Electronic temperature controller of transformer

A temperature controller and transformer technology, applied in the direction of temperature control using electric methods, can solve problems such as inconvenient use, complex structure, damage, etc., achieve the effects of easy installation and maintenance, compact system structure, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

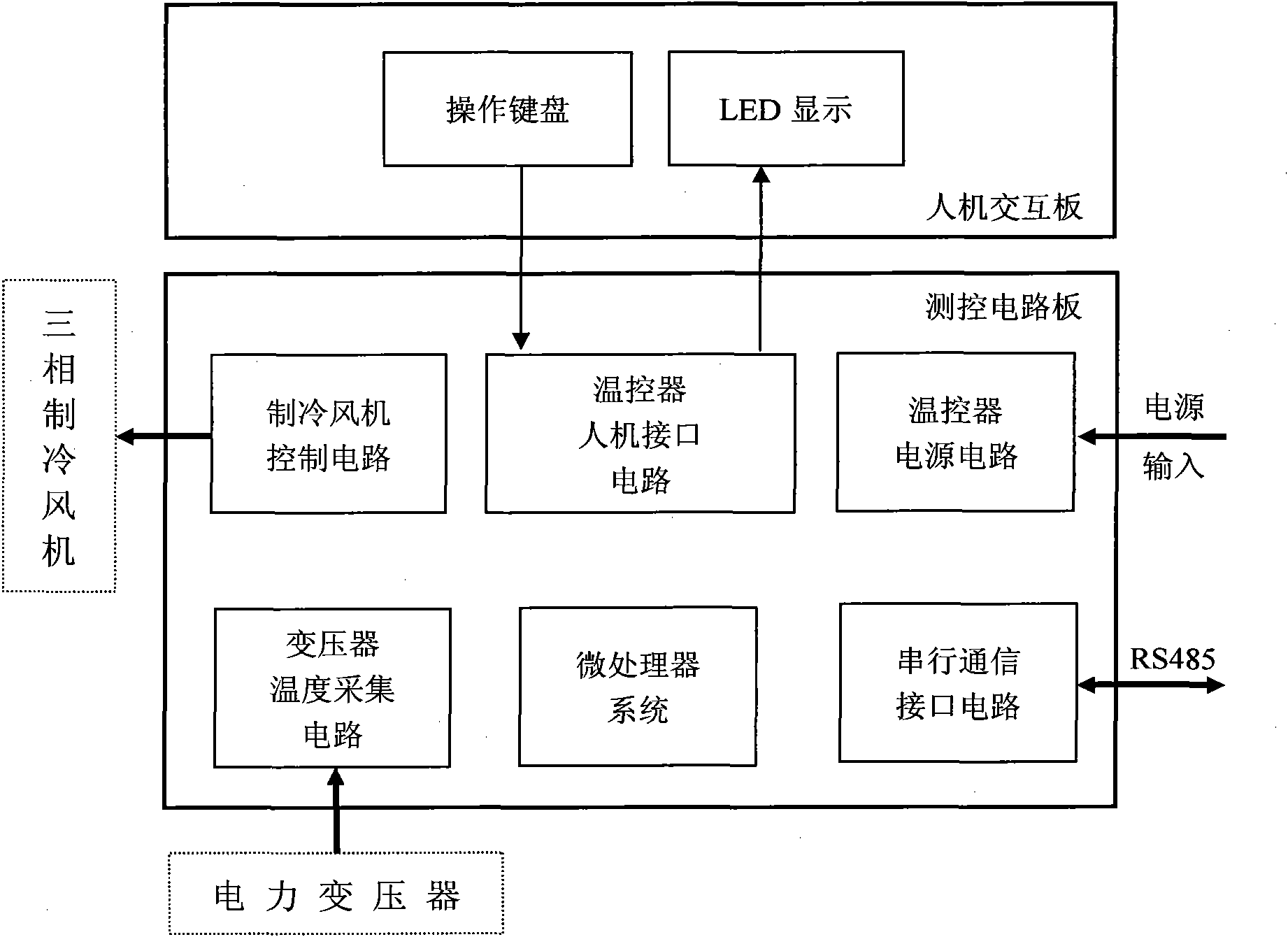

[0030] Accompanying drawing is a kind of specific embodiment of the present invention.

