Preparation method and application of zinc-aluminum-magnesium hydrotalcite-based PVC complex heat stabilizer

A composite thermal stabilizer, zinc magnesium aluminum water technology, applied in the direction of dyeing low-molecular-weight organic compounds, fibrous fillers, etc. Improve the effect of long-term thermal stability, prolonged thermal stability and easy process operation

Active Publication Date: 2011-01-12

湖南雄创新材料科技有限公司

View PDF0 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Lead and cadmium compounds are highly toxic to human health and pollute the environment. Organotin is expensive and has an odor

Now the non-toxic calcium and zinc composite stabilizer is a popular product, but the thermal stability of calcium and zinc soap-based stabilizers is not good, and people are looking for better new materials to cooperate with calcium and zinc soap. Heat stabilizers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

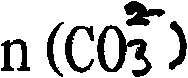

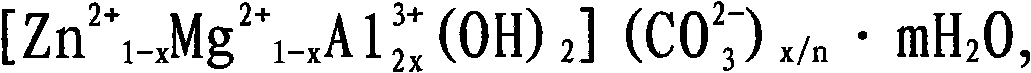

The invention relates to synthesis of novel zinc-aluminum-magnesium hydrotalcite and preparation of a PVC complex heat stabilizer from the hydrotalcite and calcium soap, zinc soap and the like according to a certain ratio. The complex heat stabilizer comprises the main components shown in the description, wherein X is more than or equal to 0.25 and less than or equal to 0.5, n is more than or equal to 0 and less than or equal to 0.1, and m is more than or equal to 0 and less than or equal to 4; while the popular hydrotalcite in market at present has the general molecular formula shown in the description. The complex heat stabilizer prepared from the hydrotalcite has the advantages of higher initial hue and long-lasting heat stability for PVC and other chlorine-containing high polymers, and has the characteristics of no toxin, no pollution, low cost, rich raw materials and the like.

Description

Technical field: The invention relates to synthesizing a novel zinc-magnesium-aluminum hydrotalcite for preparing a PVC composite heat stabilizer. Background technique: As we all know, PVC is easy to decompose under the condition of processing temperature, and a stabilizer must be added to make it process smoothly. A lot of research work has been done on the stabilization of PVC at home and abroad. So far, the widely used heat stabilizers are mainly basic lead salts, metal soaps (Ba, Cd, Ca, Zn), organotin compounds, etc. Lead and cadmium compounds are highly toxic to human health and pollute the environment. Organotin is expensive and has an odor. Now the non-toxic calcium and zinc composite stabilizer is a popular product, but the thermal stability of calcium and zinc soap-based stabilizers is not good, and people are looking for better new materials to cooperate with calcium and zinc soap. Heat stabilizers. Therefore, hydrotalcite, a new functional material, is applied...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08K13/06C08K9/04C08K5/098C08K5/07C09C1/40C09C3/08C08L27/06

Inventor 彭召林

Owner 湖南雄创新材料科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com