Automatic diamond synthesized column core assembling machine

A technology of diamond synthesis column and automatic assembly machine, which is applied in the application of ultra-high pressure process, etc., can solve the problems of large assembly error of diamond synthesis column core, labor, material and time consumption, and low quality of synthetic diamond, so as to meet the requirements of the work Need, reduce labor intensity, reduce the effect of harm to the human body

Active Publication Date: 2011-01-19

郑州华晶新能源科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a long time, the assembly work of the diamond composite core has been completely done manually, which not only consumes a lot of manpower, material resources and time, but also has low work efficiency, high breakage rate of the insulating bowl, and large assembly errors in the diamond composite core. Leads to low quality synthetic diamonds

In addition, the first process of assembling the diamond synthetic column core is to install the graphite column, that is, install two insulating bowls of the same size from both ends of the graphite column, so that the outer diameter of the graphite column and the inner diameter of the insulating bowl are closely matched. Stop rotating and pushing the insulating bowl, the graphite column and the insulating bowl powder that are worn off during the rotation are scattered into the air, which is extremely harmful to the human respiratory tract

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

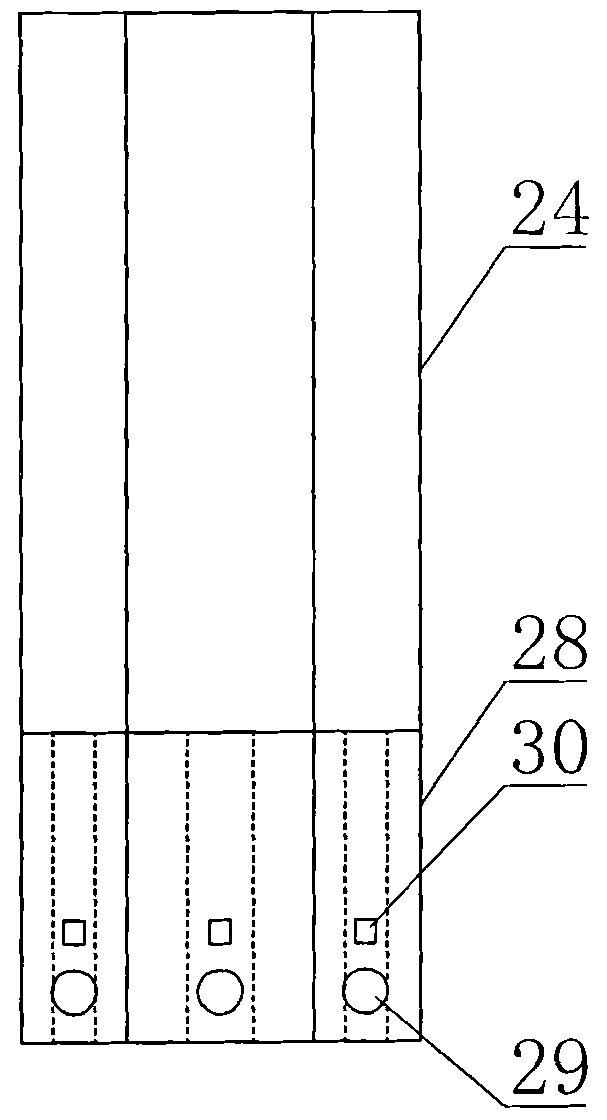

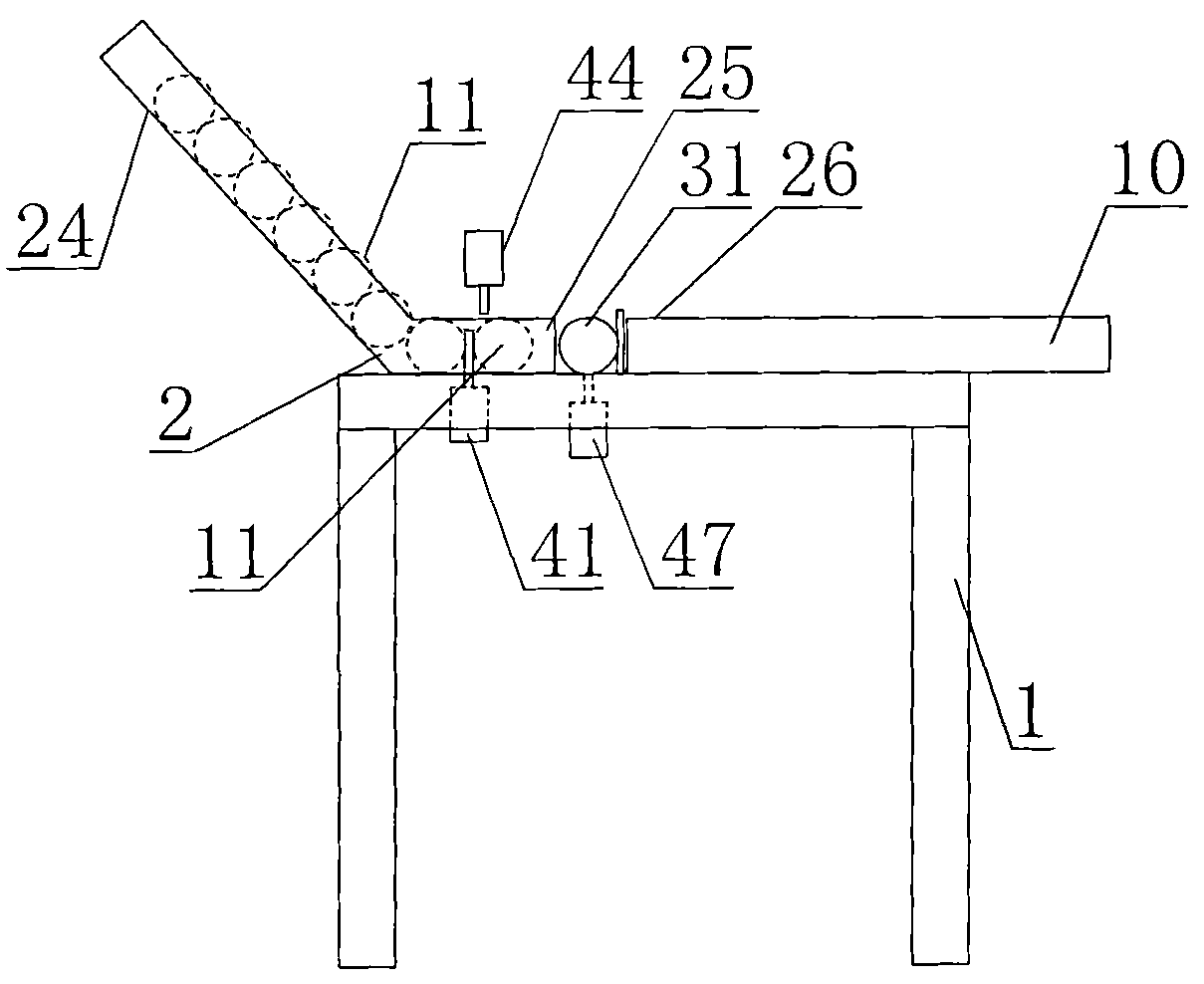

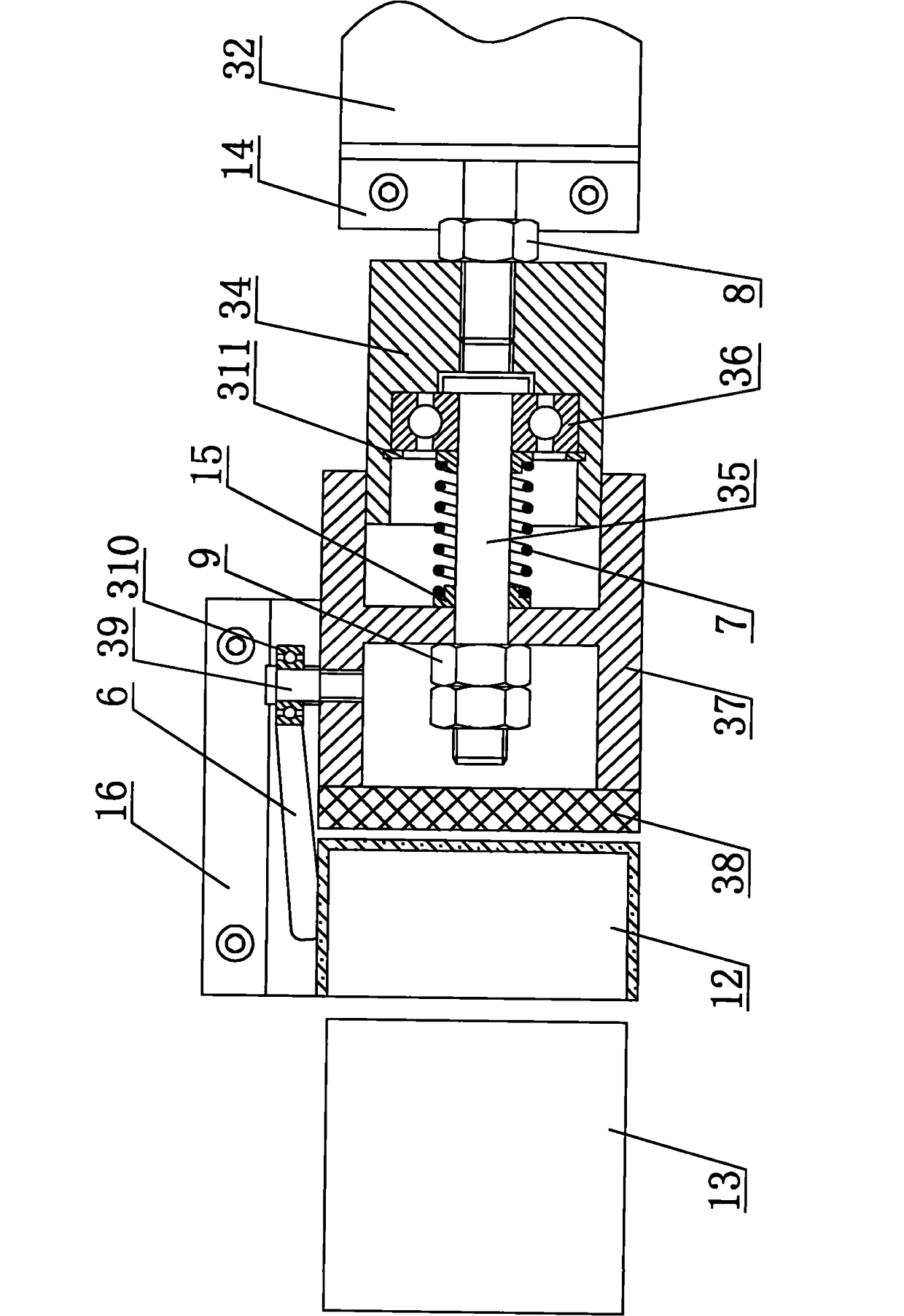

The invention discloses an automatic diamond synthesized column core assembling machine, which comprises a base, an automatic loading device arranged on the base, and a rotary propelling device arranged at the discharge hole of the automatic loading device; and the automatic loading device and the rotary propelling device are connected with a pneumatic power system. The automatic mechanical assembly replaces the manual assembly, so the work efficiency is improved, the harm to a human body is reduced, the labor intensity is reduced, the fault rate of fittings is reduced and the production cost is reduced.

Description

technical field The invention belongs to the technical field of superhard material synthesis equipment, in particular to an automatic assembly machine for diamond synthesis column cores. Background technique In the field of superhard material synthesis, taking synthetic diamond as an example, the synthesis principle is: diamond and graphite are allotropes, and the diamond synthesis column core is put into the synthesis chamber formed by the six-sided top press, and heated at 1500 ° C and 5.5 Under the Gpa high pressure condition, the diamond synthetic column core is transformed into diamond. The diamond synthetic column core is a cylinder with a certain diameter and height, which is assembled in some way from graphite columns, pyrophyllite blocks and conductive steel rings. For a long time, the assembly work of the diamond composite core has been completely done manually, which not only consumes a lot of manpower, material resources and time, but also has low work efficienc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J3/06

Inventor 林玉申兆清王振海彭献伟

Owner 郑州华晶新能源科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com