Three-dimensional structure microelectrode applied to mini-super capacitor and manufacturing method thereof

A supercapacitor, three-dimensional structure technology, applied in the field of MEMS, to achieve the effect of improving storage capacity, improving energy storage characteristics and high current discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

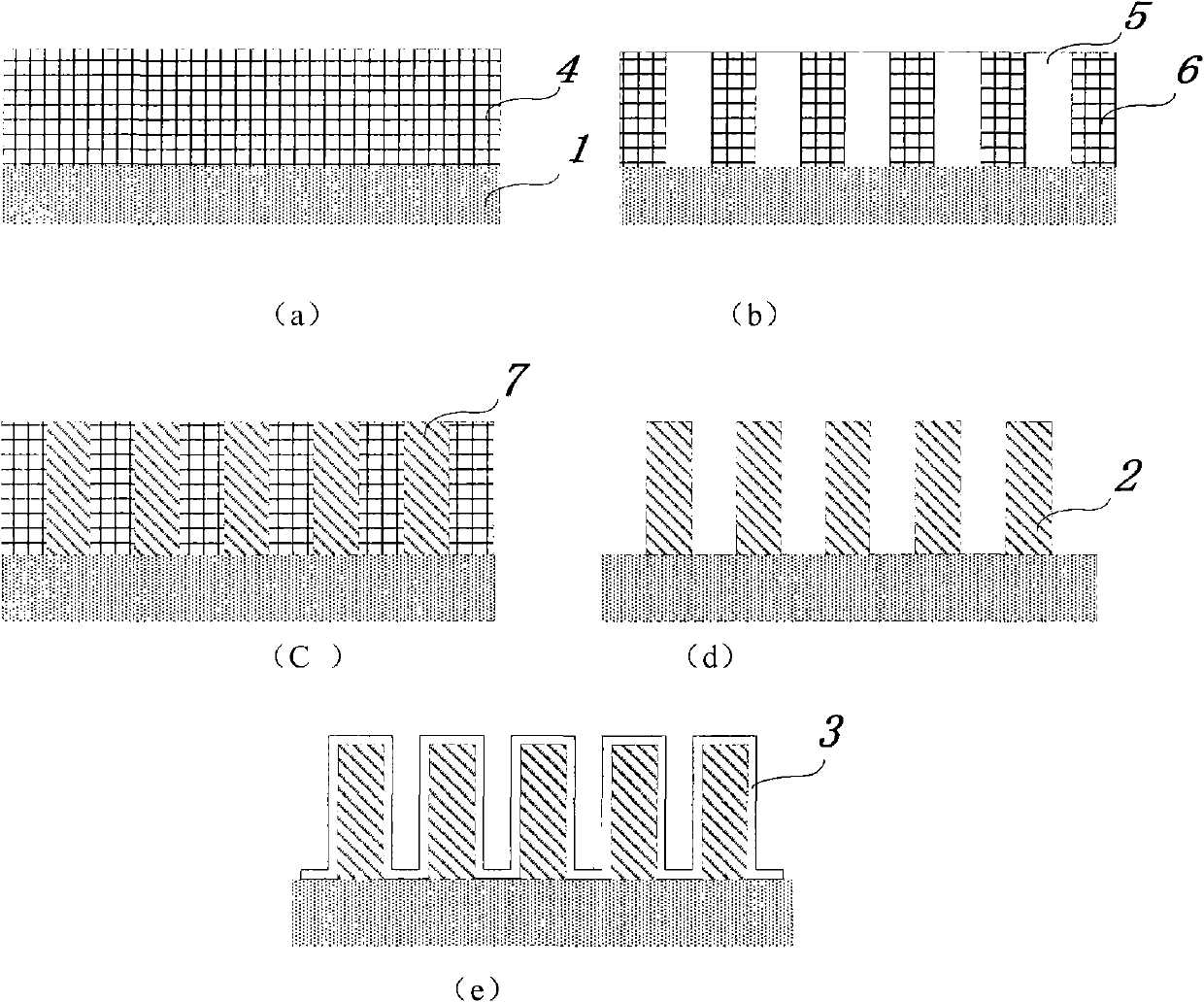

[0020] The invention provides a three-dimensional structure microelectrode applied to a micro supercapacitor and a manufacturing method thereof, which is based on MEMS technology and is proposed in view of the limited area of the two-dimensional structure microelectrode of the micro supercapacitor in the related art, which cannot meet the energy storage requirements of the device. Three-dimensional microelectrodes. The present invention will be described in detail below with reference to the accompanying drawings and examples.

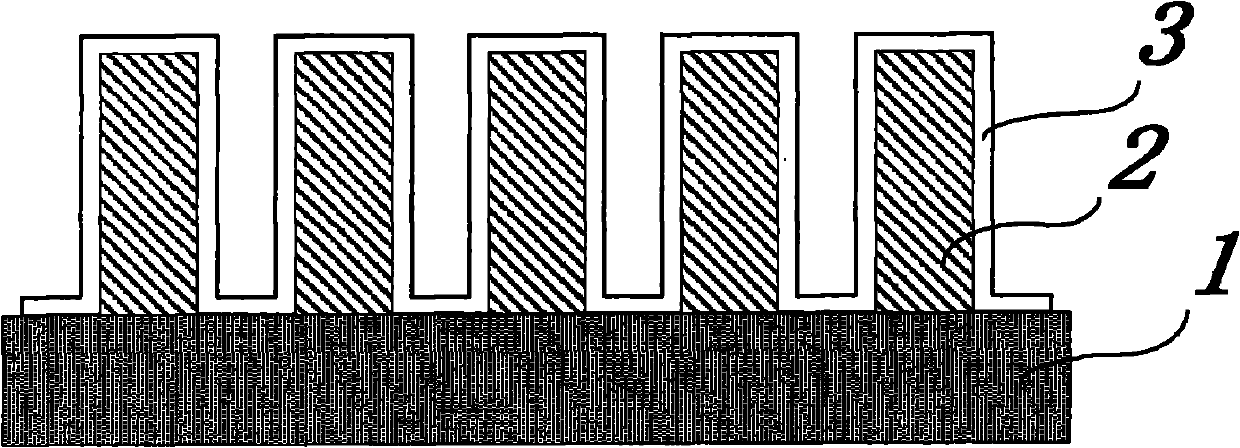

[0021] figure 1 It is a schematic diagram of the composition of the three-dimensional microelectrode. The three-dimensional structure microelectrode is to erect nickel microcolumn array 2 on one side of nickel substrate 1, and coat functional film 3 on the surface of nickel microcolumn 2. In the above-mentioned embodiment, by preparing on one side of metal substrate 1 The metal microcolumn array 2 forms a three-dimensional space structure with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com