Tail low-resistance heat exchange device for micro-positive pressure oil and gas fired boiler

A gas-fired boiler and heat exchange device technology, applied in liquid degassing, fluid heaters, lighting and heating equipment, etc., can solve the problem of large resistance and inability to continuously meet the combustion characteristics of micro-positive pressure boilers, heat transfer efficiency, that is, heat transfer coefficient Failure to meet the design requirements and other problems, to achieve the effect of reducing smoke resistance, avoiding unsafe factors, and ensuring continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

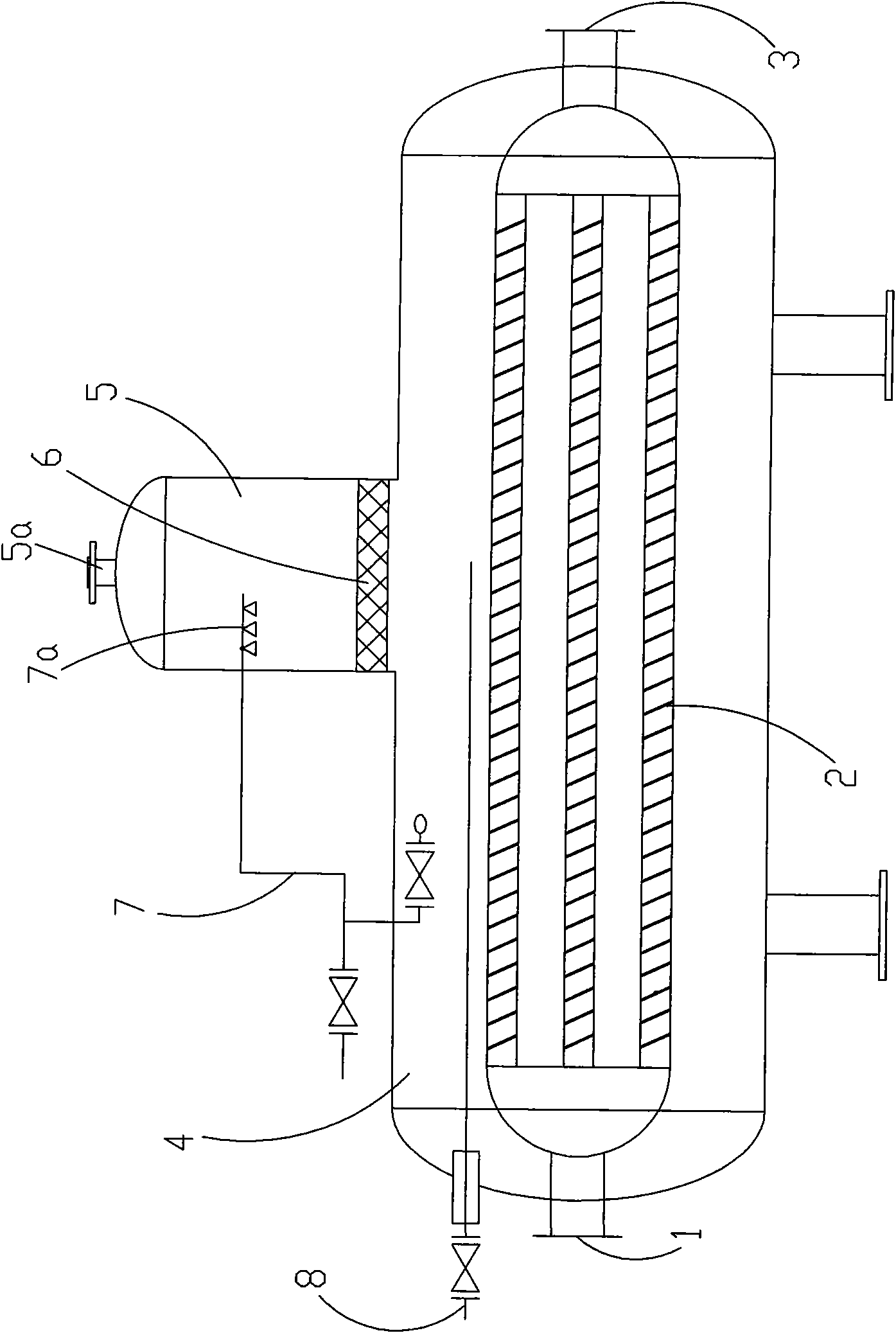

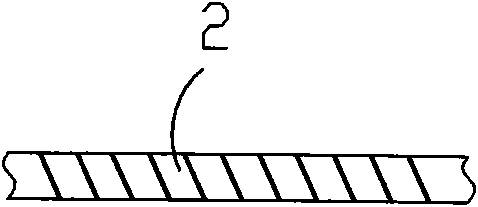

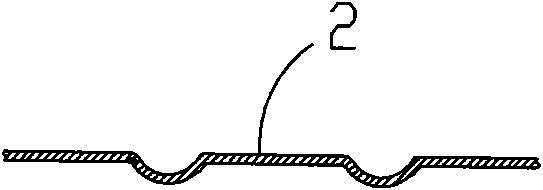

[0023] see figure 1 , Figure 2, in this embodiment, the flue gas discharged from the tail of the micro positive pressure fuel gas boiler is connected to the inlet smoke box 1 through a straight flue, and is located in the heat exchanger 4 between the inlet smoke box 1 and the outlet smoke box 3 The heat exchange element is set as a threaded pipe 2, and the top of the heat exchanger 4 is provided with a deaeration tower 5, and a water inlet spray pipe 7a is connected to the deaeration tower 5, and a water distribution plate 6 is arranged below the water inlet spray pipe 7a , the top of the deaerator tower 5 is provided with a steam escape outlet 5a;

[0024] The water inlet pipe of the automatic water inlet control system 7 is connected with the water inlet spray pipe 7a arranged in the deaeration tower 5, and the water level detection of the automatic water inlet control system 7 is arranged in the heat exchanger 4;

[0025] The heat exchanger 4 is provided with a condensed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com