Heat dispersion control method for vehicle electronic control unit

A technology of electronic control unit and control method, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of chip burnout, thermal stability cannot be guaranteed, etc., and achieve the effect of ignoring switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is described in detail below in conjunction with accompanying drawing:

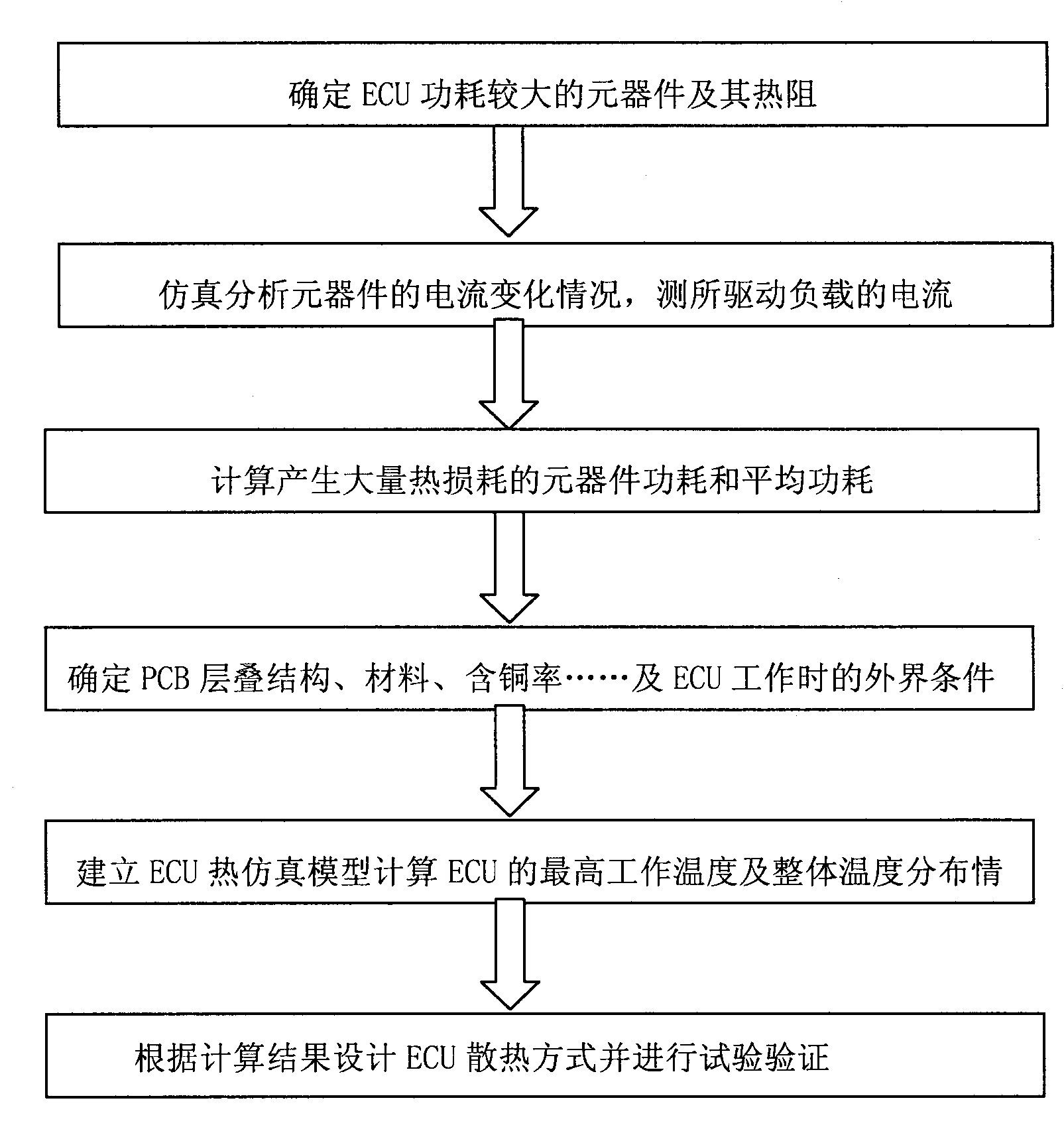

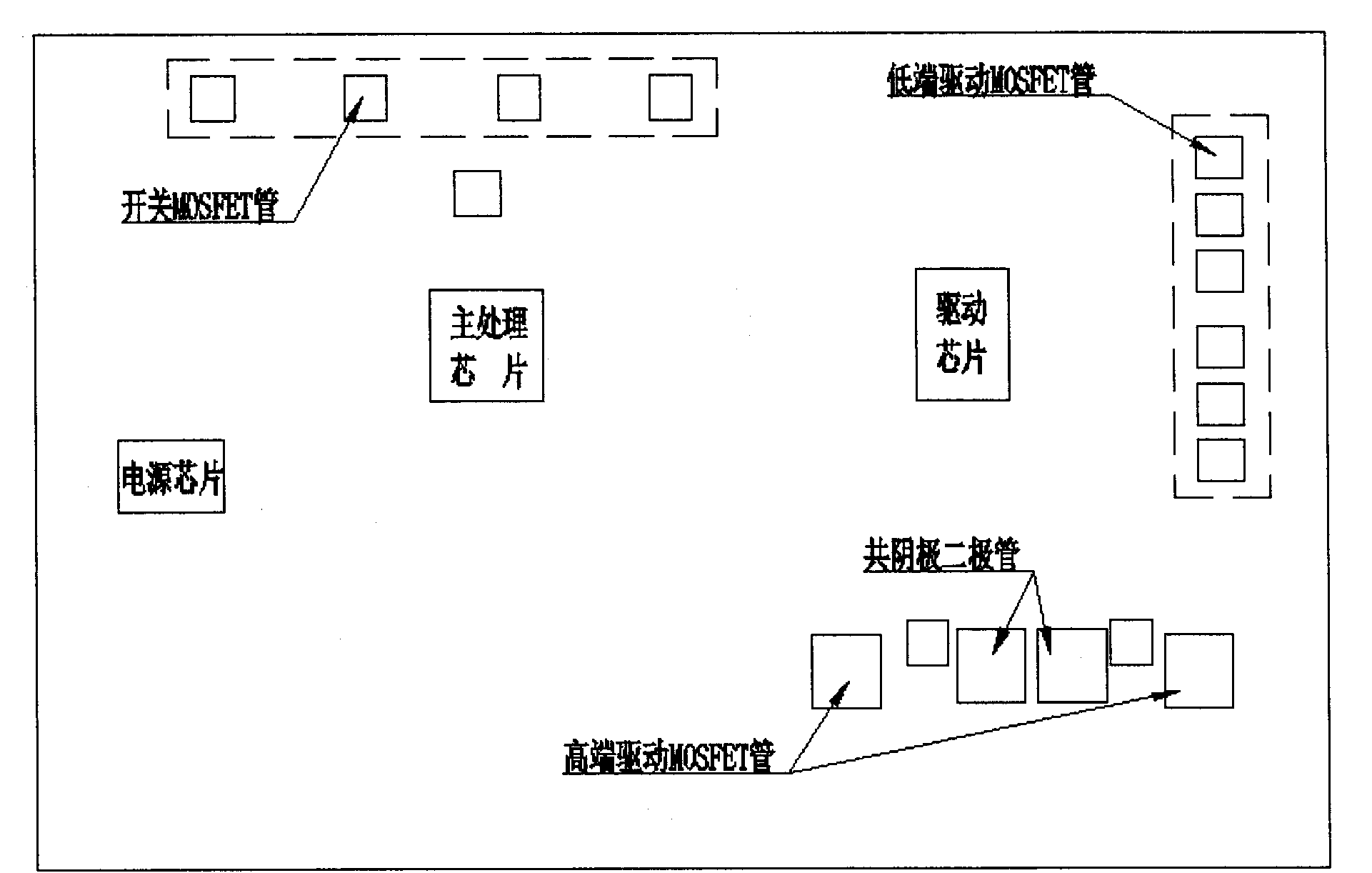

