Porous biodegradable composite-type bone repairing material and preparation method thereof

A biodegradable and biodegradable technology, applied in the field of porous biodegradable composite bone repair materials and production, can solve the problem of slow biodegradation of hard block materials, prolonged waiting period for implant implantation, and inability of materials. Formation of biological binding and other issues to achieve the effect of easy storage and transportation, easy access, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

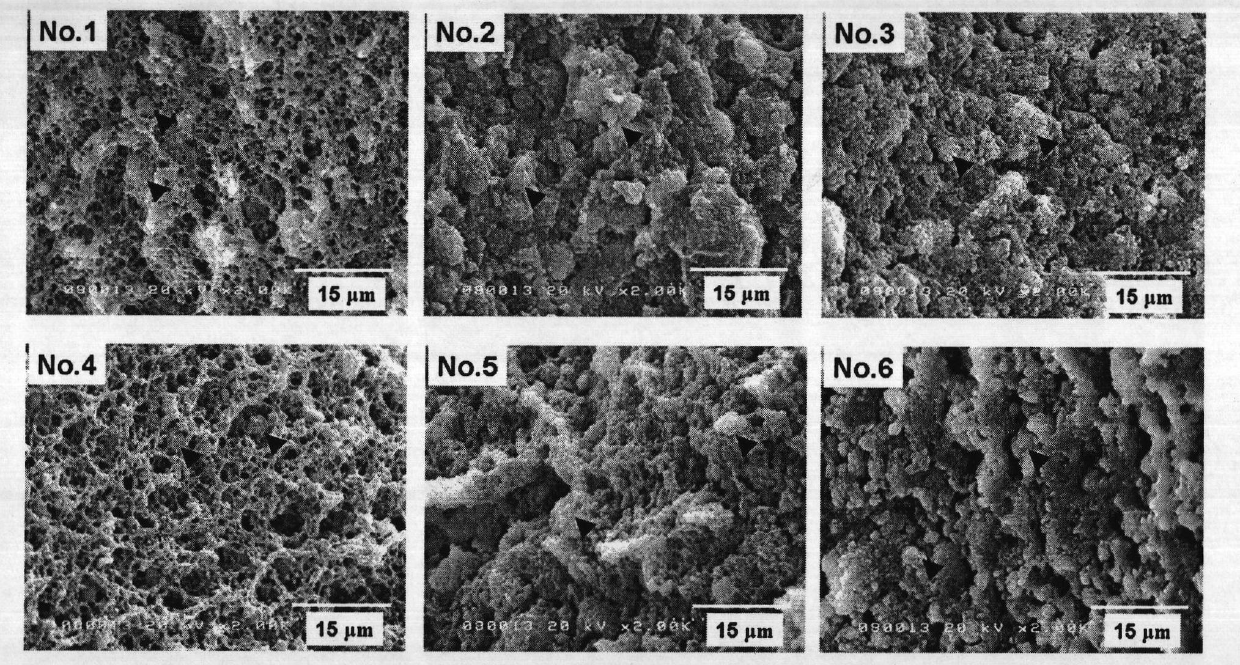

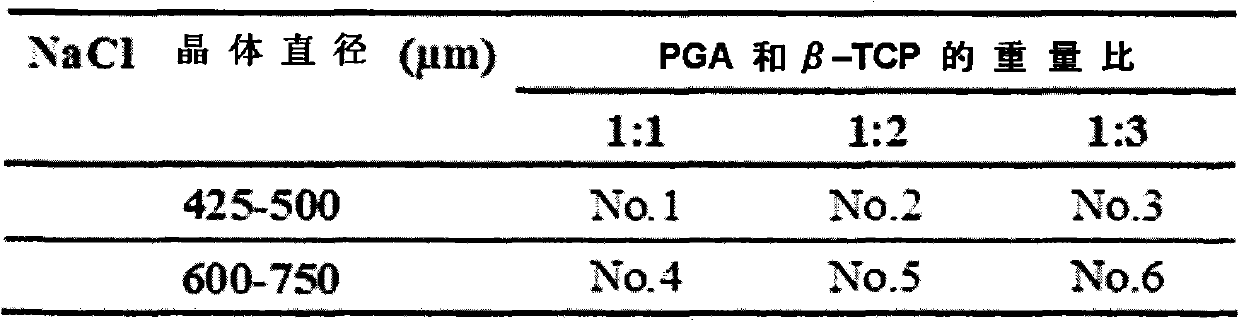

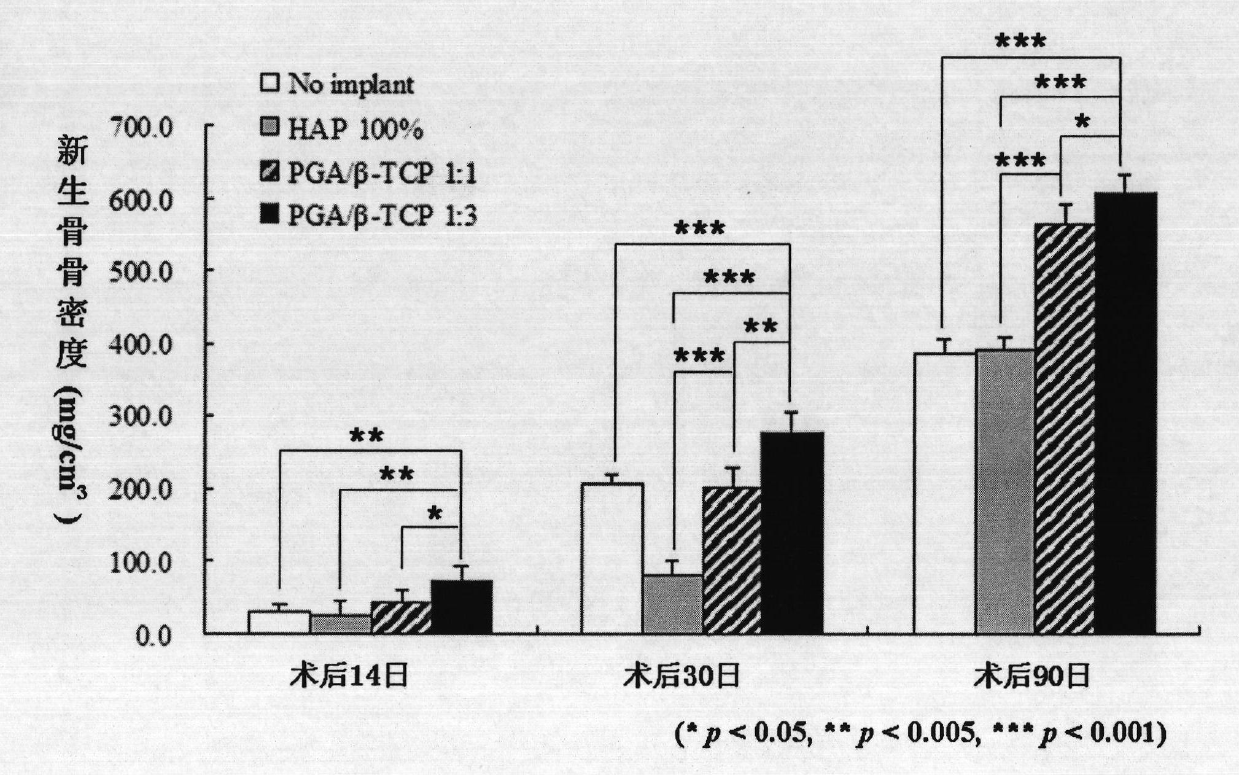

Embodiment 1

[0037] At room temperature, the polyglycolic acid PGA is completely dissolved in the organic solvent HFIP at a concentration of 0.2 g / ml (PGA / HFIP) to form a polyglycolic acid PGA solution. Add β-tricalcium phosphate β-TCP powder into polyglycolic acid PGA solution (the weight ratio of PGA and β-TCP is 1:1), shake and mix until there is uniform fluidity, and obtain PGA / β-TCP containing a large number of microbubbles. TCP suspension. Fill the suspension into the glass mold, and then quickly add a certain amount of sodium chloride crystals (particle size range: 425-500 μm) until the sodium chloride crystals no longer settle and fill the mold. At room temperature (25°C), condensation (24 hours), solvent volatilization (48 hours), sodium chloride crystal filtration (72 hours, replace distilled water every 12 hours), high temperature and high pressure steam sterilization (gradually increase the temperature to 126 ℃, constant temperature for 40 minutes, and then gradually lowered t...

Embodiment 2

