Unidirectional pulley for AC generator

An alternator and pulley technology, applied in the direction of belt/chain/gear, one-way clutch, mechanical equipment, etc., can solve the complex manufacturing process of the first flange of the hub, cannot eliminate the alternator resonance, and has a long response time interval and other problems, to achieve the effect of simple manufacturing process, simple structure and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

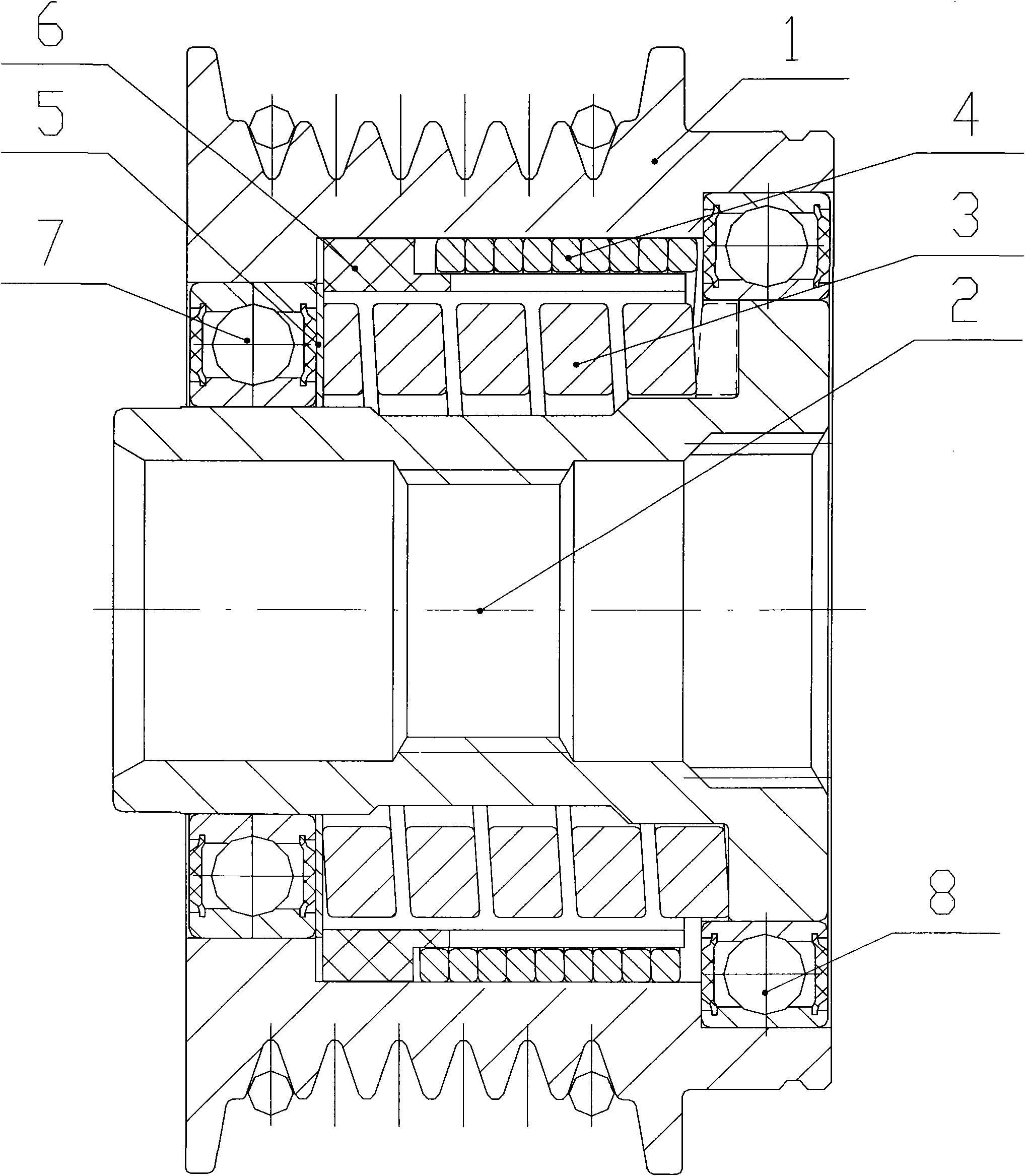

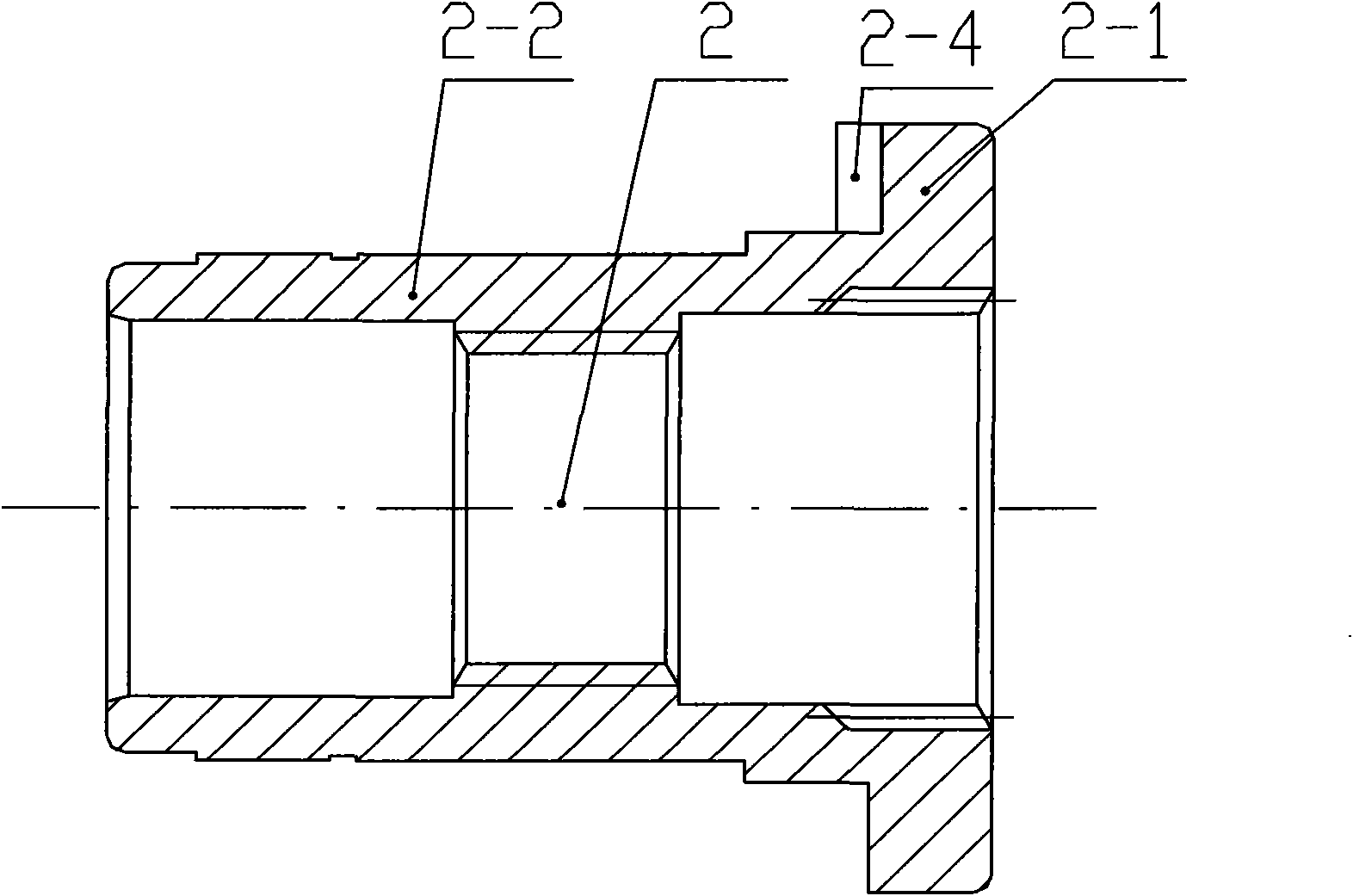

