Fabrication process of antique imitation art decorative material

A decorative material and manufacturing process technology, applied in decorative art, decorative structure, covering/lining, etc., can solve the problems of complex manufacturing process, labor-intensive, easy to breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

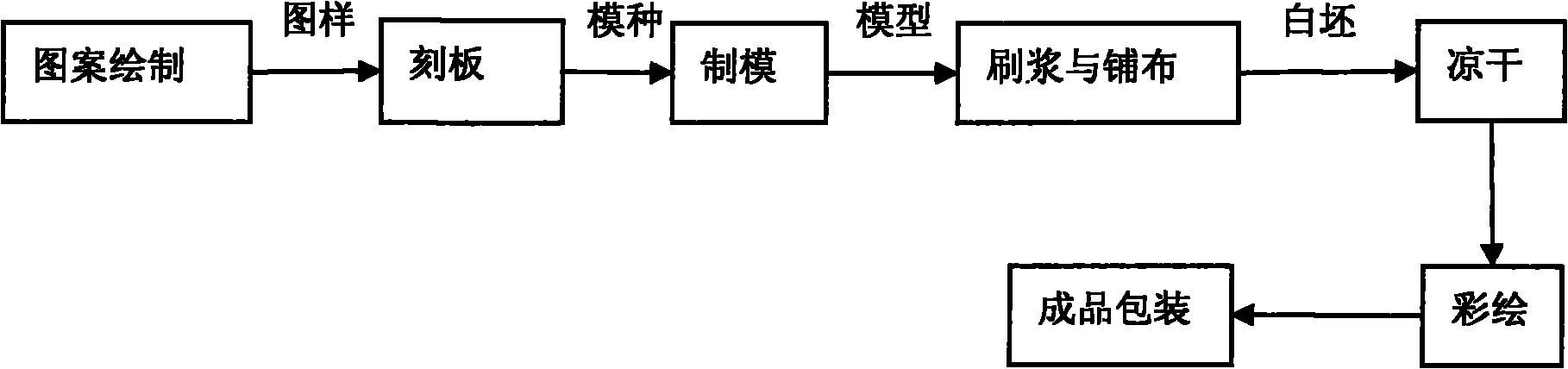

[0007] From the block diagram of the production process of this kind of antique art decoration material, we can see that the first step is pattern drawing. Draw them separately to get the pattern. The second step is stereotyping, which needs to be stereotyped according to the pattern to form a model. The third step is to make a mold. It is necessary to remake a silicone counter-mold on the model, so as to obtain the model of this pattern. The fourth step is Brushing and spreading, after having a model, you can start brushing and spreading directly in the model. It is required that the glass fiber cloth should be spread evenly, and the working procedure should be in place in one step, and the white blank of the product will be produced in this way. The fifth step is to dry in air. Place the blank for three to five days to dry naturally. The sixth step is painting. After the white blank is completely dry, it can be painted and painted. According to the requirements or design ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com