Technique for processing cigarette with low NAB release

A technology of processing technology and release rate, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problem of reducing NAB release amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

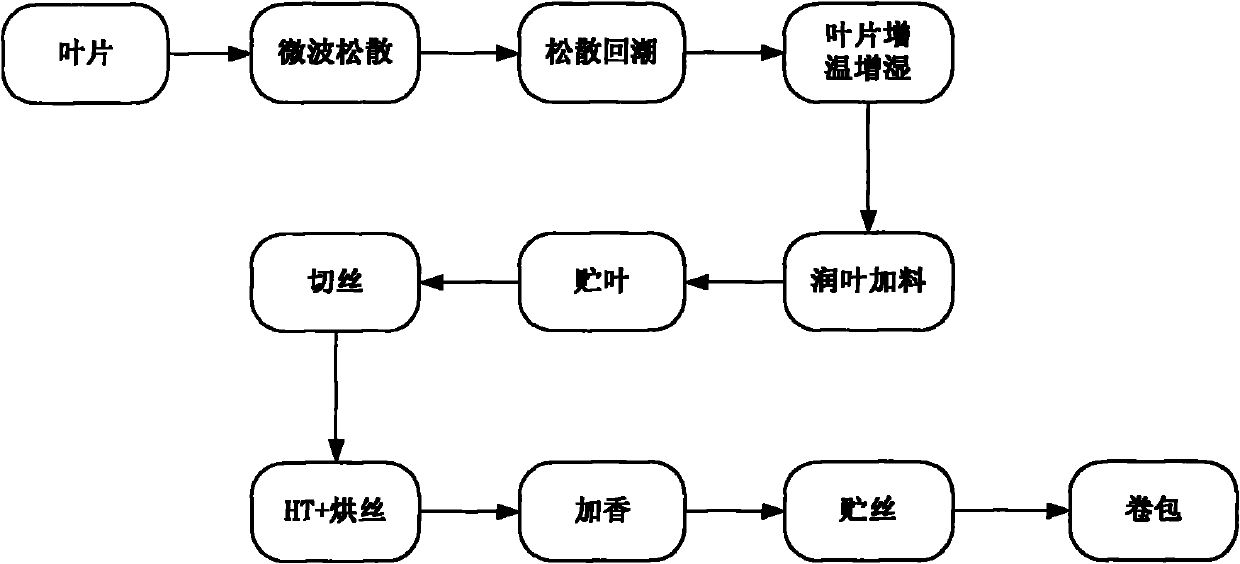

Method used

Image

Examples

Embodiment 1

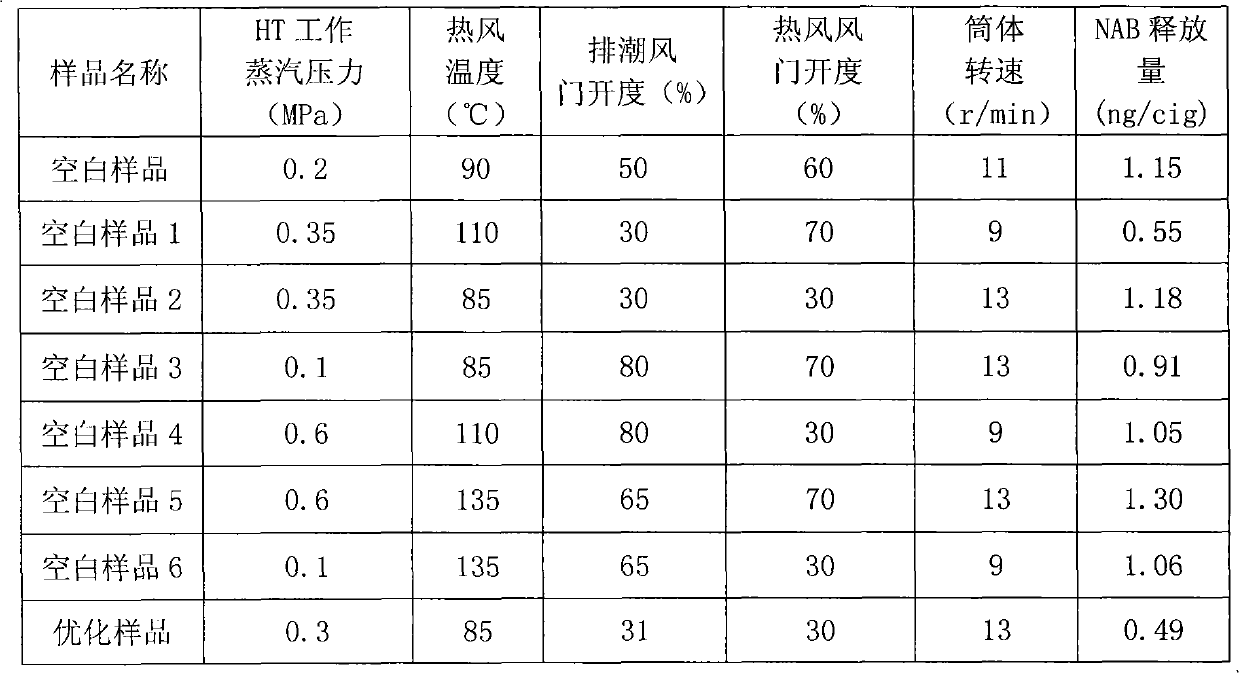

[0015] In the microwave loosening process of the silk making process, the process parameters of the microwave loosening process of the key backbone brand cigarettes are used as the benchmark process parameters, and the tobacco shreds are carried out based on the benchmark process parameters, and the tobacco samples produced are blank samples; The tobacco sample is an optimized sample, and the results are as follows:

[0016] Table 1 The release amount of NAB of samples in the microwave loosening process

[0017] sample name

[0018] It can be seen from Table 1 that the release of NAB in the flue gas of the tobacco samples produced under the optimized combination of microwave loosening process parameters was 53.91% lower than that of the blank sample; the amount of NAB in the flue gas of the samples produced under the optimized process parameters release was significantly reduced.

Embodiment 2

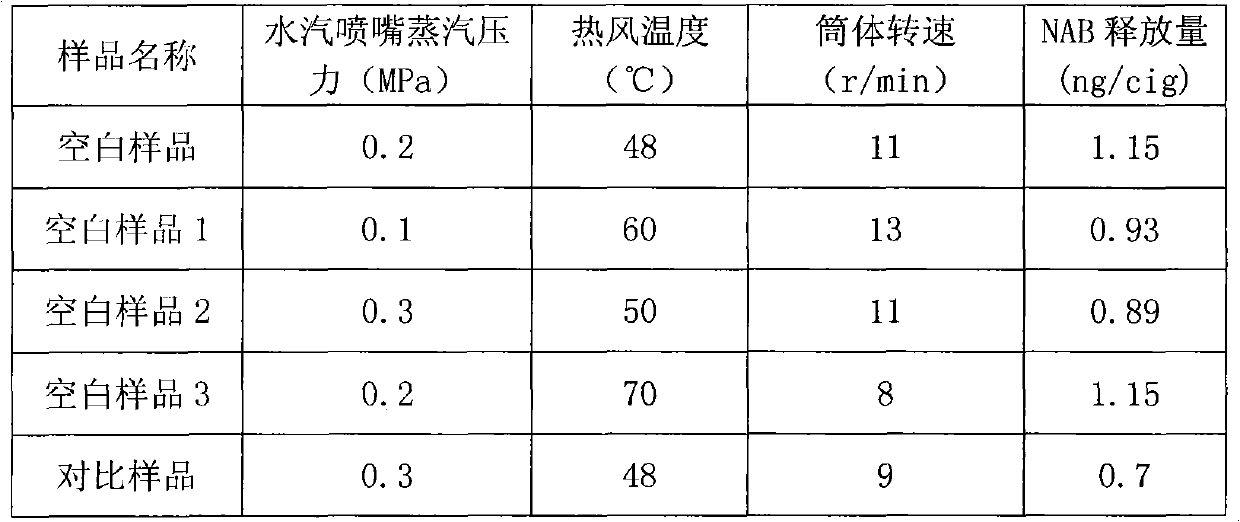

[0020] In the loosening and regaining process of the silk making process, the process parameters of the loosening and regaining process of the key backbone brand cigarettes are used as the benchmark process parameters, and the tobacco shreds are carried out based on the benchmark process parameters, and the tobacco samples produced are blank samples; The tobacco sample is an optimized sample, and the results are as follows:

[0021] Table 2 NAB release amount of tobacco samples in the loosening and rehydration process

[0022]

[0023] It can be seen from Table 2 that the release of NAB in the tobacco samples produced under the optimized combination of loose moisture regain process parameters is 39.13% lower than that of the blank sample, and the release of NAB in the smoke of the samples produced under the optimized process parameters volume decreased significantly.

Embodiment 3

[0025] In the HT+shredding process of the silk making process, the HT+shredded drying process process parameters of the key backbone brand cigarettes are used as the benchmark process parameters, and the tobacco shreds are carried out based on this benchmark process parameter, and the tobacco sample produced is a blank sample; according to the optimized parameters in step 3 The produced tobacco samples are optimized samples, and the results are as follows:

[0026] Table 3 NAB release amount of tobacco samples in HT+drying process

[0027]

[0028] It can be seen from Table 3 that the release of NAB in the flue gas of the tobacco samples produced under the optimized combination of HT+drying process parameters was 57.39% lower than that of the blank sample; The release of NAB was significantly reduced.

[0029] In this paper, the vapor pressure is gauge pressure.

[0030] The release of NAB from the sample was tested according to the standard GB / T 23228-2008, and its Chine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com