Novel semi-feeding threshing concave plate screen

A semi-feeding, concave plate screen technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of separation of difficult-to-break grass and grains, large screening workload, low strength, etc. Long service life and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

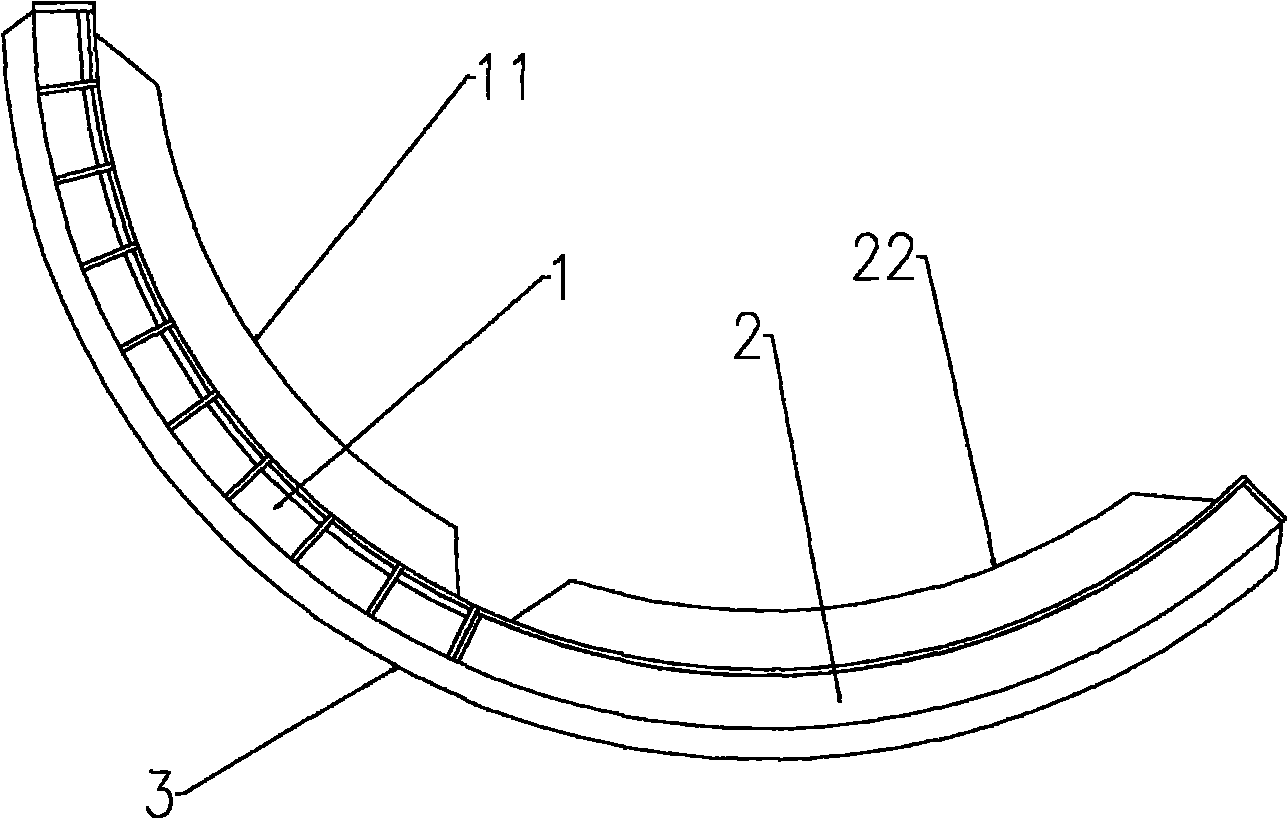

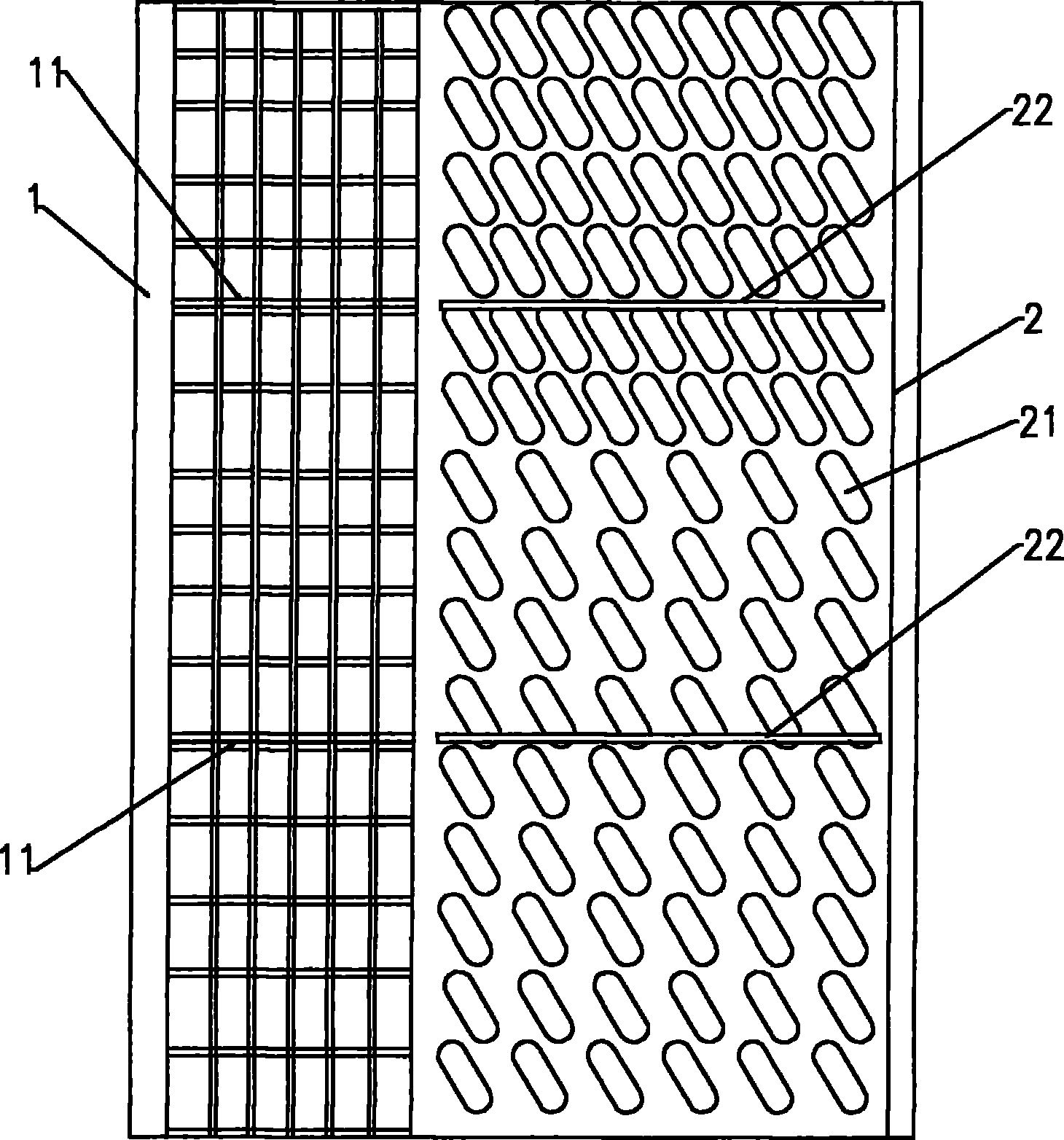

[0020] Such as figure 1 , figure 2 As shown, the present invention is a novel half-feed threshing concave plate screen, which is composed of a sieve plate and a partition for separating the sieve plates, and the sieve plate is formed by connecting a punching screen 2 and a grid screen 1, The highest point of the sieve plate is set at 1 / 2 height of the corresponding threshing drum. The lower side of the sieve plate is provided with several reinforcing ribs 3, which are respectively arranged on the lower side of the partition plate and the front and rear sides of the sieve plate, and coincide with the sieve plate. The partitions are divided into punching screen partitions 22 and grid screen partitions 11, which are respectively arranged on the upper side of the punching screen 2 and the grid screen 1, and the punching screen and the grid screen are correspondingly divided into 3 There are three threshing areas, and the punching screen is composed of three sieves, each threshi...

