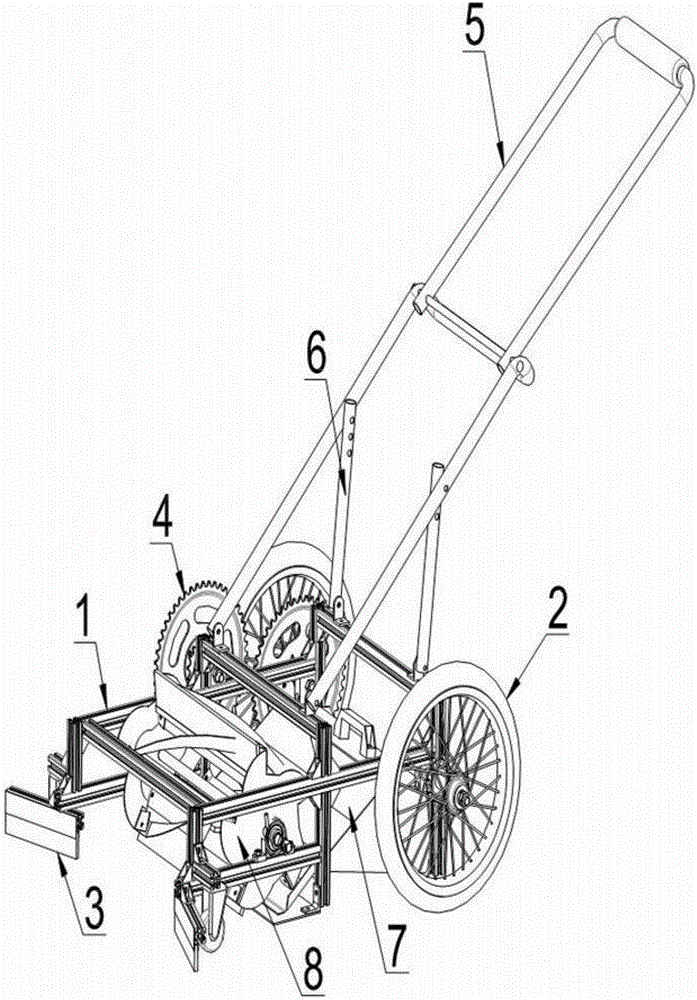

Highway vegetation afforestation weeding and sanitation device and working method thereof

A vegetation and road technology, applied in the direction of cutters, agricultural machinery and tools, applications, etc., can solve the problems of complex control procedures, large footprint, high risk factor, etc., and achieve high weeding efficiency, reasonable and compact device structure, and integration high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

