Device for removing a liquid or solid particles from a flat surface of a metal product

A metal product, flat surface technology, used in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problem of emulsion dripping not fully functioning, and achieve the effect of anti-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

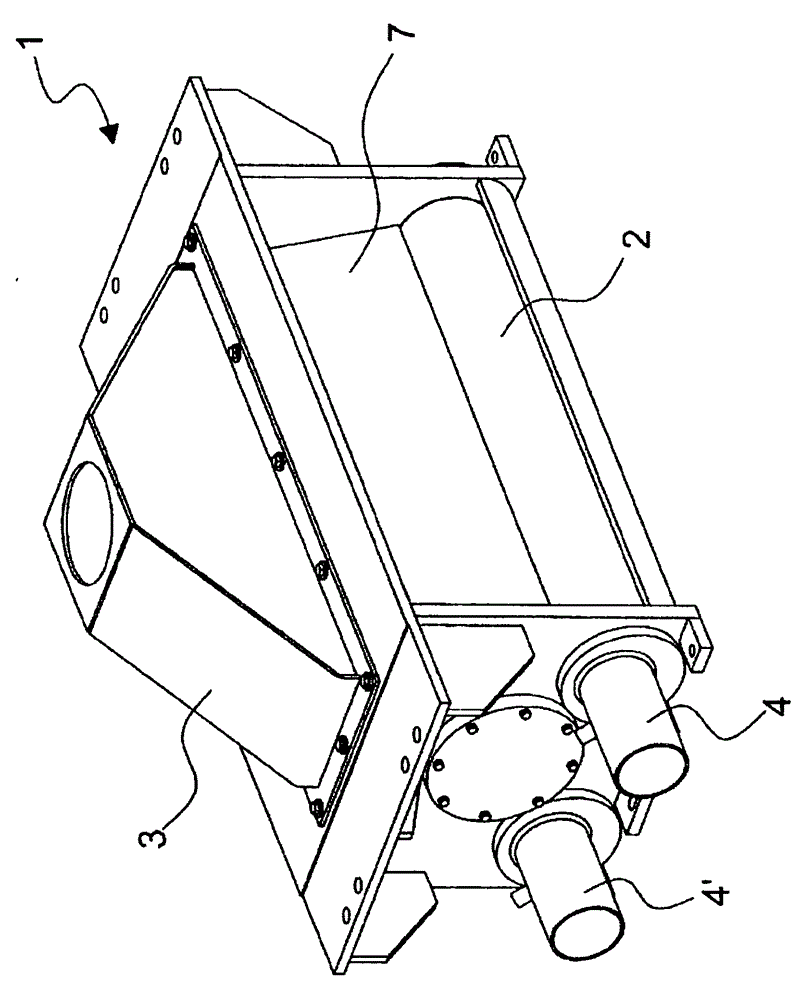

[0047] The apparatus of the present invention for removing liquid or solid particles from metal strips comprises:

[0048] - Conveyor means for providing an air jet or air knife onto said strip as it is being conveyed, to remove emulsifiable concentrate or other liquid and / or solid particles deposited on said strip;

[0049] - air extraction equipment;

[0050] - a housing, for example in the form of a tube bell, containing said conveying means and communicating with said suction means for sucking air containing removed atomized emulsion and / or lifted solid particles.