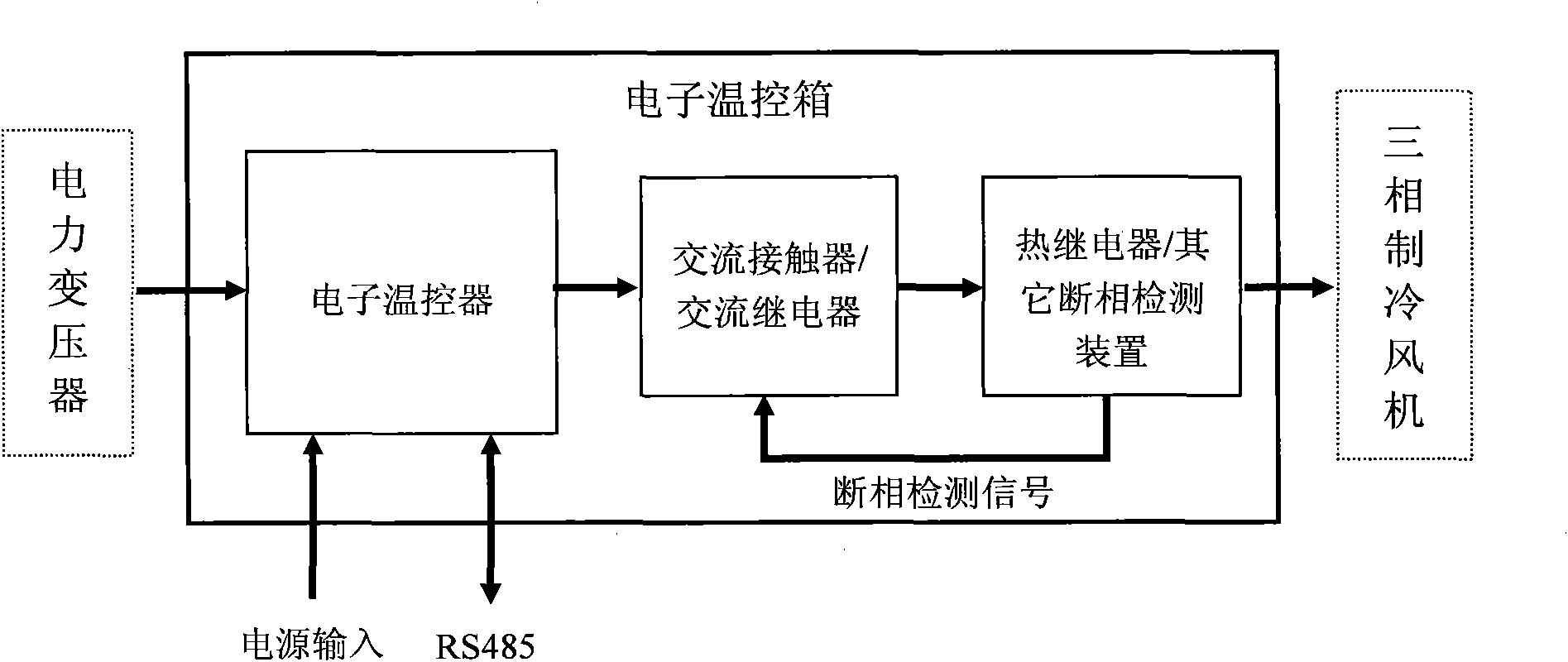

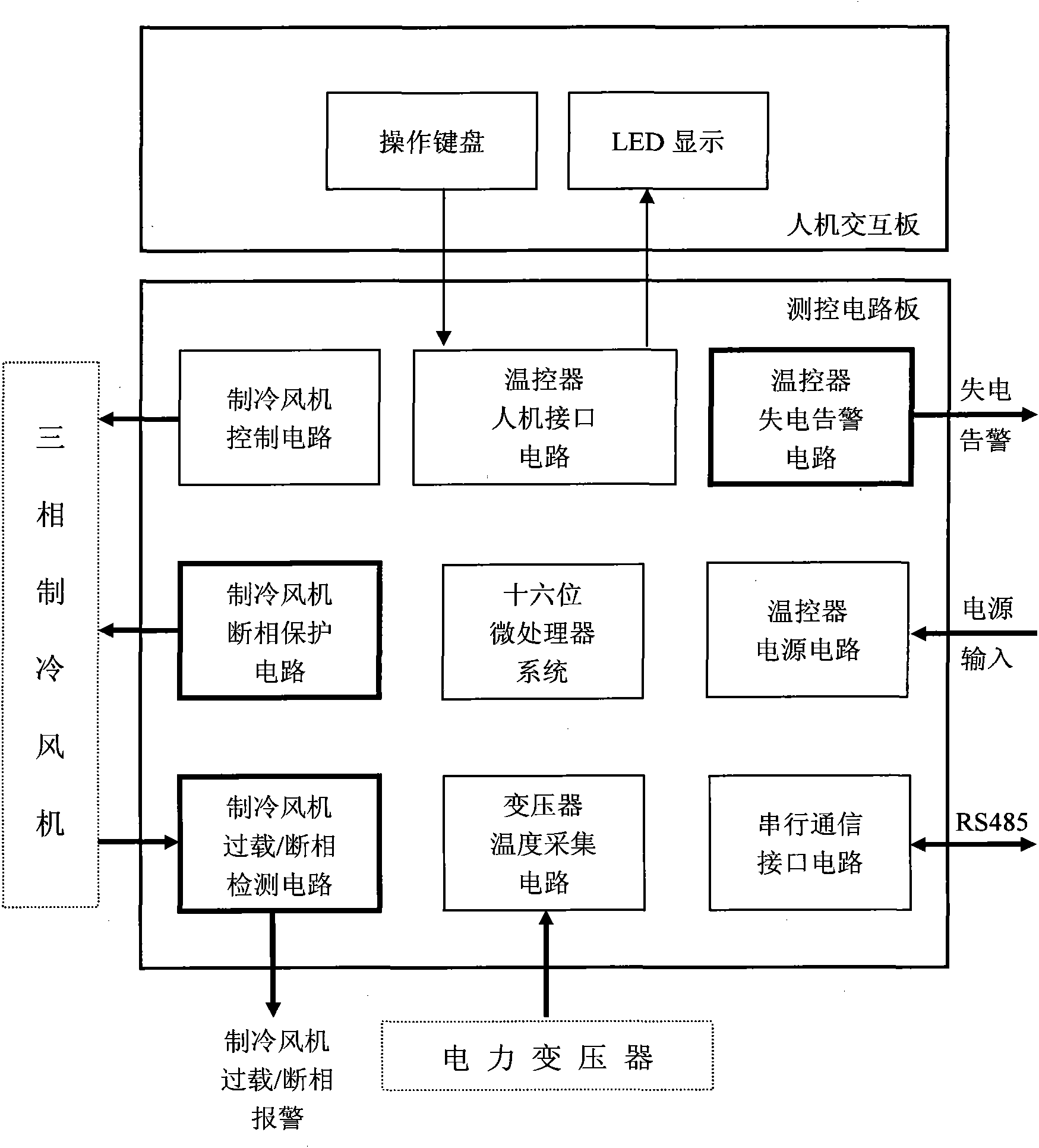

[0031] The transformer electronic temperature controller of the present invention includes a human-computer interaction board and a measurement and control circuit board. The human-computer interaction board is provided with an operation keyboard and a display. System, thermostat power supply circuit, transformer temperature acquisition circuit, serial communication interface circuit, air cooler control circuit connected to three-phase refrigeration fan, thermostat human-machine interface circuit connected to the operation keyboard and display of human-computer interaction board, thermostat The power supply circuit is connected to the power supply, the transformer temperature acquisition circuit is connected to the power transformer, and the serial communication interface circuit is connected to the external monitoring network through the RS485 line. Phase protection circuit; the input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com