Method for sealing plain filter membrane component

A filter membrane and flat sheet technology, which is applied in the sealing field of flat sheet filter membrane elements, can solve the problems of high material selection and complicated binder process, and achieve the effect of simple sealing and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

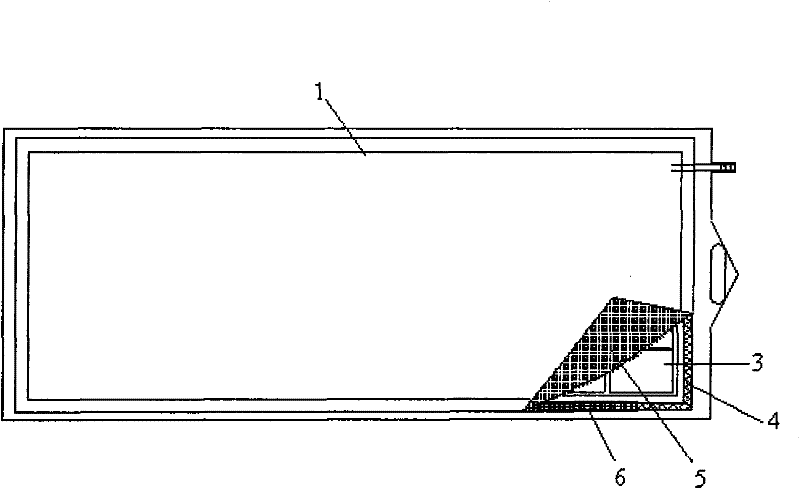

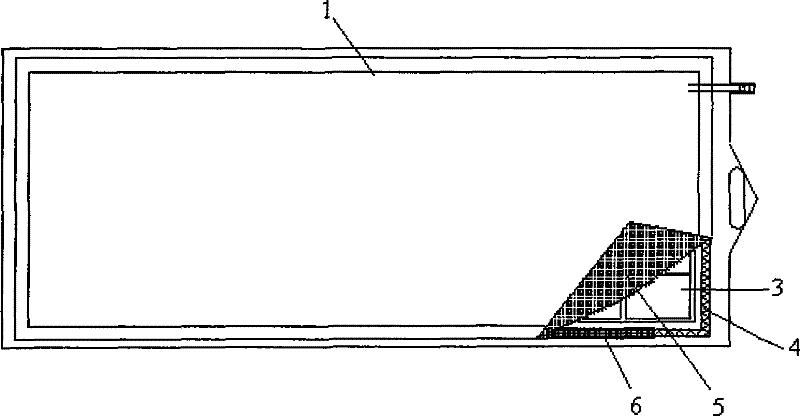

[0023] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0024] Such as figure 1 As shown, the flat-sheet filter membrane element includes a flow deflector 3 in the middle, and two flat-sheet filter membranes 1 covering both sides of the flow guide plate 3 . The material of the deflector 3 is generally ABS plastic, or other engineering plastics that are easy to be processed by injection molding. The substrate material of the filter membrane 1 is generally non-woven fabric, and most of them are polyester non-woven fabric or non-woven fabric of other polymer materials, such as polyethylene non-woven fabric. Because the sealing method of the present invention has wide applicability to materials, the deflector material and non-woven fabric substrate material commonly used in the MBR flat-sheet filter membrane element can be realized easily and wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com