[0047] At room temperature, the polyglycolic acid PGA is completely dissolved in the organic solvent HFIP at a concentration of 0.2 g / ml (PGA / HFIP) to form a polyglycolic acid PGA solution. Add β-tricalcium phosphate β-TCP powder into polyglycolic acid PGA solution (the weight ratio of PGA and β-TCP is 1:3), shake and mix until there is uniform fluidity, and obtain PGA / β-TCP containing a large number of microbubbles. TCP suspension. Fill the suspension into the glass mold, and then quickly add a certain amount of sodium chloride crystals (particle size range: 425-500 μm) until the sodium chloride crystals no longer settle and fill the mold. At room temperature (25°C), condensation (24 hours), solvent volatilization (48 hours), sodium chloride crystal filtration (72 hours, replace distilled water every 12 hours), high temperature and high pressure steam sterilization (gradually increase the temperature to 126 ℃, constant temperature for 40 minutes, and then gradually lowered t...

Embodiment 3

[0058] At room temperature, the polyglycolic acid PGA is completely dissolved in the organic solvent HFIP at a concentration of 0.2 g / ml (PGA / HFIP) to form a polyglycolic acid PGA solution. Add β-tricalcium phosphate β-TCP powder into polyglycolic acid PGA solution, the weight ratio of PGA and β-TCP is 1:2, shake and mix until there is uniform fluidity, and obtain PGA / β-TCP containing a large number of microbubbles suspension. Fill the suspension into the glass mold, and then quickly add a certain amount of sodium chloride crystals (particle size range: 425-500 μm) until the sodium chloride crystals no longer settle and fill the mold. At room temperature (25°C), condensation (24 hours), solvent volatilization (48 hours), sodium chloride crystal filtration (72 hours, replace distilled water every 12 hours), high temperature and high pressure steam sterilization (gradually increase the temperature to 126 ℃, constant temperature for 40 minutes, and then gradually lowered to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap