Virtual construction system of full-face tunneling boring machine

A technology of full-section roadheader and roadheader, which is applied in the direction of educational appliances, instruments, teaching aids, etc., can solve the problems of high cost and long cycle, and achieve the effect of low cost and convenient training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

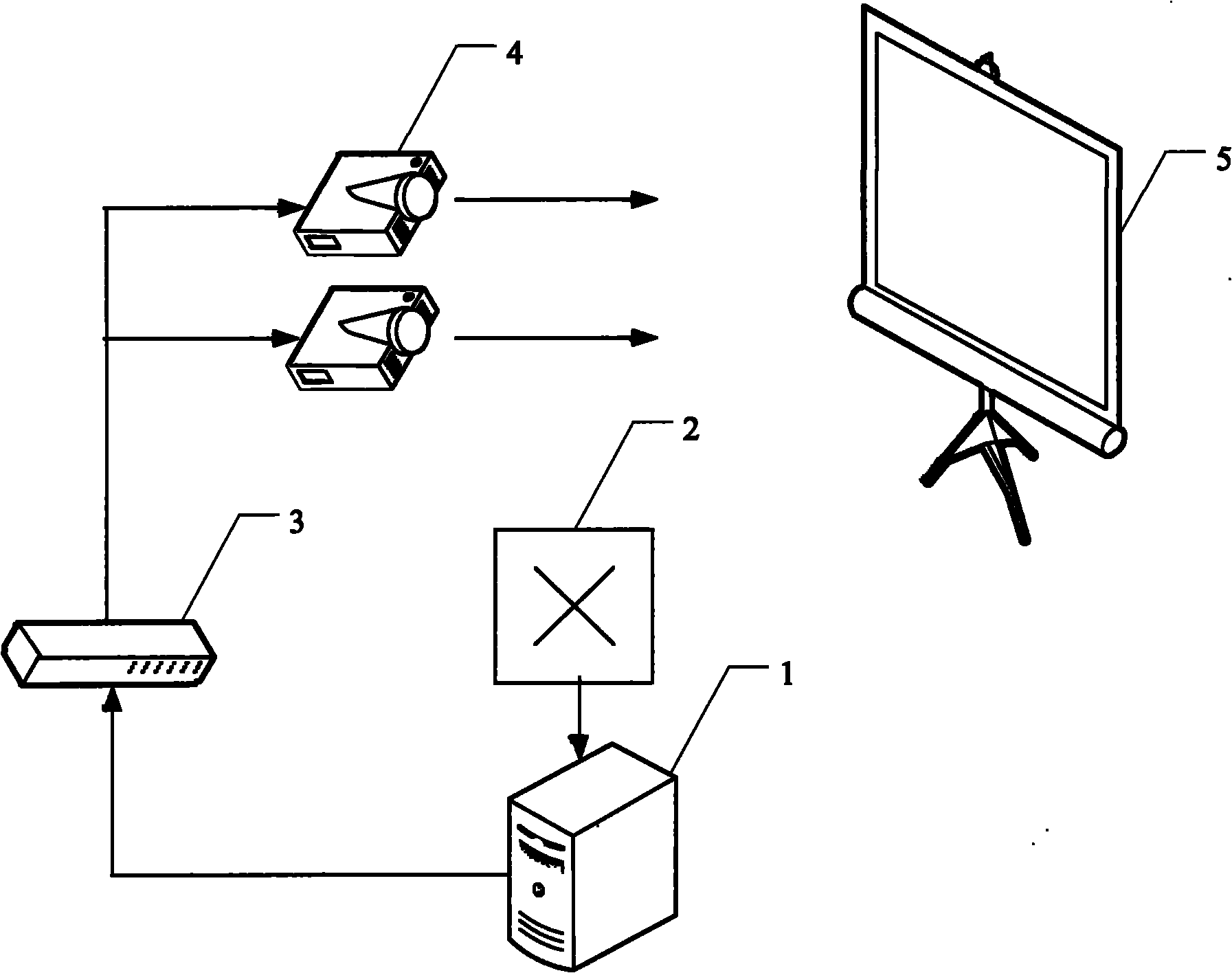

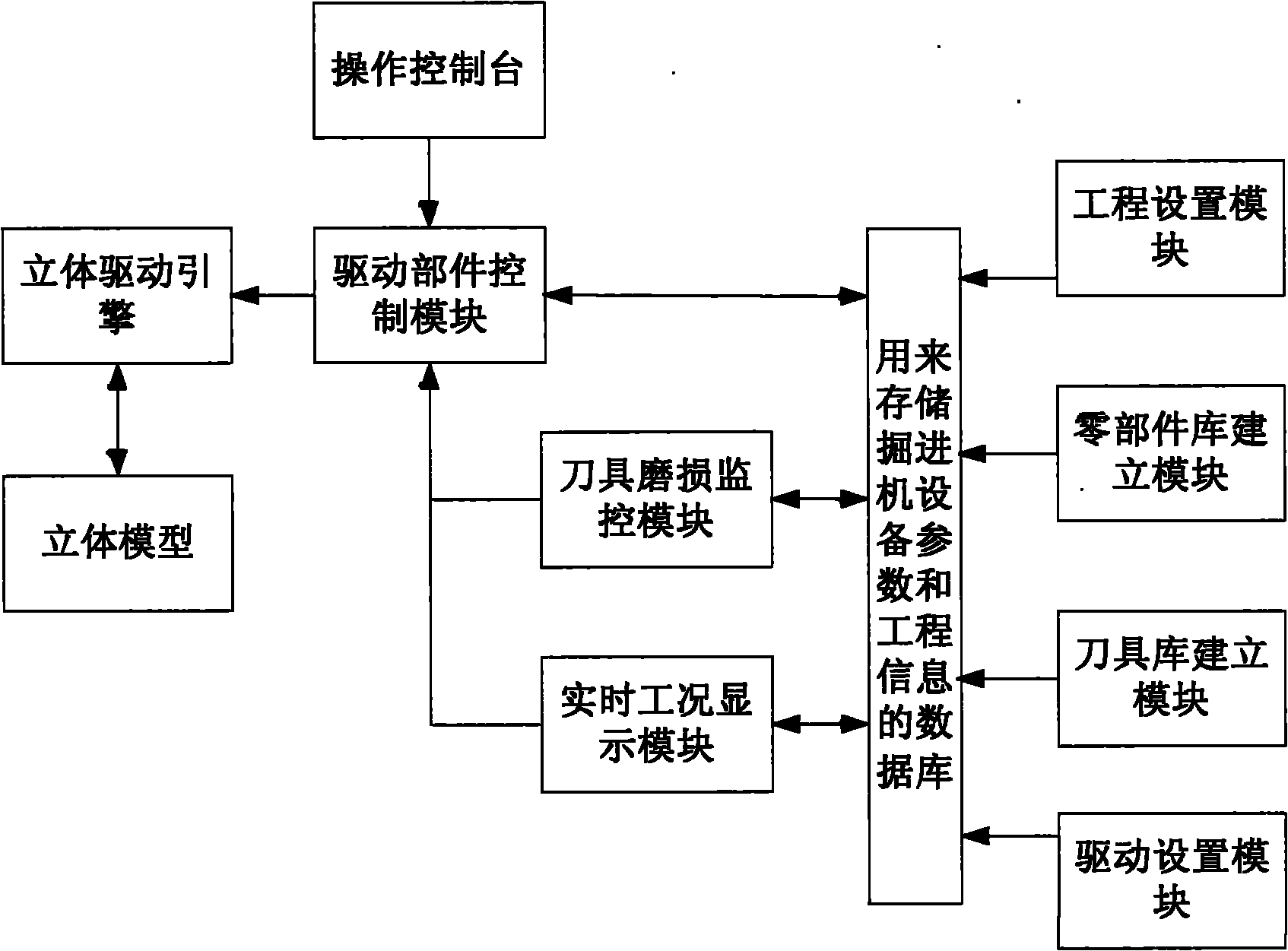

[0041] See attached figure 1 , the virtual construction system of the full-section roadheader of the present invention includes a graphics workstation 1, an operation console 2 and a stereo converter 3 are connected to the graphics workstation 1, and two stereoscopic projection lenses with polarized light are connected to the stereo converter 3 The projector 4 is provided with a metal stereoscopic projection screen 5 for receiving projection in front of the projector 4. Control buttons are provided on the operation console 2, including the opening and closing control buttons of the boring machine, the forward and reverse rotation control buttons of the cutter head, the forward and backward movement buttons, forward and reverse rotation buttons, and telescopic buttons of the segment installation machine. And the stop c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com