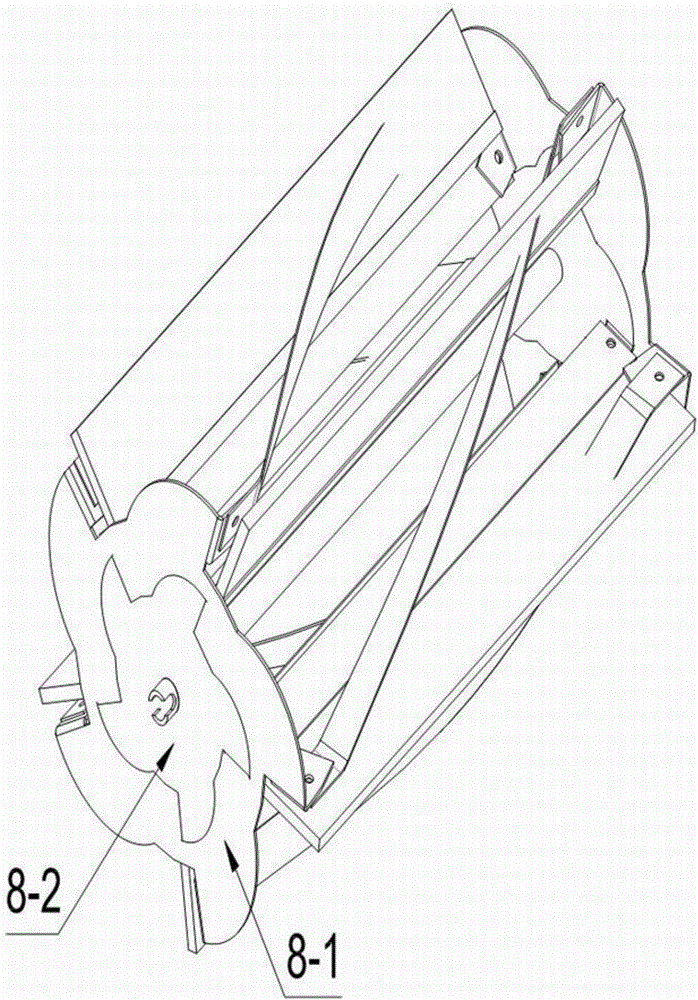

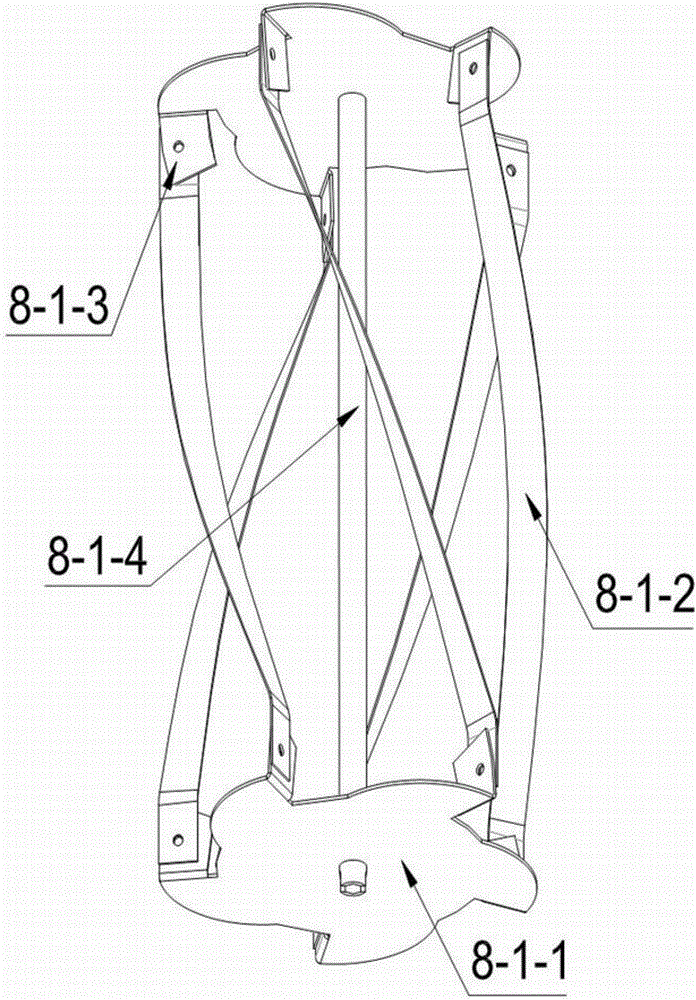

[0046] Manufacture cutting blade 8-1-2 of the present invention according to the following steps, and by weight fraction:

[0047] Step 1: Add 566 parts of ultrapure water with a conductivity of 0.66μS / cm into the reactor, start the stirrer in the reactor at a speed of 106rpm, start the heating pump, and raise the temperature in the reactor to 76°C; 76 parts of 3-(3,5-dibromo-4-hydroxyphenyl)-2-hydroxypropionic acid methyl ester, 96 parts of 4-hydroxy-α-methylphenylpropanol, 3,5-bis(1,1 - 166 parts of dimethylethyl)-4-hydroxyphenylpropionic acid methyl ester, stir until completely dissolved, adjust the pH value to 6.6, adjust the stirrer speed to 166rpm, the temperature is 106 ° C ~ 176 ° C, the esterification reaction is 26 Hour;

[0048] Step 2: Take 96 parts of N-isopropylnortropine α-(hydroxymethyl)phenylacetate, 86 parts of methyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate 166 parts of 2-methoxycarbonyl-3-(4-hydroxyphenyl) methyl propionate were added and mixed eve...

Embodiment 2

[0053] Manufacture cutting blade 8-1-2 of the present invention according to the following steps, and by weight fraction:

[0054] Step 1: Add 1516 parts of ultrapure water with a conductivity of 0.86μS / cm into the reactor, start the stirrer in the reactor at a speed of 266rpm, start the heating pump, and raise the temperature in the reactor to 96°C; 166 parts of 3-(3,5-dibromo-4-hydroxyphenyl)-2-hydroxypropionic acid methyl ester, 166 parts of 4-hydroxy-α-methylphenylpropanol, 3,5-bis(1,1 - 356 parts of dimethylethyl)-4-hydroxyphenylpropionic acid methyl ester, stir until completely dissolved, adjust the pH value to 8.6, adjust the stirrer speed to 266rpm, the temperature is 176°C, and the esterification reaction is 36 hours;

[0055] Step 2: Take 206 parts of N-isopropylnortropine α-(hydroxymethyl)phenylacetate, 166 parts of methyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate 356 parts of methyl 2-methoxycarbonyl-3-(4-hydroxyphenyl) propionate were added and mixed evenly...

Embodiment 3

[0060] Manufacture cutting blade 8-1-2 of the present invention according to the following steps, and by weight fraction:

[0061] Step 1: Add 916 parts of ultrapure water with a conductivity of 0.76μS / cm into the reactor, start the stirrer in the reactor at a speed of 166rpm, start the heating pump, and increase the temperature in the reactor to 86°C; 116 parts of 3-(3,5-dibromo-4-hydroxyphenyl)-2-hydroxypropionic acid methyl ester, 136 parts of 4-hydroxy-α-methylphenylpropanol, 3,5-bis(1,1 -256 parts of dimethylethyl)-4-hydroxyphenylpropionic acid methyl ester, stirred until completely dissolved, adjusted the pH value to 7.6, adjusted the stirrer speed to 206rpm, the temperature was 136°C, and the esterification reaction was carried out for 33 hours;

[0062] Step 2: Take 126 parts of N-isopropylnortropine α-(hydroxymethyl)phenylacetate, 136 parts of methyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate 256 parts of methyl 2-methoxycarbonyl-3-(4-hydroxyphenyl) propionate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com