Device for the automatic suction power regulation of a vacuum cleaner

An automatic adjustment and vacuum cleaner technology, which is applied in the installation of vacuum cleaners, vacuum cleaner equipment, and electrical equipment, and can solve problems such as increased sliding resistance of suction nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following description of the preferred embodiments of the present invention, the same reference numerals denote the same or similar components.

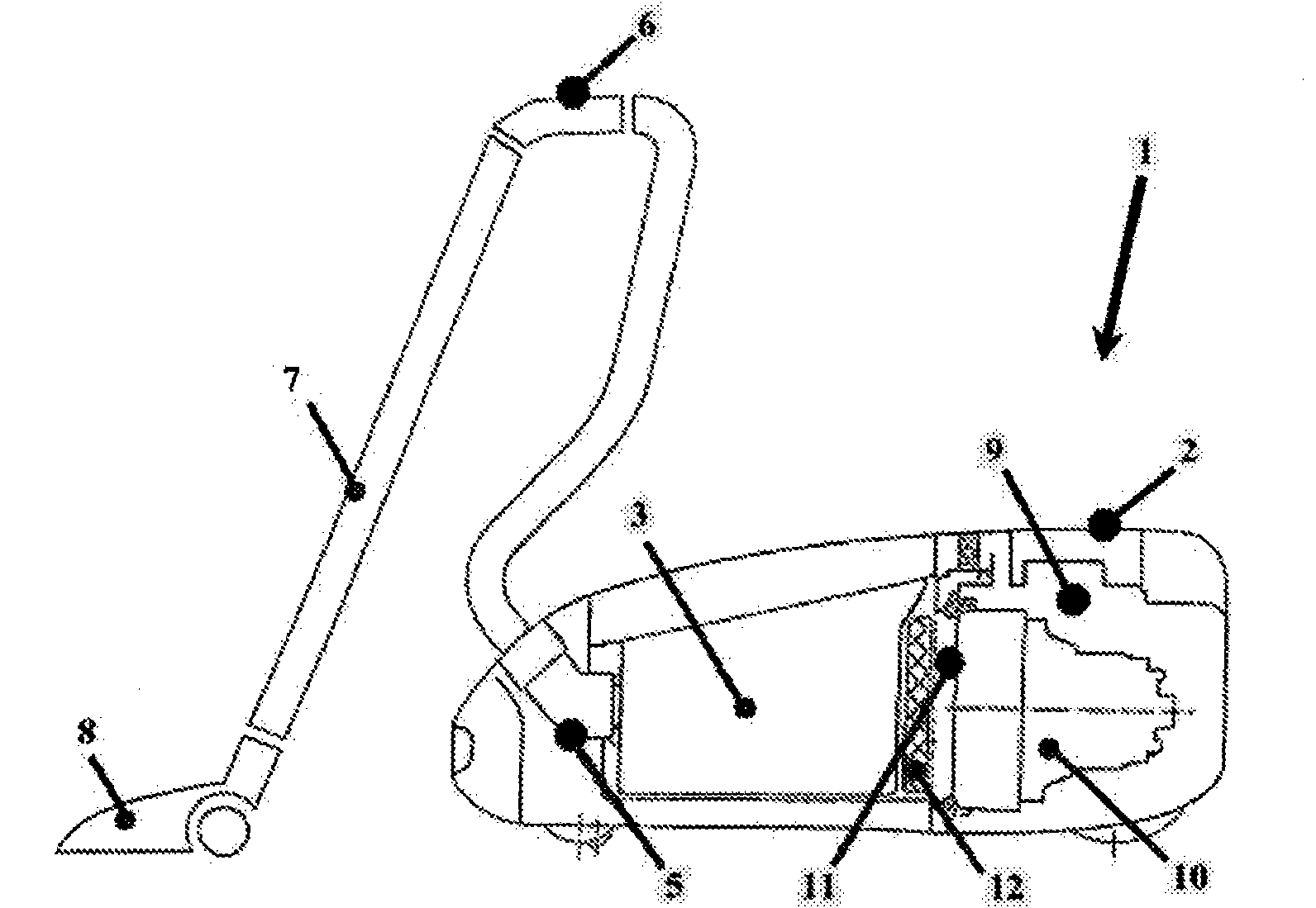

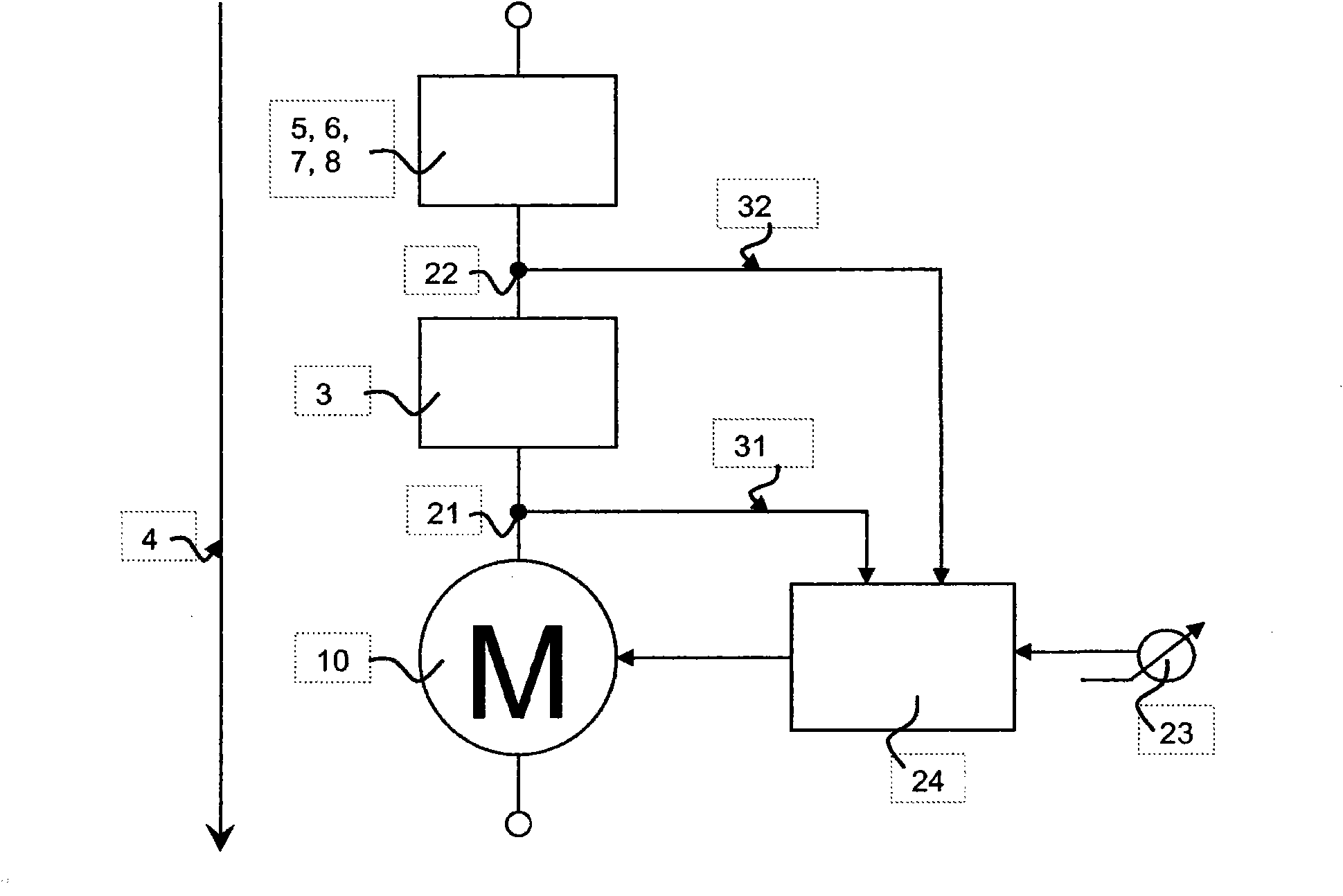

[0028] figure 1 A vacuum cleaner 1, in this case a floor vacuum cleaner, is schematically shown, comprising a vacuum cleaner housing 2 and a dust separation unit 3 housed in the vacuum cleaner housing, which is located in the suction air flow 4 and is connected via a pipe connection 5 and a suction hose with a handle 6. The pipe is connected to the suction nozzle 8 through a connecting pipe 7 with variable length. A motor / fan unit 10 is provided in the motor / fan compartment 9 , and a motor protection filter 12 is usually provided before the motor / fan unit 10 in the motor / fan compartment.