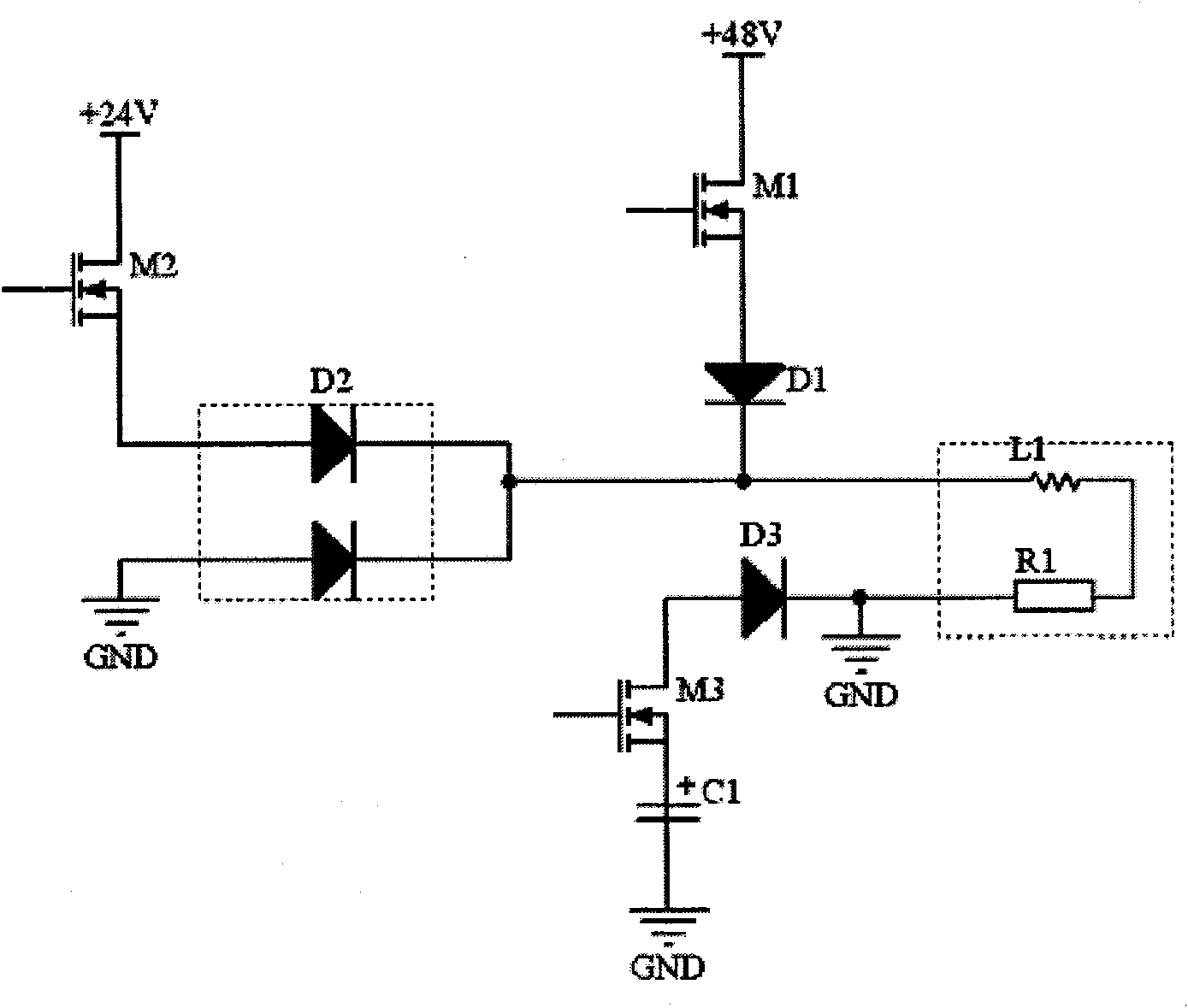

[0069] The heat dissipation control method of the electronic control unit for a vehicle according to the present invention does not depend on external conditions, by changing the shell structure of the electronic control unit for a vehicle and the PCB (printed circuit board) board in the electronic control unit for a vehicle The layout of high-power components with a rated power ≥ 50mw improves the heat dissipation of the electronic control unit for vehicles as much as possible. It can also be said that the heat dissipation control method of the electronic control unit for vehicles described in the present invention is a design control method combining software simulation test and sample test. First, analyze and calculate the power consumption of high-power components with rated power ≥ 50mw when the electronic control unit for vehicles is working, and simulate high-power comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com