Multi-functional double-acting hydraulic oil extraction device

An oil production device and double-acting technology, which is applied in the direction of production fluid, earth drilling, liquid displacement machinery, etc., can solve the problems affecting the stability of the hydraulic system, the wear of the plunger and the pump barrel, and the impact on the working efficiency, etc. Force balance, high thrust force, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

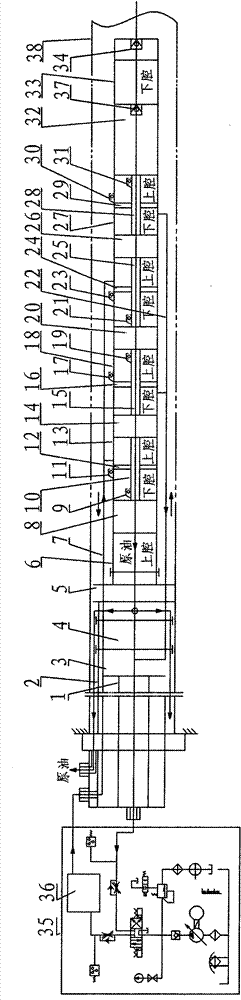

[0029] The present invention will now be described in further detail in conjunction with the accompanying drawings and specific embodiments.

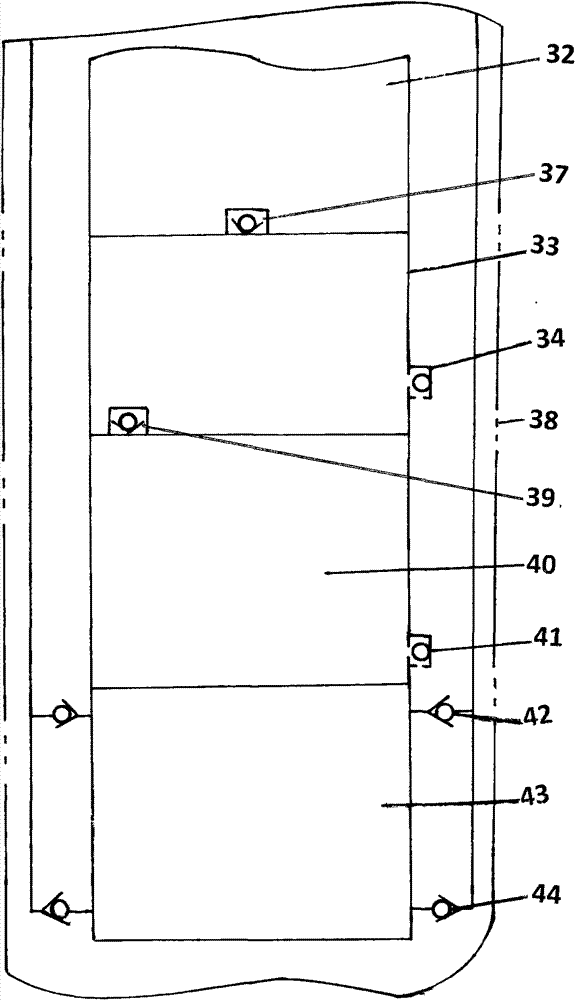

[0030] Such as figure 1 As shown, the two-way oil well pump 18 of this multifunctional double-acting hydraulic oil production device is placed in the casing 38 under the oil well, and the two-way oil well pump barrel 18 is provided with a long plunger 20, and a hollow pull rod is arranged on the long plunger 20 15 and 25, a piston 14 is set on the hollow tie rod 15, a piston 26 is set on the hollow tie rod 25, the pistons 14 and 26 are respectively set on the hydraulic cylinders 13 and 27, and the two-way oil pump barrel 18 is set on the hydraulic cylinders 13 and 27 Between them, floating oil outlet valves 19 and 21 are respectively arranged on the hollow tie rods 15 and 25, and fixed oil inlet valves 17 and 23 are respectively arranged under and above the sealing end caps 16 and 24, and the hydraulic cylinders 13 and 27 respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com