New energy storage inductor and manufacturing method thereof

An energy storage inductance, new energy technology, applied in the direction of inductance/transformer/magnet manufacturing, inductors, fixed inductors, etc., can solve the limited application range of ferrite energy storage inductors, difficult inverter high efficiency requirements, conversion Low efficiency and other problems, to achieve the effect of improving the number of coils and space, compact mechanism and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

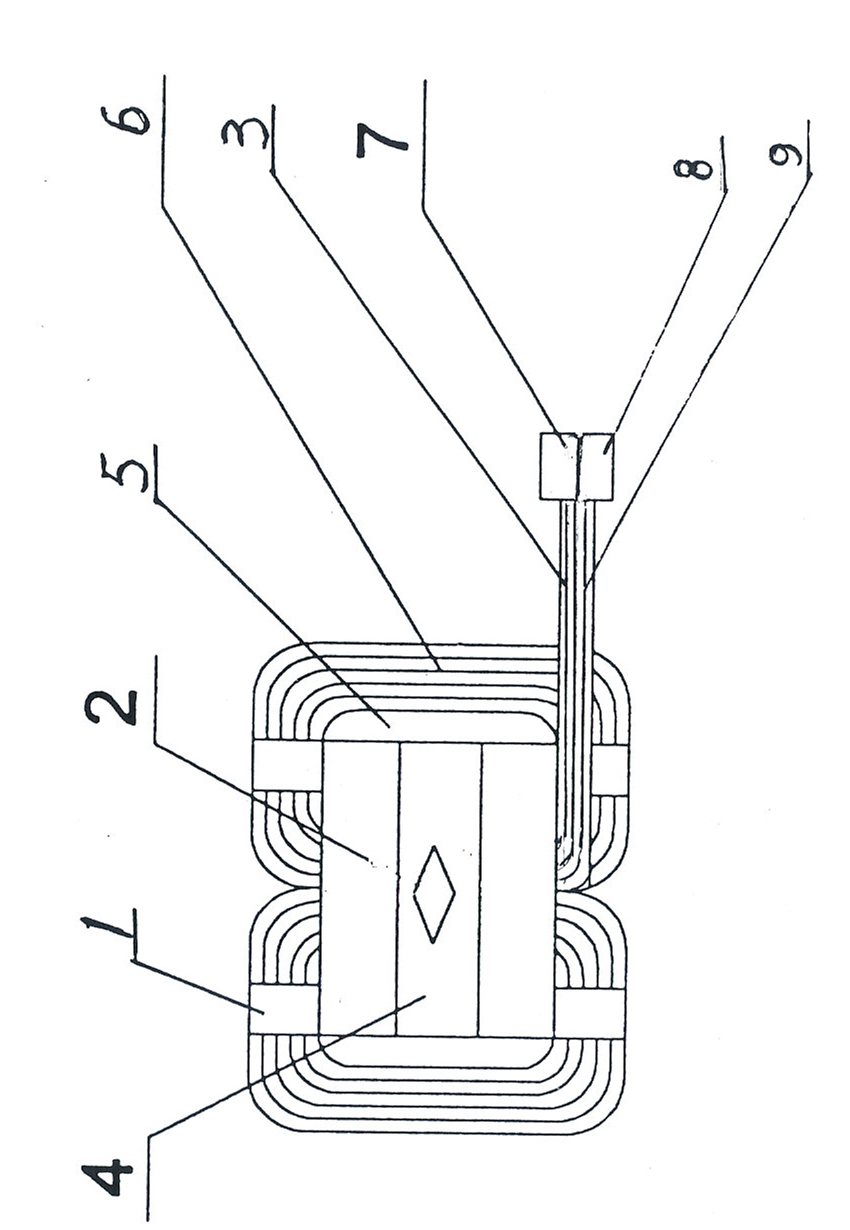

[0019] Refer to attached figure 1 , The new energy storage inductor includes a magnetic core 2, a wire package 6, an insulating sleeve 5, an insulating gasket, a lead wire 3, a terminal 7, a fixing clip 4 and insulating varnish. Two wire packs 6 are set on the magnetic core 2, an insulating sleeve 5 is installed between the magnetic core 2 and the wire pack 6, and an insulating gasket is installed between the magnetic cores, and a fixed clip 4 is used to fix the magnetic core. core, two wire packs are welded with an electric soldering iron at the incoming wire end respectively, and have an incoming wire end lead-out line 3, and an incoming wire terminal 7 is installed at the lead-out wire port, and an electric soldering iron is used to weld the outgoing wire end of the two wire packs respectively with an outgoing wire end lead-out Line 9 is equipped with outlet terminal 8 at the lead-out port, and wire package 6, magnetic core 2 and insulating cover 5 are all dipped in insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com