Illumination system for a microlithographic projection exposure apparatus

A lighting system and microlithography technology, applied in the field of lighting systems, can solve problems such as adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Lighting system

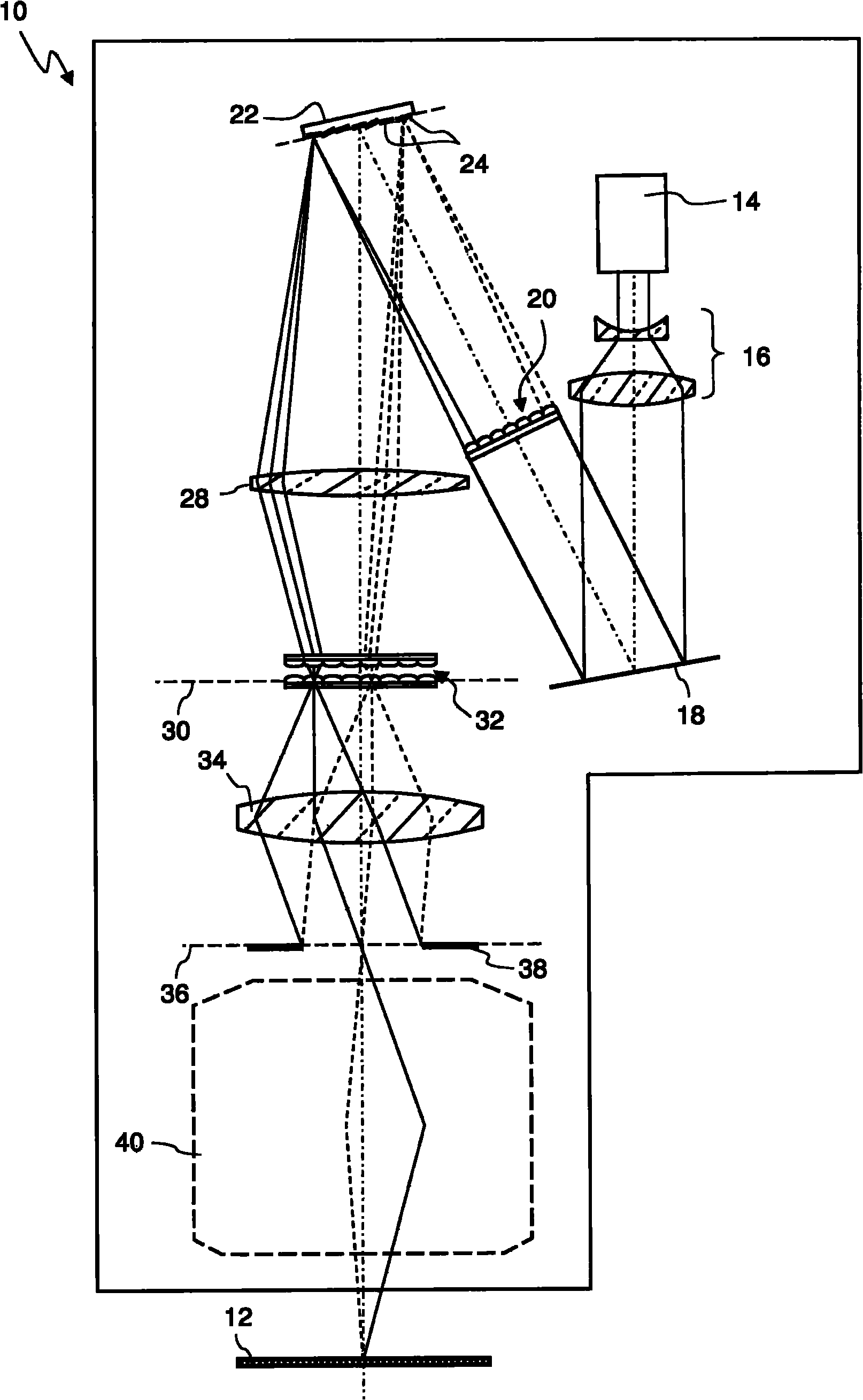

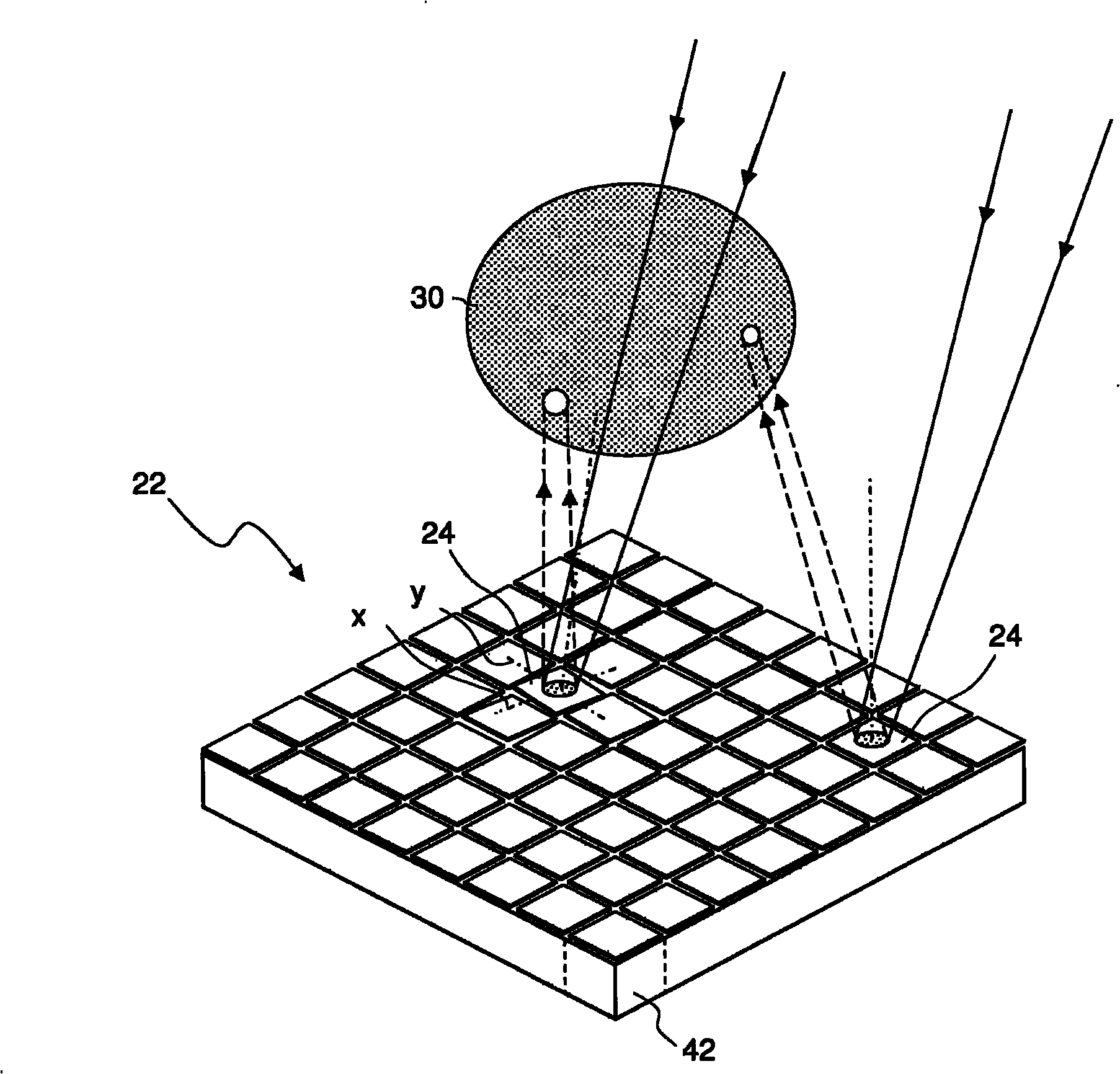

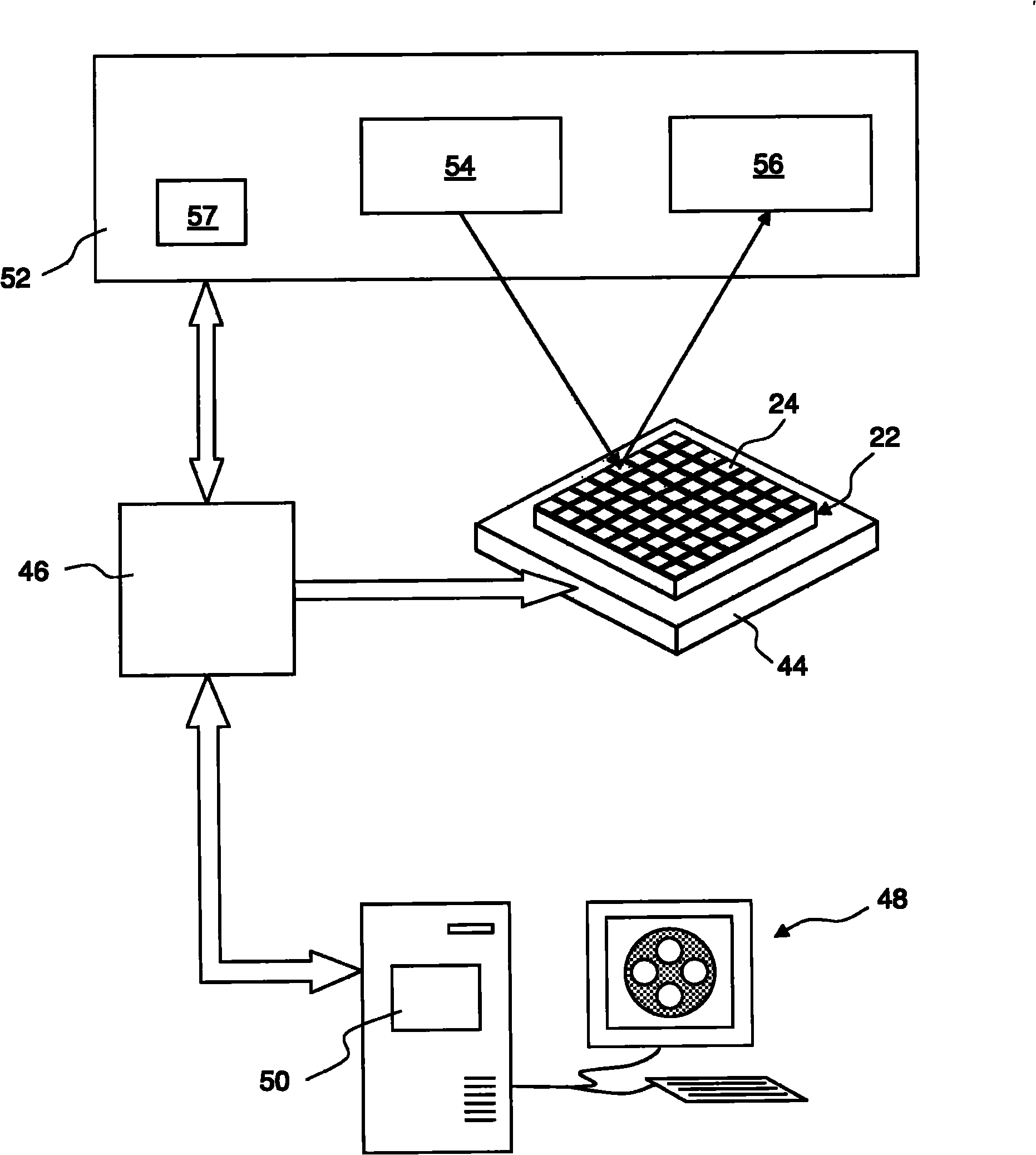

[0053] figure 1 A very simplified meridional cross-section of an illumination system 10 of a projection exposure apparatus for microlithography is shown. The illumination system 10 is used to illuminate with projected light a mask 12 carrying a lithographic structure to be imaged. A projection objective (not shown) then projects the illuminated structures onto the photoresist-coated wafer, typically in reduced size.

[0054] An important factor that decisively influences the imaging properties of a projection exposure system for microlithography is the angular distribution of the projection light. This is understood to mean the distribution of the total intensity of the light impinging on a mask spot which strikes it at different angles of incidence. In particular, it is desirable that the angular distribution of the projected light be adapted to the type of structure to be illuminated in order to obtain the best possible imaging.

[0055] For this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com