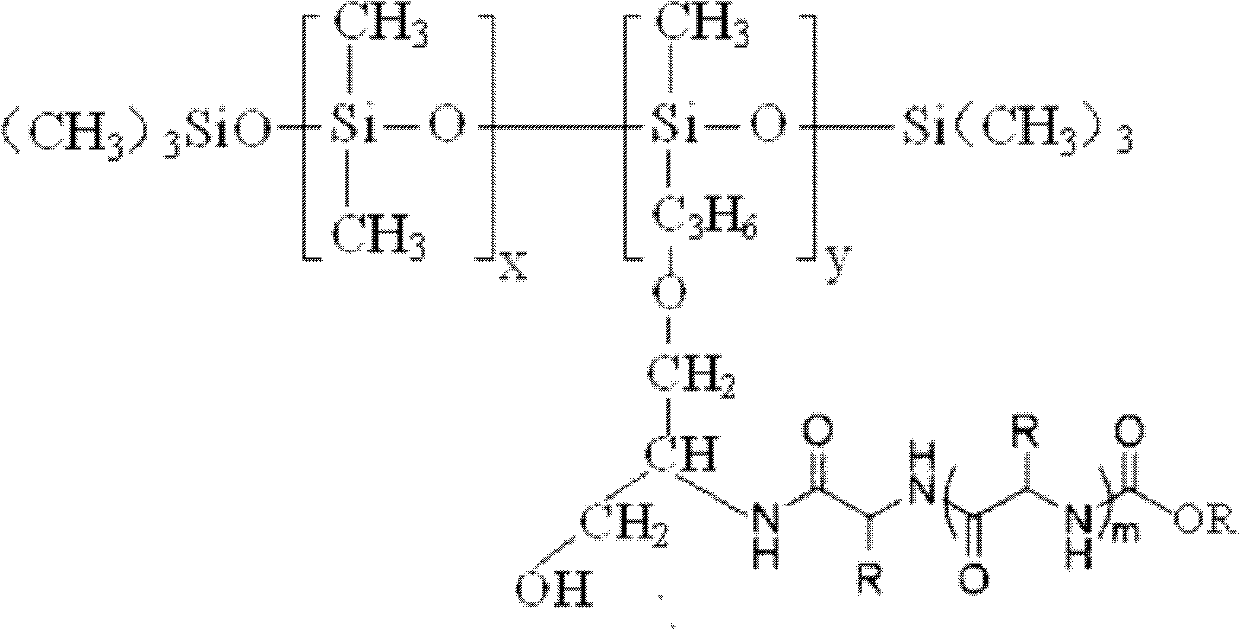

Polypeptide-siloxane copolymer and preparation method thereof

A technology of siloxane copolymer and polyorganosiloxane, which is applied in textiles, papermaking, fiber processing, etc., can solve the problems of insufficient, easy yellowing and hydrophilicity of amino silicone oil softener, and achieve the effect of good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

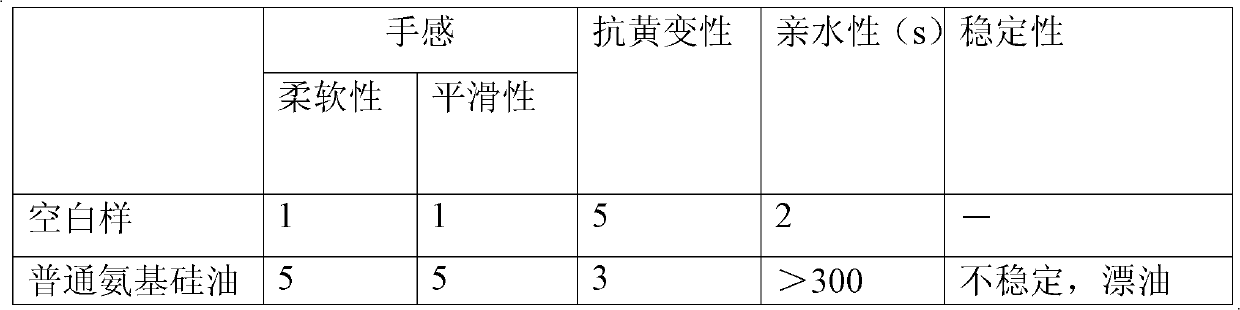

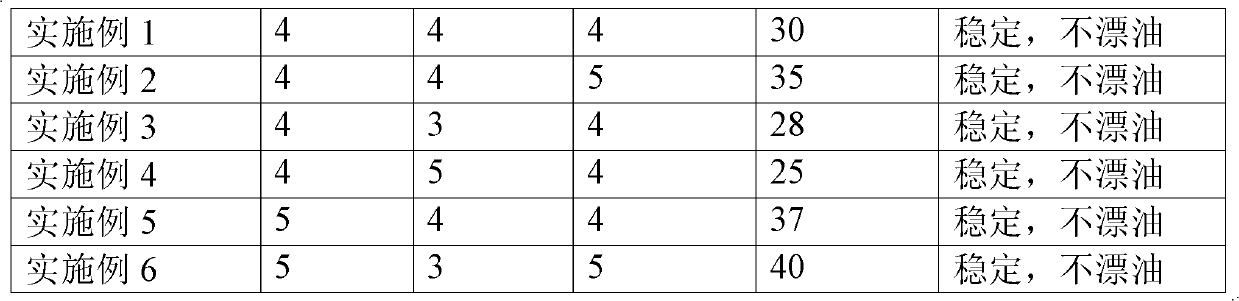

Examples

Embodiment 1

[0027] In a reaction vessel equipped with a stirrer, add 120 ml of toluene, 100 g of hydrogen-containing polyorganosiloxane (PDMHS) (H wt% = 0.05%, viscosity 210 mPa.s), 6.9 g of allyl glycidyl ether, 5g isopropanol, be warmed up to 70~80 ℃, add the chloroplatinic acid-isopropanol solution equivalent to 15ppm platinum, constant temperature reaction 6 hours, then decompressed and evaporated the solvent and excess allyl glycidyl ether to obtain ring Oxygen-polysiloxane intermediates.

[0028] 40 g of the polypeptide compound (soybean polypeptide) was dissolved in ethanol solution, the temperature was raised to 80° C., and the above intermediate was added. After 6 hours of reaction, the solvent was evaporated under reduced pressure to obtain a yellow cloudy liquid with a viscosity of 4650 mPa.s.

Embodiment 2

[0030] 6.9g of allyl glycidyl ether in Example 1 was changed to 7.5g of glycidyl acrylate. The remaining raw materials used are the same as those in Example 1, and the preparation steps are also the same as those in Example 1.

Embodiment 3

[0032] The soybean polypeptide in Example 1 was changed to sesame polypeptide. The remaining raw materials used are the same as those in Example 1, and the preparation steps are also the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com