Grinding wheel corrector

A grinding wheel correction and longitudinal technology, which is applied to abrasive surface adjustment devices, parts of grinding machine tools, metal processing equipment, etc. The method is flexible and changeable, the correction efficiency is high, and it is easy to process the effect of the feed rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

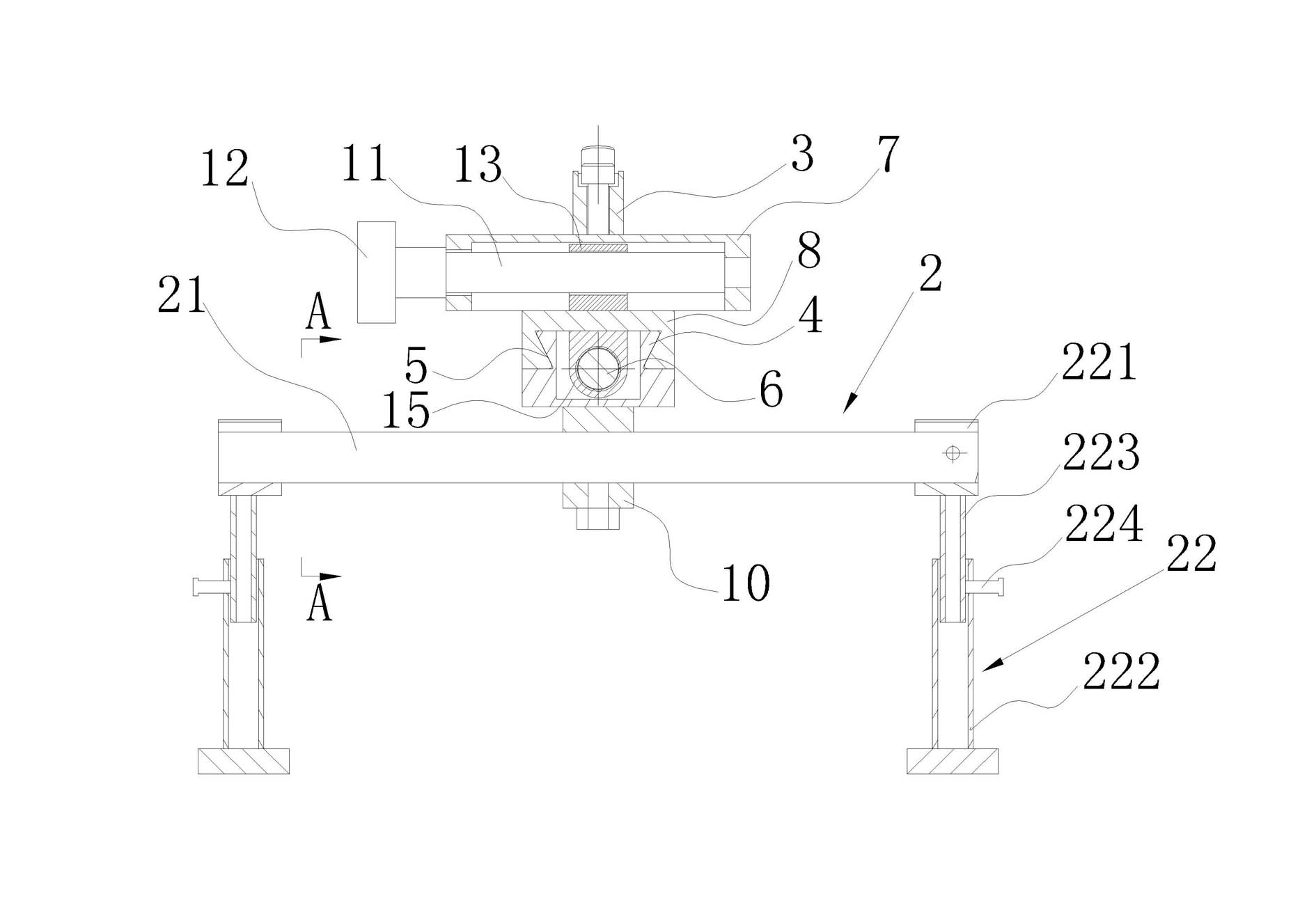

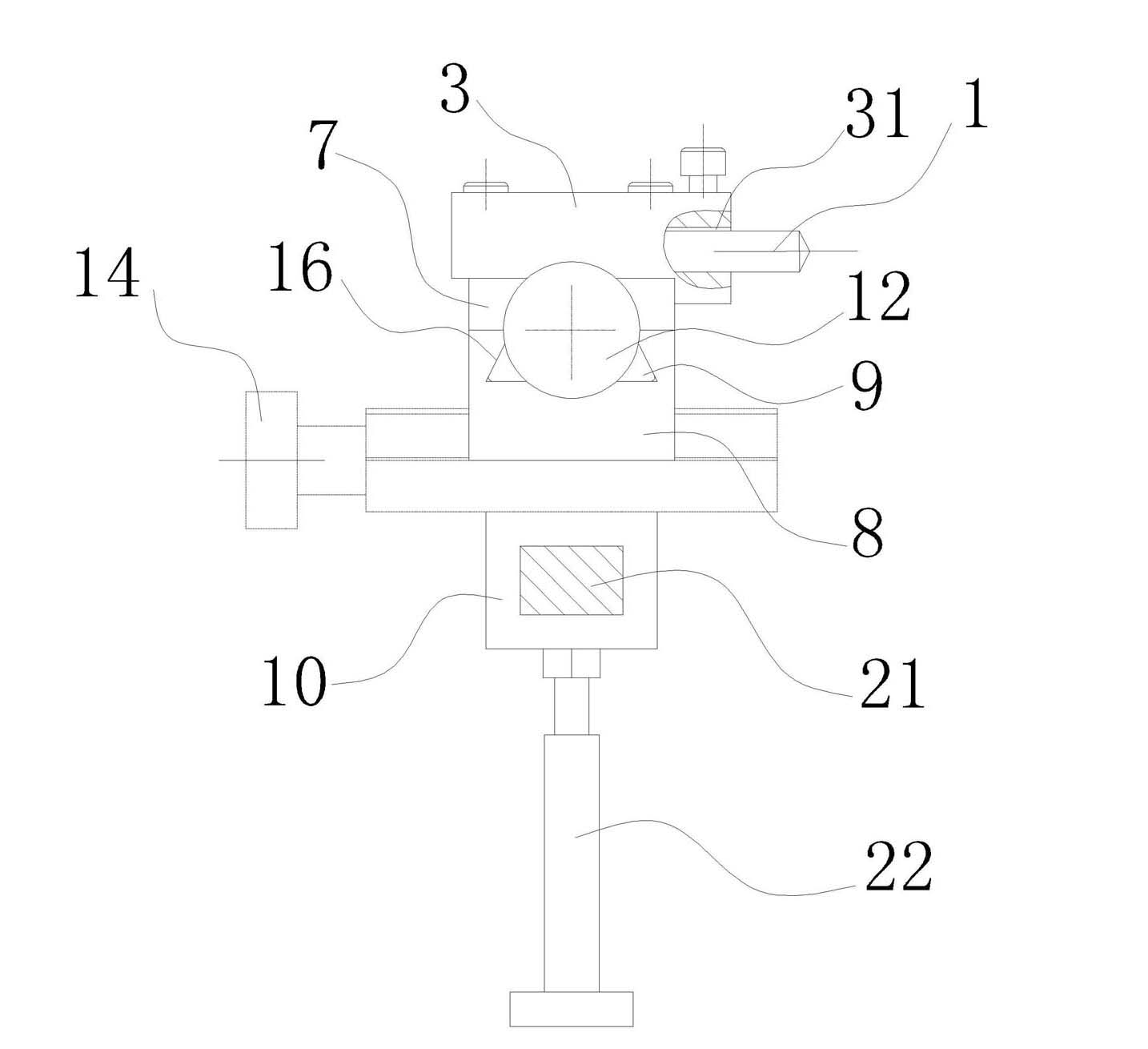

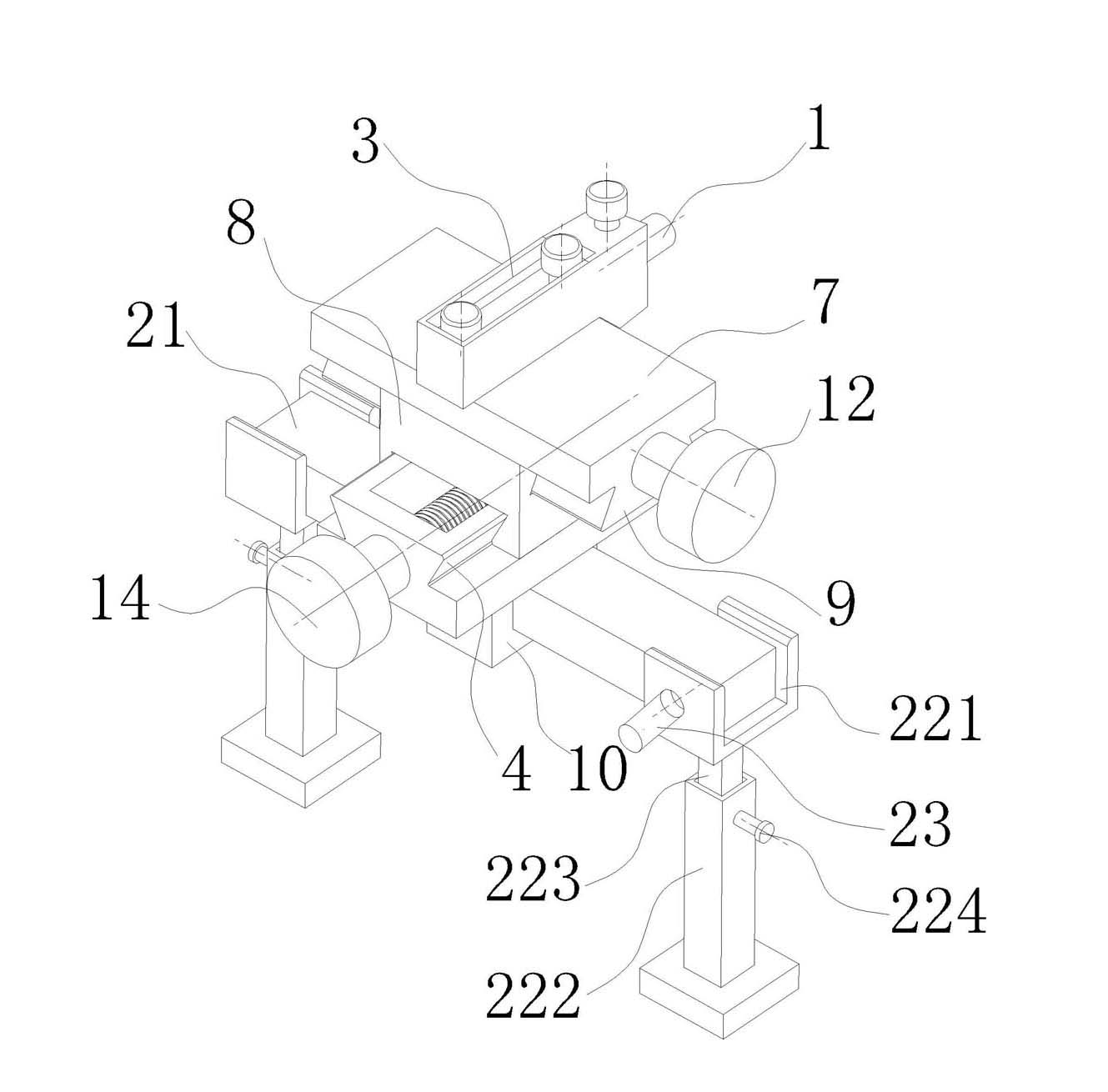

[0022] Such as figure 1 As shown, in a kind of grinding wheel corrector of the present invention, comprise support 2 and the tool rest 3 that can slide horizontally along the support beam 21 of square tube structure on the support 2, be provided with again between support beam 21 and tool rest 3 The longitudinal dovetail slide rail boss 4 and the longitudinal dovetail slide rail groove 5 that cooperate with each other, the longitudinal dovetail slide rail boss 4 is slidably connected in the longitudinal dovetail slide rail groove 5 through the drive of the longitudinal screw rod 6 and drives the tool holder 3 along the bracket 2 vertical and horizontal swipe. The support 2 includes a horizontally arranged support beam 21 and a support longitudinal beam 22 symmetrically supported at both ends of the support beam 21, wherein the support longitudinal beam 22 includes a lower support tube 222 of the longitudinal beam of a square tube structure and an upper support tube 223 of the...

Embodiment 2

[0025] One end of the horizontal screw rod 11 extends outwards and is connected with the horizontal translation motor through the reducer, and one end of the longitudinal screw rod 6 extends outwards and is connected with the longitudinal translation motor through the reducer. All the other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com