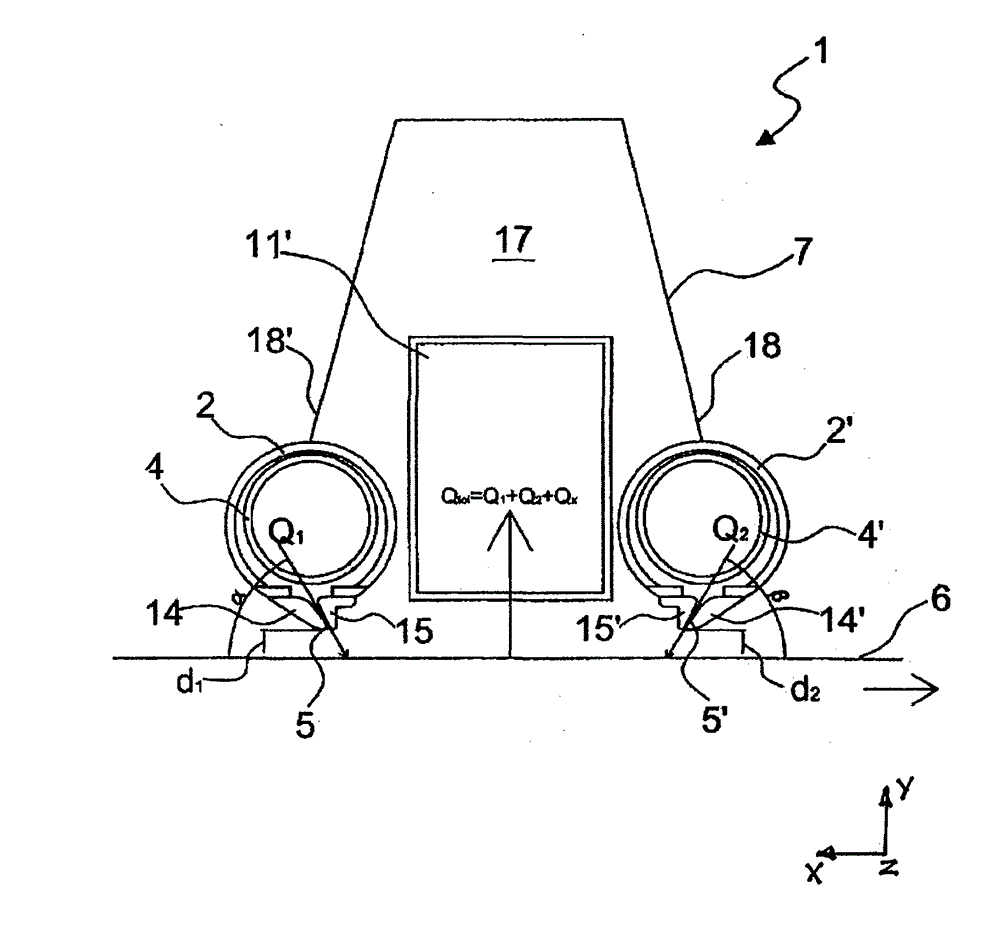

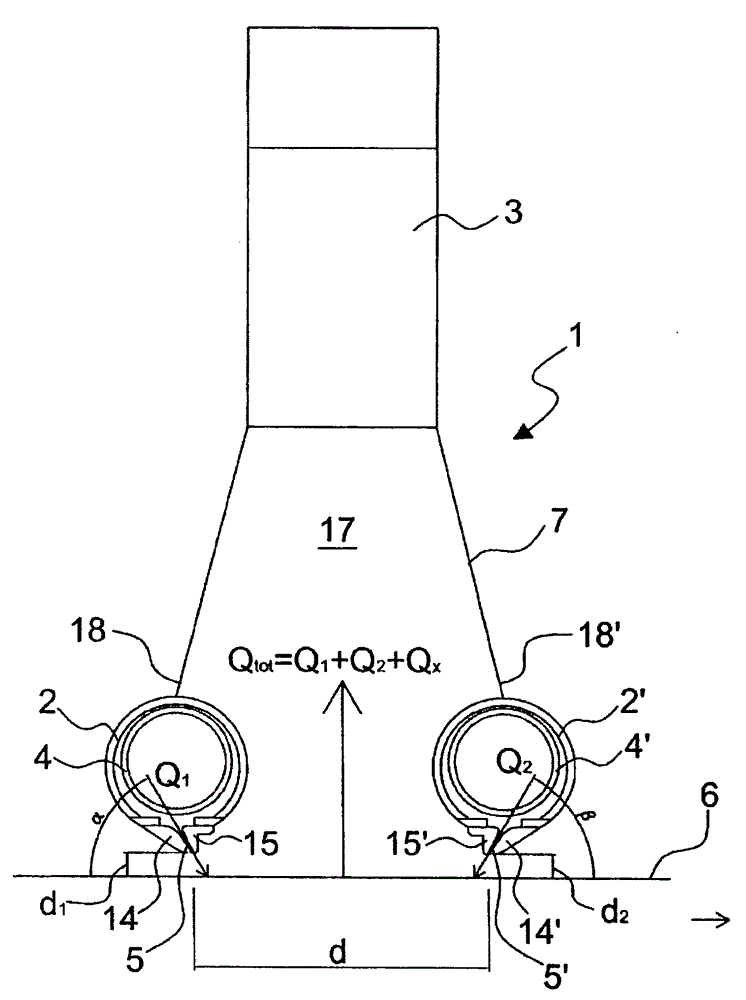

[0051] figure 1 with 2 A first embodiment of the device is shown, generally numbered 1 .

[0052] Said conveying means comprise two conveying or conveying collectors 2, 2' provided with conveying pipes 4, 4' respectively located on one side of said apparatus.

[0053] In its part closest to the conveying direction of the strip 6, the conveying collector 2, 2' is provided with two separate parts 14, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com