Miniature electromagnetic broadband vibration energy harvester based on permanent magnet assay

A technology of vibration energy collection and permanent magnet array, which is applied in the field of micro-electromechanical and can solve the problems of numerous and complicated manufacturing process steps, difficult control of cantilever beam characteristics, and difficulty in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

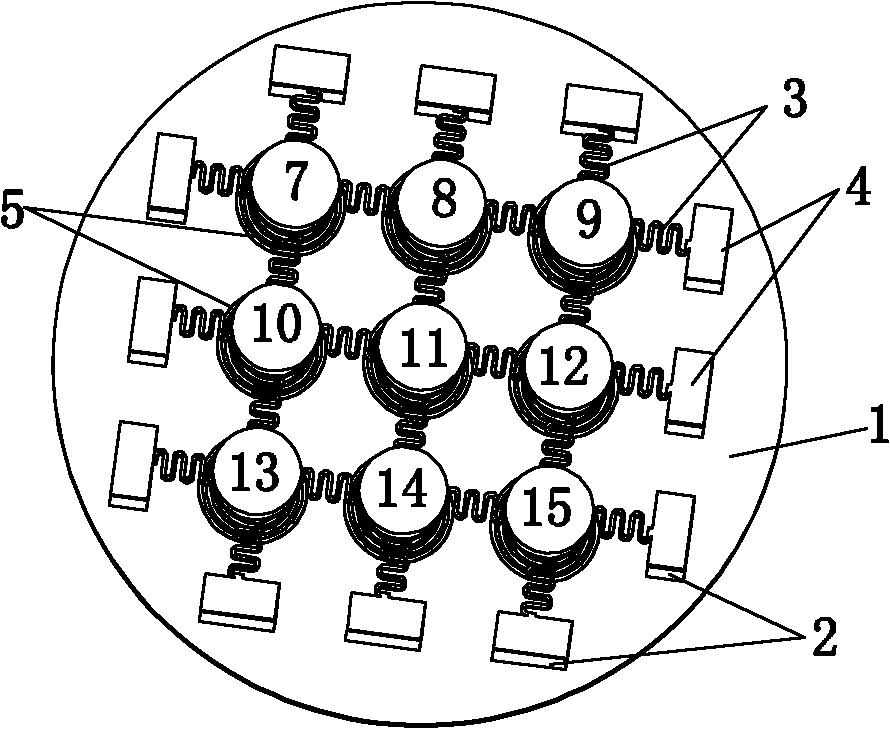

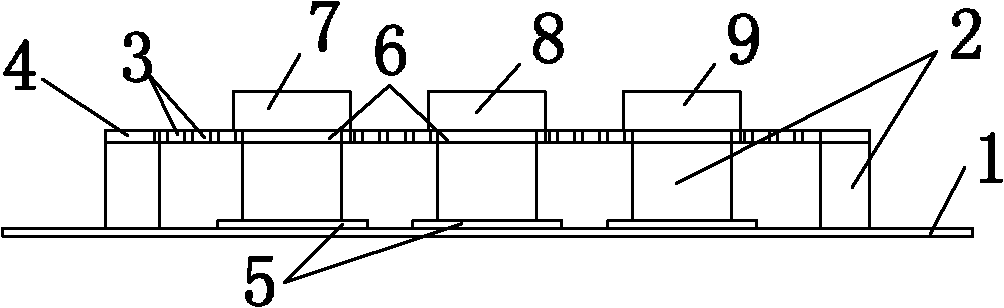

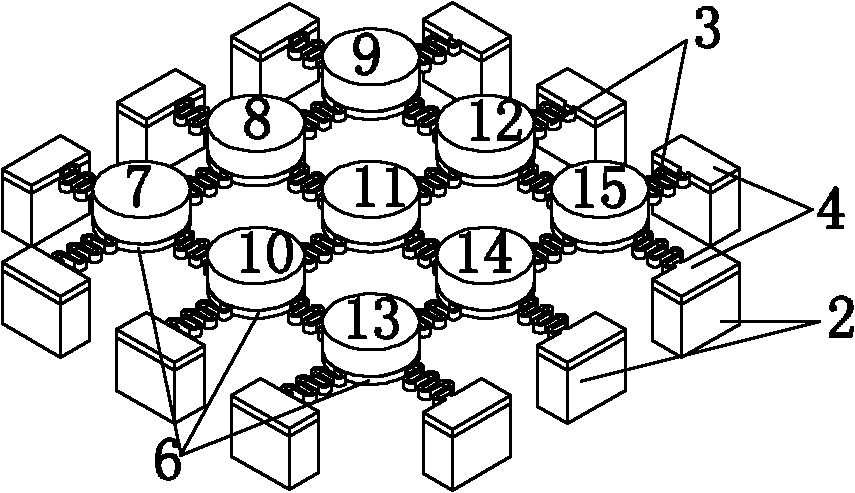

[0033] A miniature electromagnetic broadband vibration energy harvester based on a serpentine spring connected by a permanent magnet array composed of 9 circular permanent magnets

[0034] Such as figure 1 As shown, this embodiment includes: an insulating substrate 1, a planar spiral induction coil 5, twelve vibration pickup structures 3, 4, 6-15, and twelve corresponding support structures 2, of which: the insulating substrate 1, the planar The spiral induction coil 5 and the twelve vibration pick-up structures 3, 4, 6-15 are fixedly arranged from bottom to top, and the twelve support structures 2 are respectively located on the plane spiral induction coil 5 and the vibration pick-up structures 3, 4, 6-15 And fixedly connected with the insulating substrate 1.

[0035] The insulating substrate 1 is made of quartz or glass.

[0036] The plane spiral induction coil 5 is an induction coil winding structure, specifically a square or circular multi-layer multi-turn spiral metal copper co...

Embodiment 2

[0044] A miniature electromagnetic broadband vibration energy harvester based on a permanent magnet array composed of 9 circular permanent magnets connected by a polymer film

[0045] Such as Figure 4 As shown, the basic structure of this embodiment is the same as that of embodiment 1. The serpentine spring, connecting piece and gasket electroplating layer in embodiment 1 are connected by polymer film to realize the permanent magnet array and the permanent magnet array and support Flexible connection between structures.

Embodiment 3

[0047] Miniature electromagnetic broadband vibration energy harvester based on permanent magnet array sandwich structure

[0048] Such as Figure 5-7 As shown, this embodiment includes: a first insulating substrate 1 and a first planar induction coil 5 thereon, a vibration pickup structure 3, 4, 6-15, a first support structure 16, a second support structure 19, an inverted The second insulating substrate 17 and its second planar induction coil 18, in which: the first insulating substrate 1 and the second insulating substrate 17 are respectively arranged opposite to each other, and the first supporting structure 16 and the second supporting structure 19 are respectively located in the first insulating substrate. The inner side of the substrate 1 and the second insulating substrate 17 form a sandwich structure. The vibration pickup structures 3, 4, 6-15 are respectively located in the middle of the sandwich structure and the first planar spiral induction coil 5 and the second plana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com