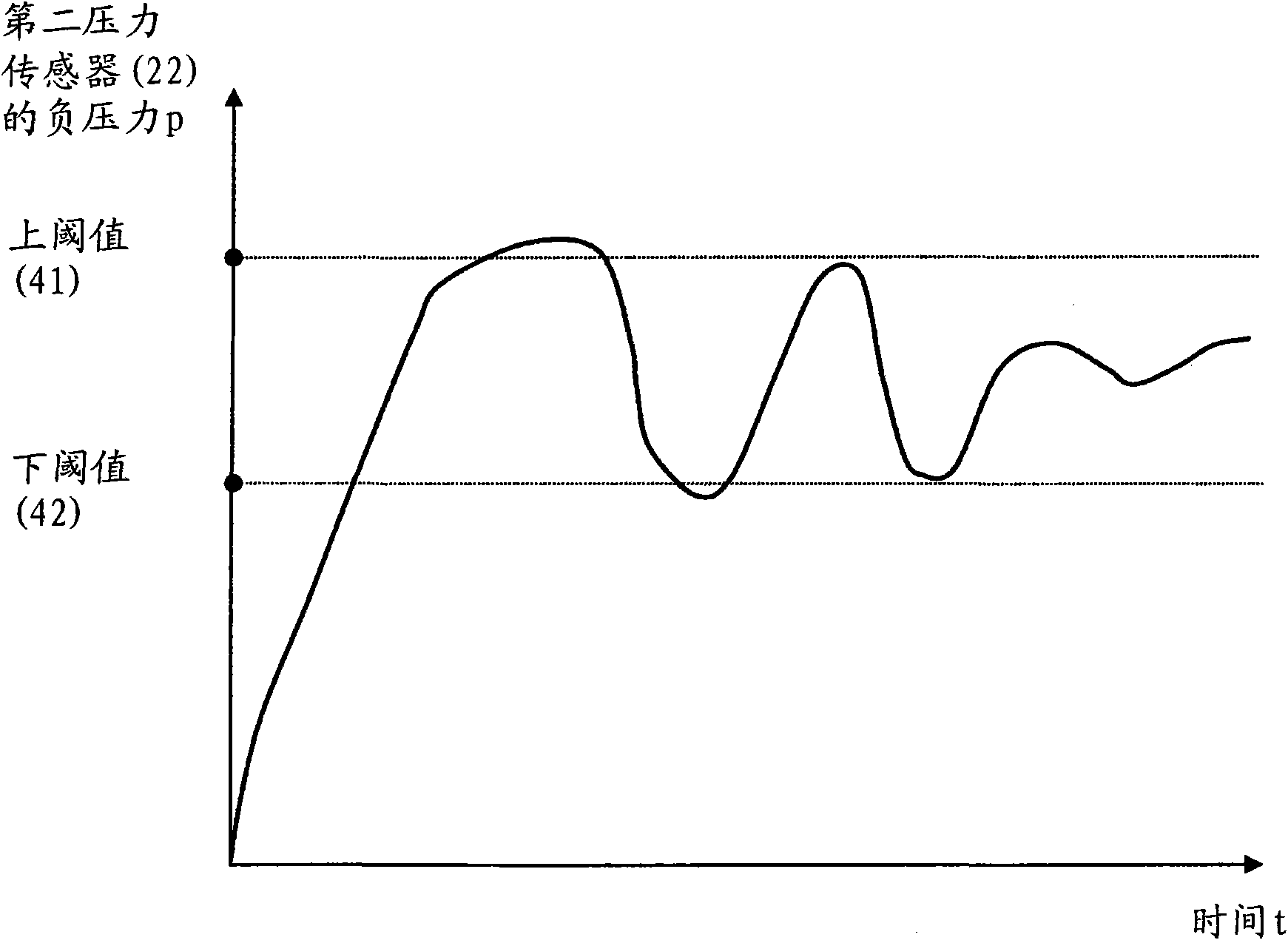

[0029] The dust separation unit 3 is represented in this description not only as a known dust filter bag, but also as a so-called bagless unit. The fine dust contained in the suction action gradually blocks or closes the pores of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com