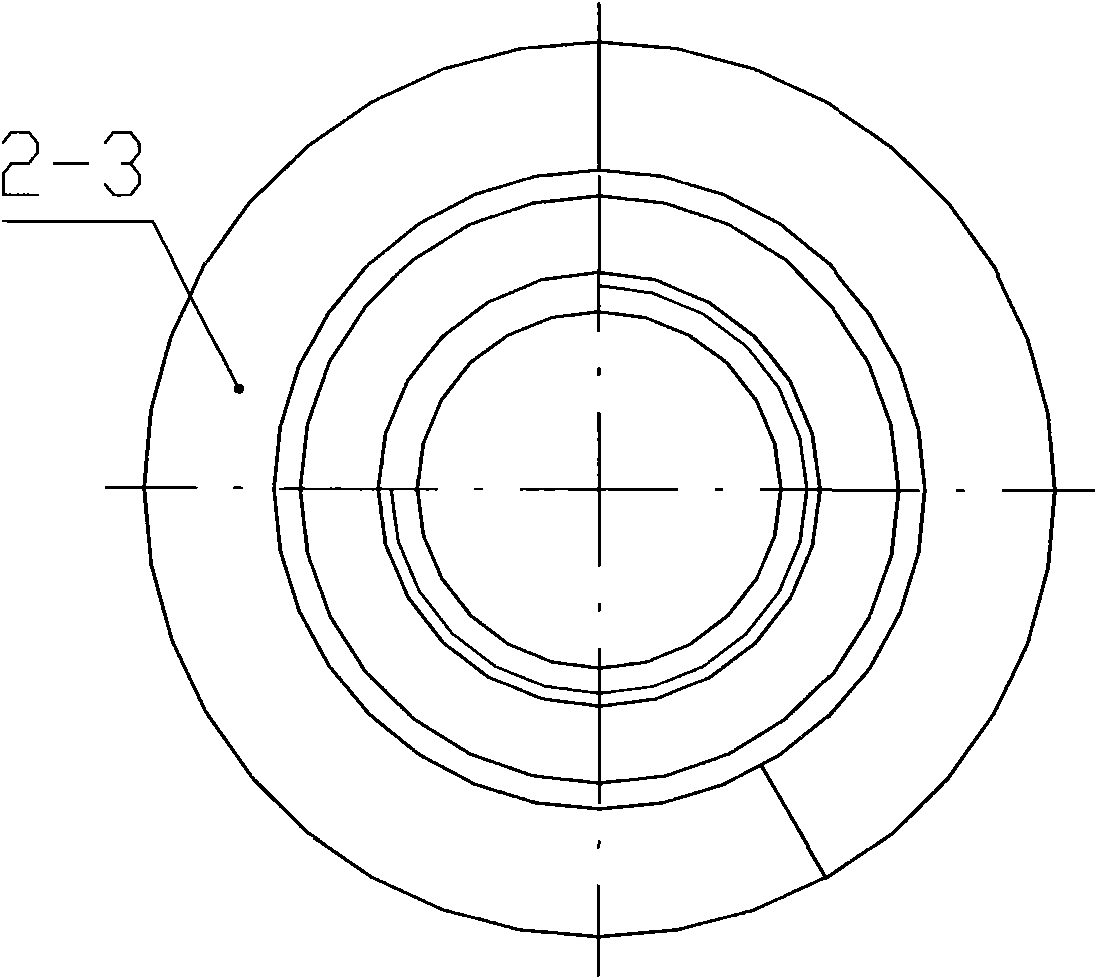

[0024] Such as Figure 1-12 The shown specific embodiment of the one-way pulley for an alternator of the present invention has a pulley 1, a mandrel 2, a torsion spring 3, a friction spring 4, a thrust washer 5 and a cage 6, and the cage 6 is made of plastic , the cage 6 is composed of a roughly annular end portion 6-1 and a tubular spacer portion 6-2, the spacer portion 6-2 has ten shafts uniformly distributed around the circumference for eliminating the resonance generated by the pulley To the long groove 6-2-1; the friction spring 4 is wound on the spacer part 6-2 of the cage, and the torsion spring 3 is set on the mandrel 2 and located in the spacer part 6-2 of the cage 6.

[0025] The friction spring 4 includes a bending part 4-1 and a coil 4-2, and the bending part 4-1 of the friction spring 4 is composed of an axial bending 4-1-1, a circumferential bending 4-1-3 and a radial bending Composed of folding 4-1-2, the axial bending 4-1-1 is connected with the coil 4-2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com