Integrated reverse engine

An engine, all-in-one technology, applied in the direction of machine/engine, mechanical equipment, control device, etc., can solve the problems of complicated process, high cost of reverse gear, installation interference, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

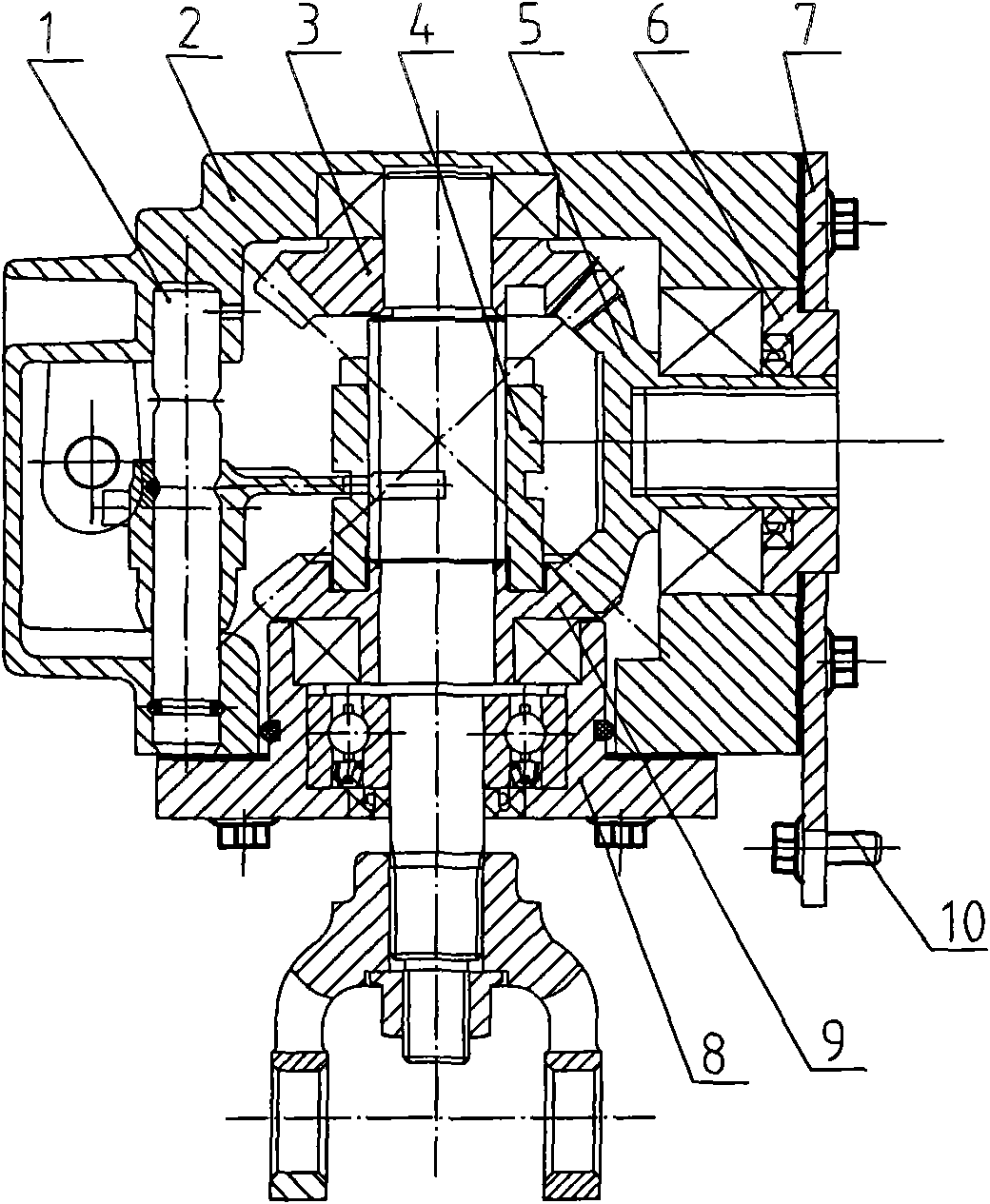

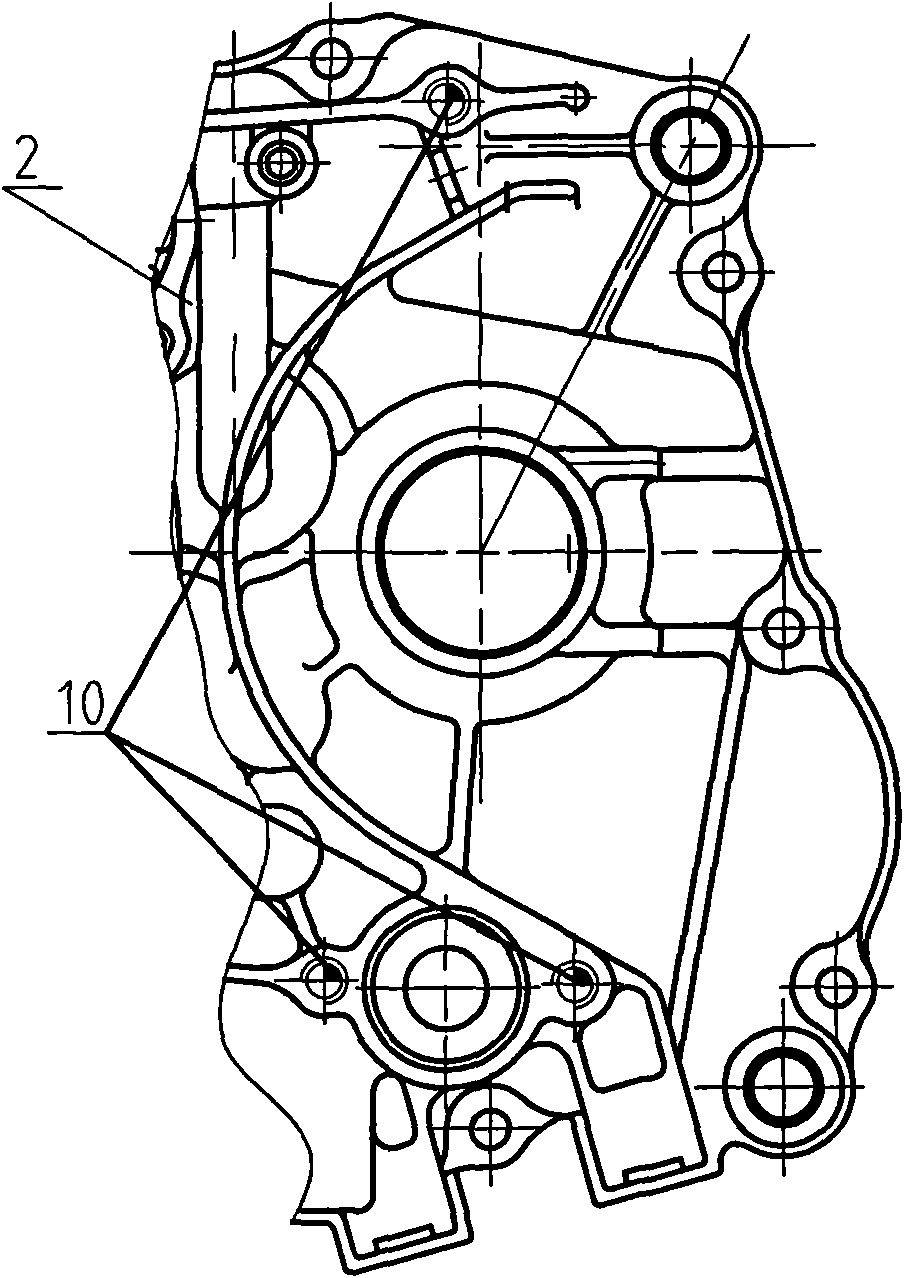

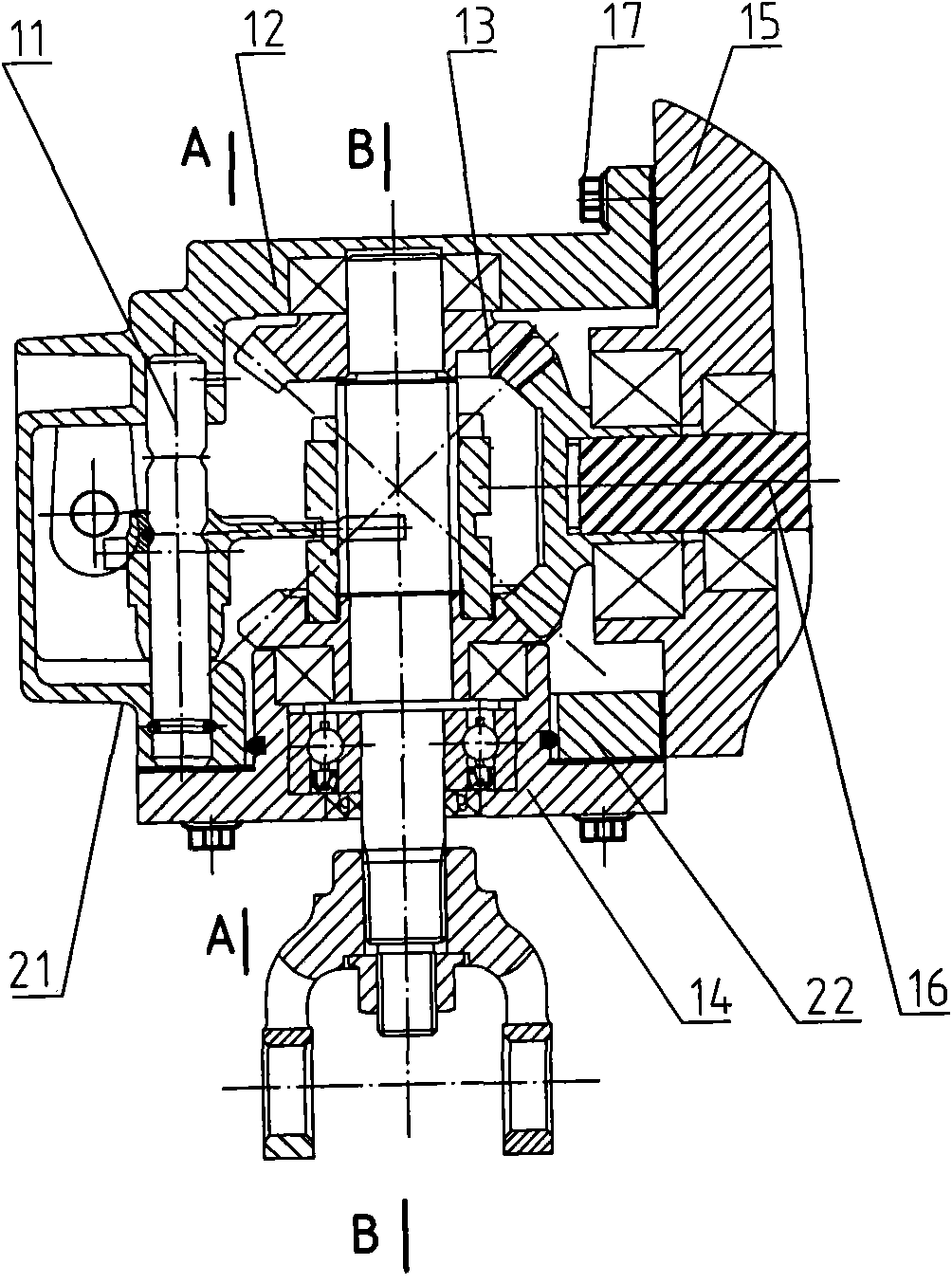

[0015] Such as figure 1 , 2 Middle, 1-reverse gear operating mechanism, 2-reverse gear housing, 3-reverse gear, 4-reverse clutch, 5-reverse gear drive gear, 6-transition body, 7-connecting plate, 8-tailstock , 9-forward gear, 10-connecting bolt;

[0016] figure 1 , 2 The structure of the external reverse gear device shown in the prior art usually uses connecting bolts 10 to connect the connecting plate 7 to the reverse gear housing 2 and the engine case, and uses the connecting plate 7 to connect the reverse gear housing 2 to the engine case. Connected and fixedly connected into one; the reverse gear operating mechanism 1, the reverse gear 3, the reverse clutch 4, the reverse gear drive gear 5, the tailstock 8, the forward gear 9, etc. are all set and installed in the reverse gear housing 2, When it is necessary to reverse the vehicle, the power output shaft is reversed (opposite to the rotation direction of the forward gear) to realize the reverse gear function. This kin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com