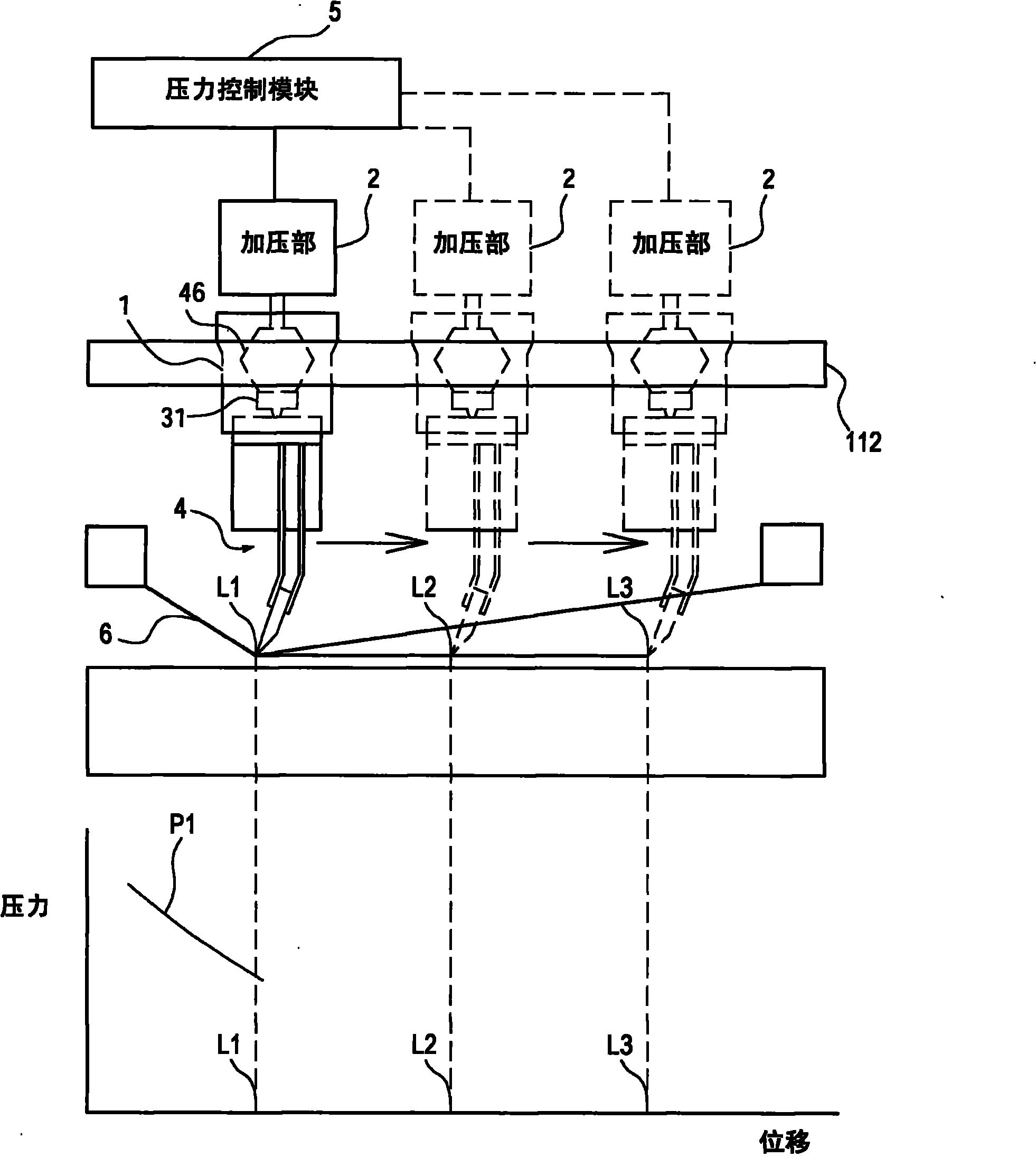

[0069] Please also refer to figure 1 , figure 2 , image 3 and Figure 4 , figure 1 It is a schematic diagram of the first structure of the scraper module according to the embodiment of the present invention, figure 2 It is an example of the structure of the pressure control module 5 of the embodiment of the present invention, image 3 For the embodiment of the present invention is figure 1 a side view taken along the first section line C1, Figure 4 For the embodiment of the present invention is figure 1 A side view taken along the second section line C2. In this embodiment, the entire scraper module includes a sliding frame 1 , a pressurizing part 2 , a pressure sensing module 3 , a pressure control module 5 and a scraper seat 4 .

[0070] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com