Integrated environmentally-friendly stove

A technology integrating environmental protection stoves and bodies, applied in the field of kitchen stoves, can solve the problems of difficulty in purifying oil fume, reducing the distance between the smoking port and the stovetop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

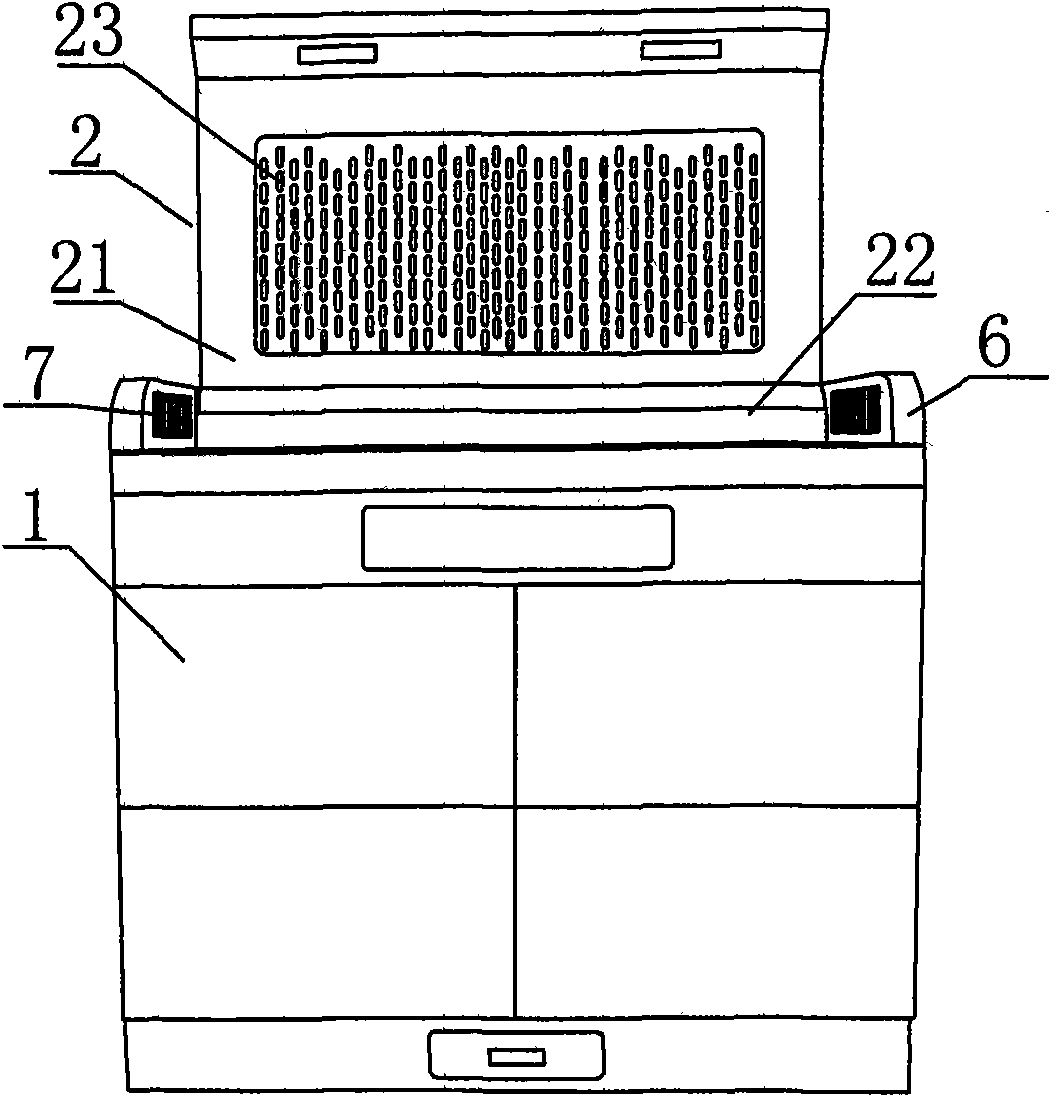

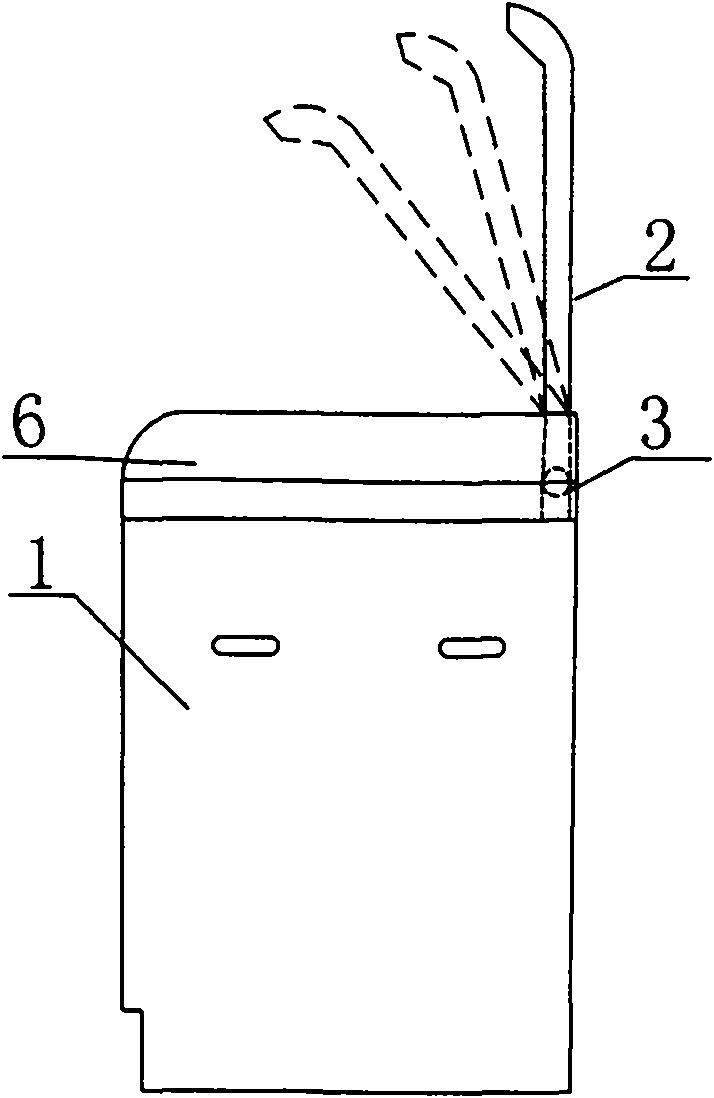

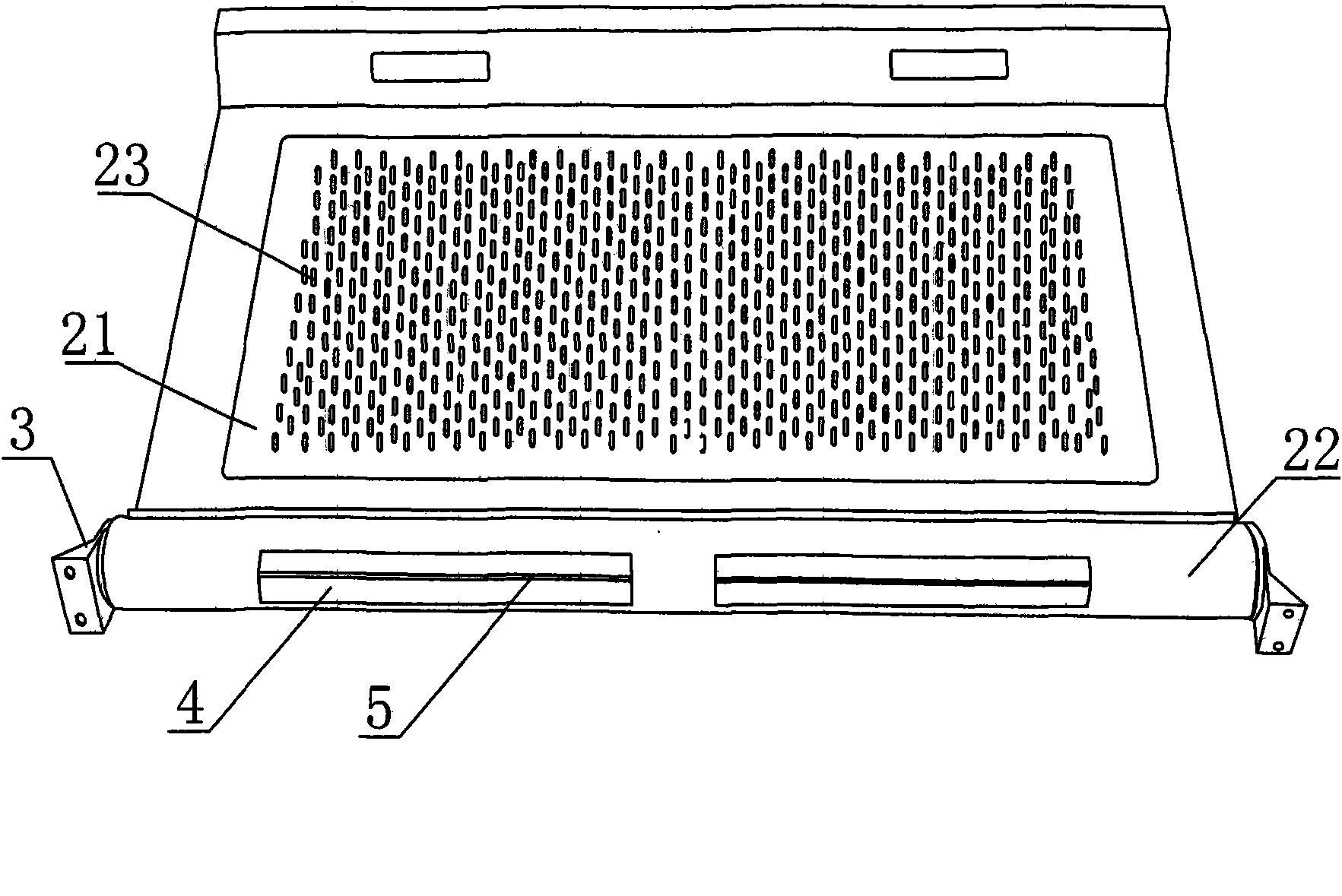

[0022] refer to figure 1 , figure 2 , image 3 , an integrated environment-friendly stove, including a body 1 and a flip cover 2 arranged on the top of the body 1, the flip cover 2 is composed of a panel 21 with a smoking hole 23 and a rotating bar 22 arranged at the bottom of the panel 21, the two sides of the rotating bar 22 Each end is provided with a rotating part 3, the rotating part 3 is fixed on the body 1, so that the flip cover 2 can stop at different positions at any time during the rotation process; the rotating bar 22 is hollow, and the side wall is provided with a through The hole 4 makes the inside of the panel 21 communicate with the inside of the body 1 through the rotating bar 22 .

[0023] Refer again Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , the rotating member 3 includes a support 31, on which a flip shaft 32 is provided, and on the support 31, a circle of circular grooves 33 is arranged around the flip s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com