Spindle having individual drive

A driving device and spindle technology, which is applied in the continuous winding spinning machine, textile and paper making, spinning machine, etc., can solve the problem of high maintenance cost, and achieve the effects of easy maintenance, good sealing and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

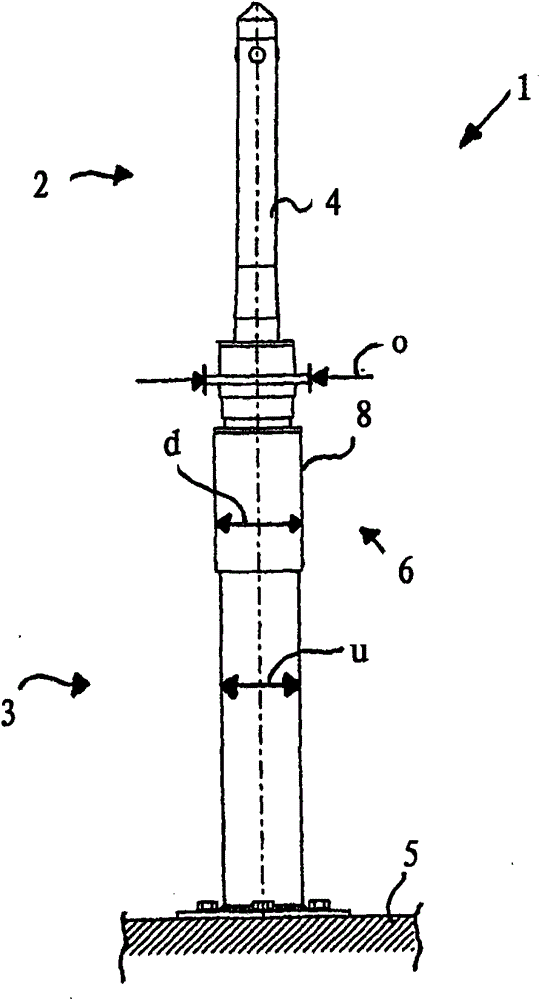

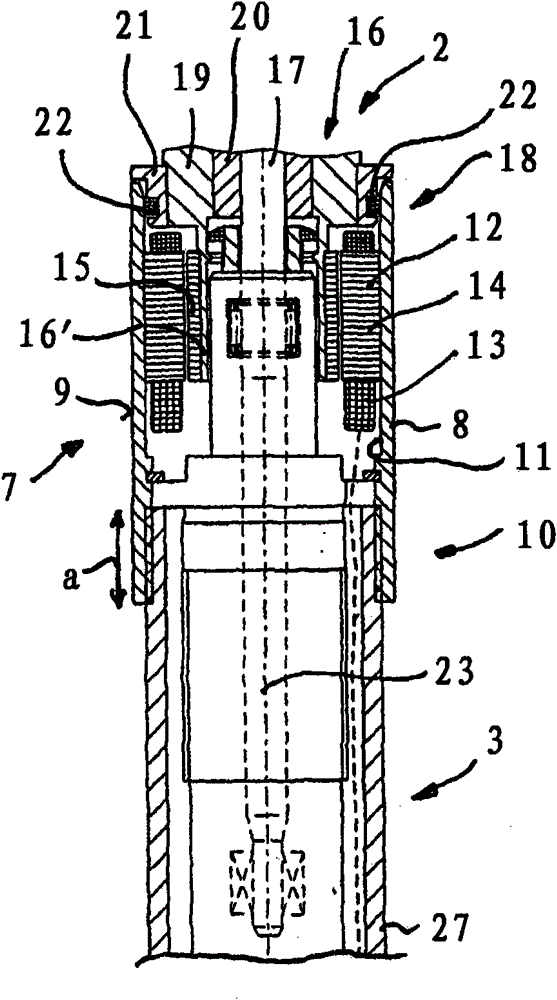

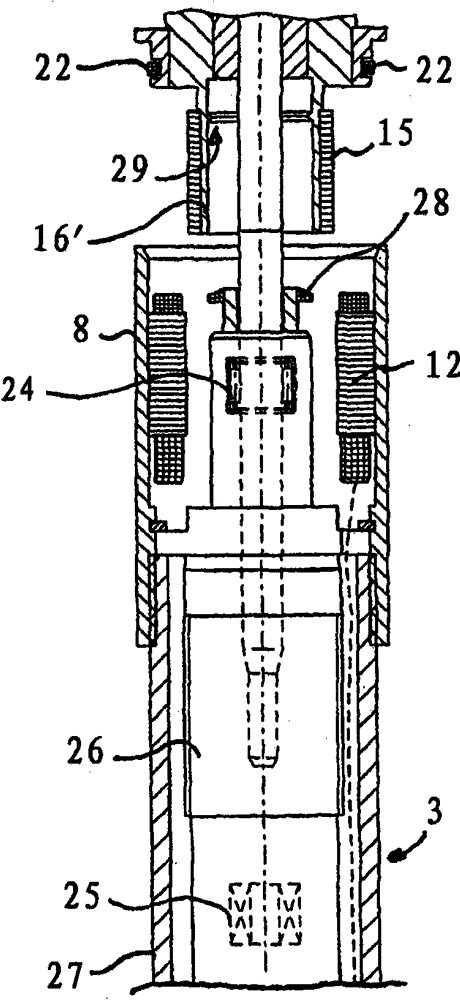

[0017] The spinning machine comprises a plurality of spindles 1 which can be arranged at a predetermined clearance distance from one another, for example 70 mm. The spindle 1 mainly consists of a spindle upper half 2 and a spindle lower half 3 . The upper spindle half 2 has a bobbin holder 4 on which the yarn or fiber is applied. The lower spindle half 3 is fixed on a preferably movable platform 5 by fastening screws.

[0018] In the central region 6 of the spindle 1 is arranged an electromechanical drive 7 for driving the upper spindle half 2 . The electromechanical drive 7 is covered in the peripheral direction by a stator housing part 8 , wherein the stator housing part 8 has an outer wall 9 with a constant outer diameter d. The outer diameter d may be, for example, 40 mm. The outer diameter d of the stator housing part 8 is slightly larger than the outer diameter u of the lower spindle half 3 . The outer diameter d of the stator housing part 8 is preferably at most gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com