Frock black vat dye with high fastness to chlorine bleaching and hot pressing

A chlorine bleach-resistant and high-heat-resistance technology, applied in the field of black dyes, can solve the problems of darkening of color, blackening of cloth, difficulty in meeting the requirements of various indicators, etc., and achieve the effect of high lifting rate and high blackness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

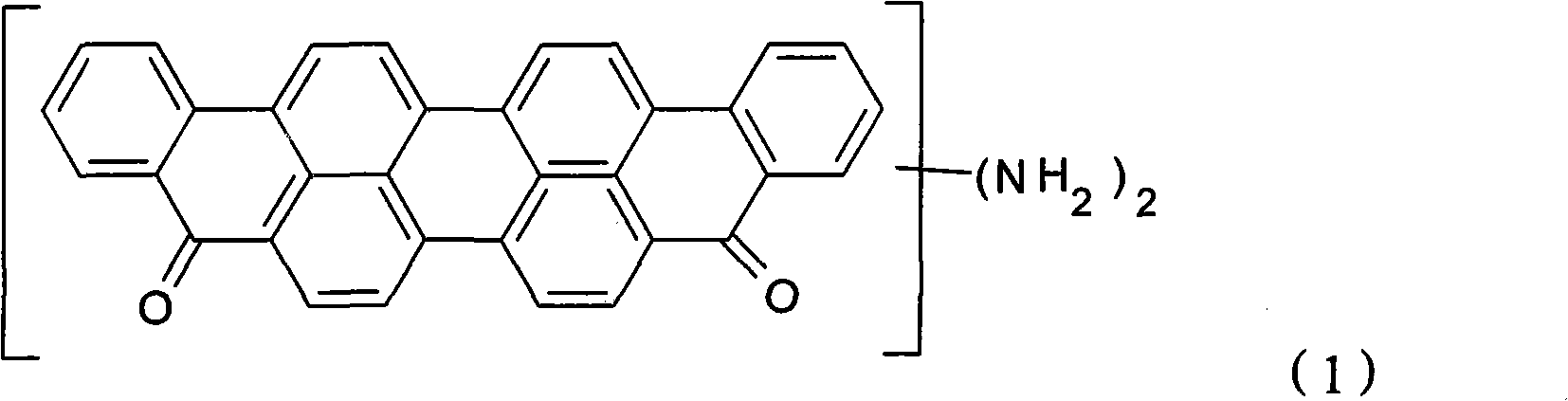

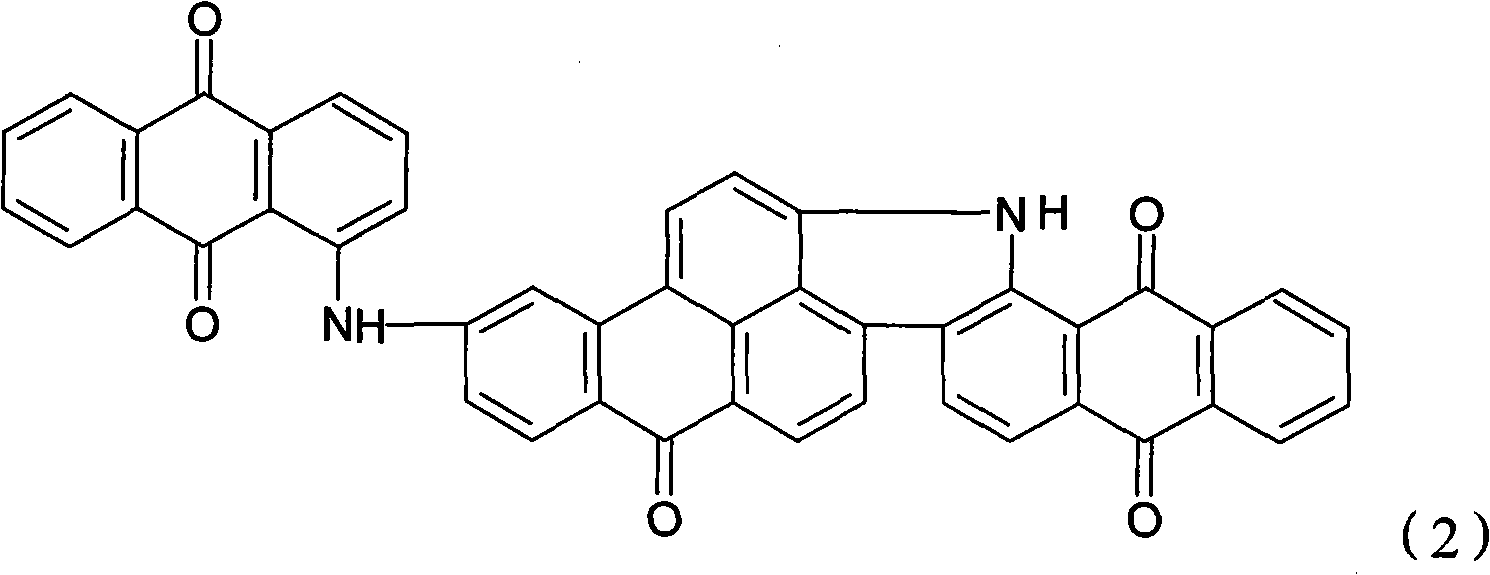

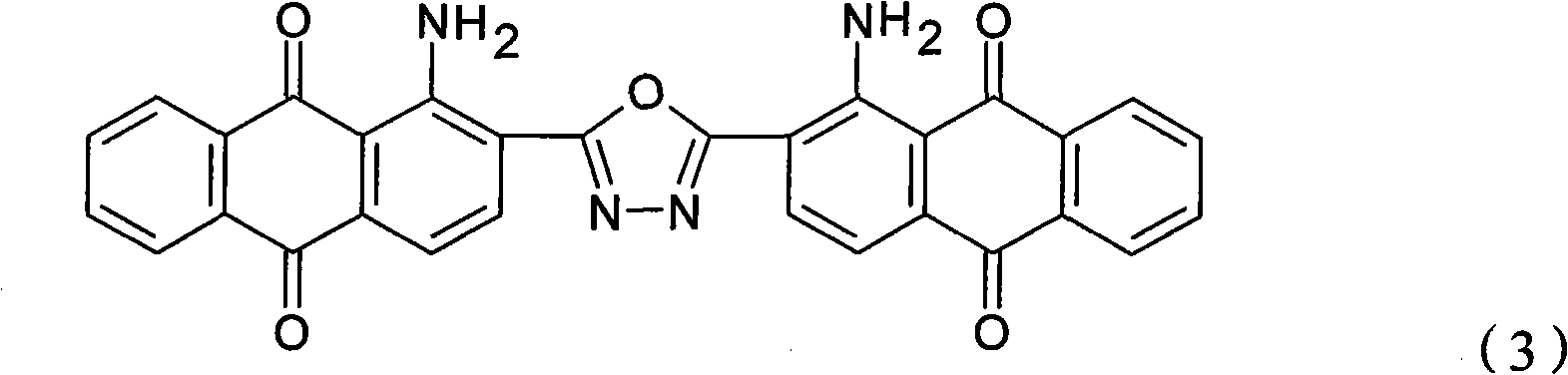

Method used

Image

Examples

Embodiment 1-5

[0023] According to the data shown in Table 1, after beating the filter cake and dispersant of vat dye monomer A, vat dye monomer B, vat dye monomer C and vat dye monomer D in metering ratio, use wet crushing technology to pulverize and grind After grinding for 72 hours, it is sent to the spray drying tower through the pipeline for drying. At the same time, it is sprayed with the amount of anti-dust oil shown in Table 1, and finally the finished product is packaged.

[0024] Table 1

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com