Embodiment 2

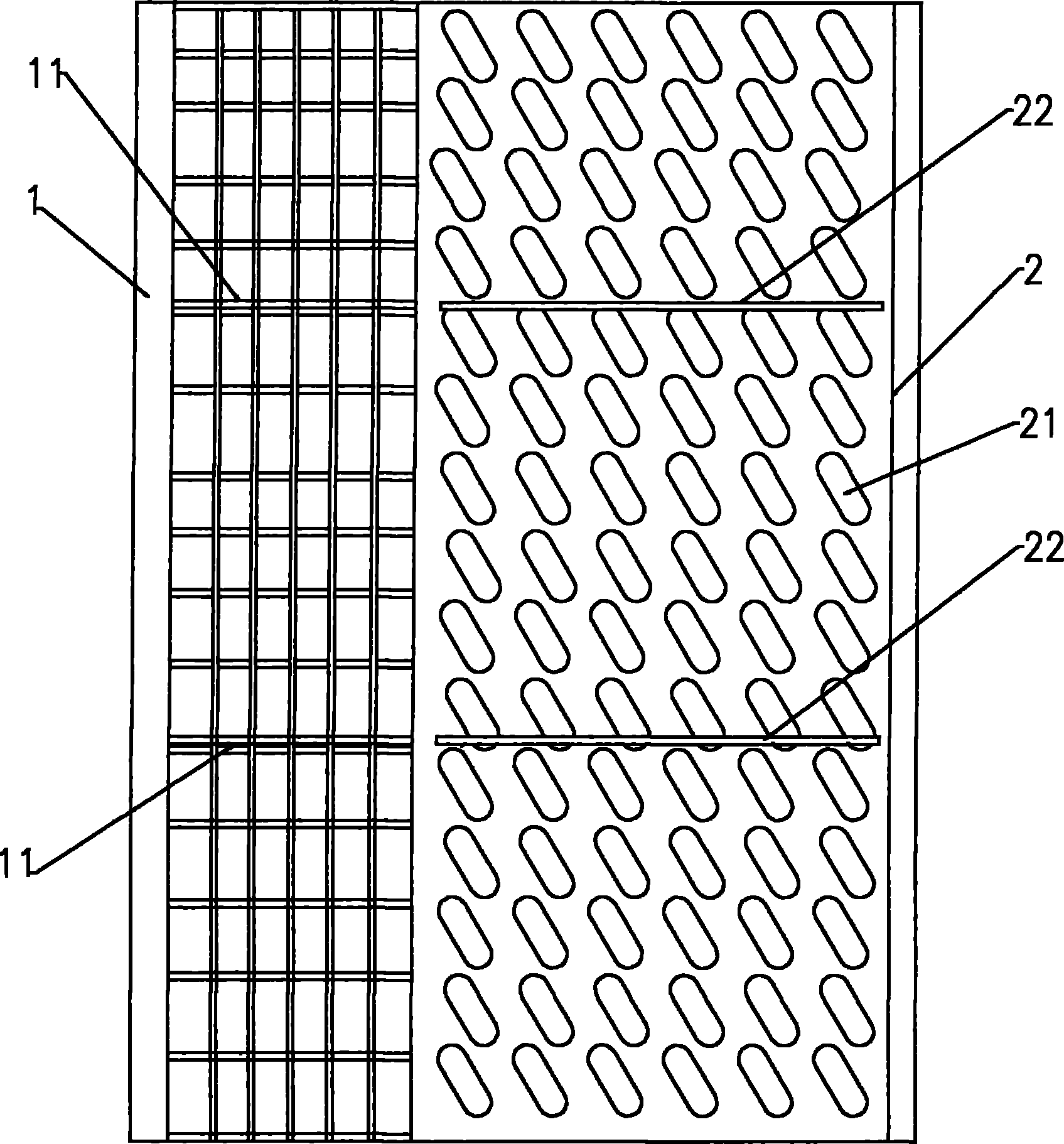

[0022] Such as image 3 As shown, the present invention is a novel half-feed threshing concave plate screen, which is composed of a sieve plate and a partition for separating the sieve plates, and the sieve plate is formed by connecting a punching screen 2 and a grid screen 1, The highest point of the sieve plate is set at 1 / 2 height of the corresponding threshing drum. The lower side of the sieve plate is provided with several reinforcing ribs 3, which are respectively arranged on the lower side of the partition plate and the front and rear sides of the sieve plate, and coincide with the sieve plate. The partitions are divided into punching screen partitions 22 and grid screen partitions 11, which are respectively arranged on the upper side of the punching screen and the grid screen, and the punching screen and the grid screen are correspondingly divided into three threshing The punching screen consists of three sieves, each threshing area corresponds to a sieve, and the pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com