Columnar capacitor, stacking-type coaxial columnar capacitor and preparation method thereof

A capacitor and columnar technology, applied in the field of capacitors, can solve the problems of increasing the circuit area and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

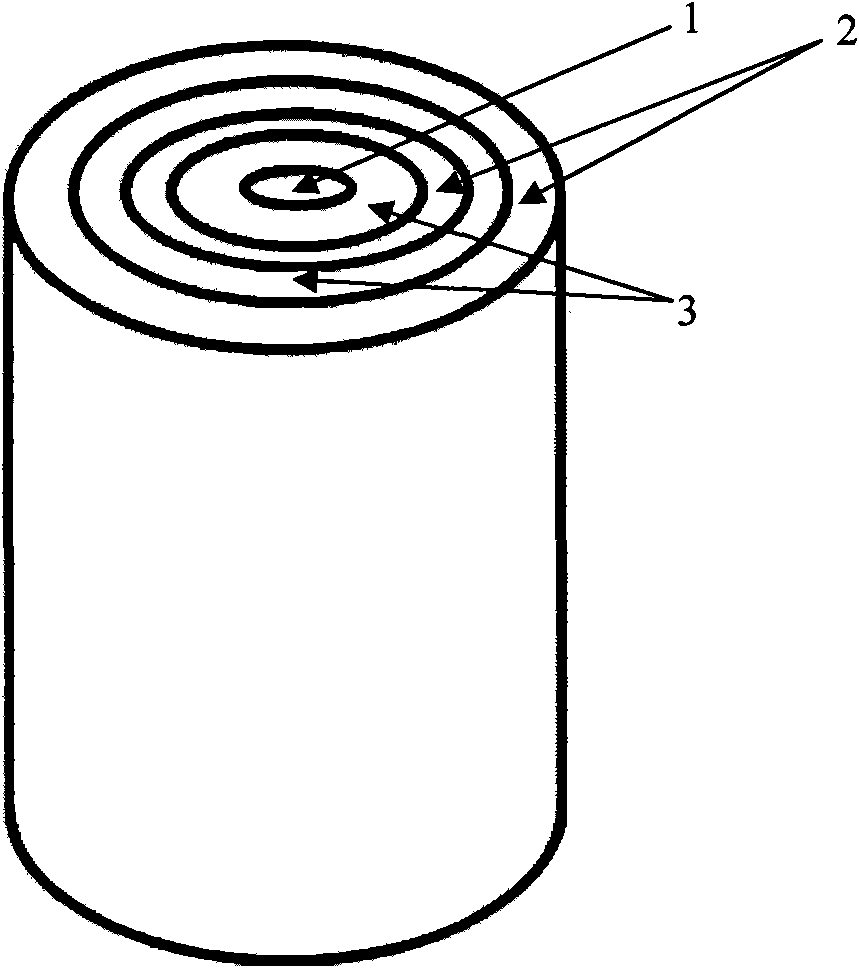

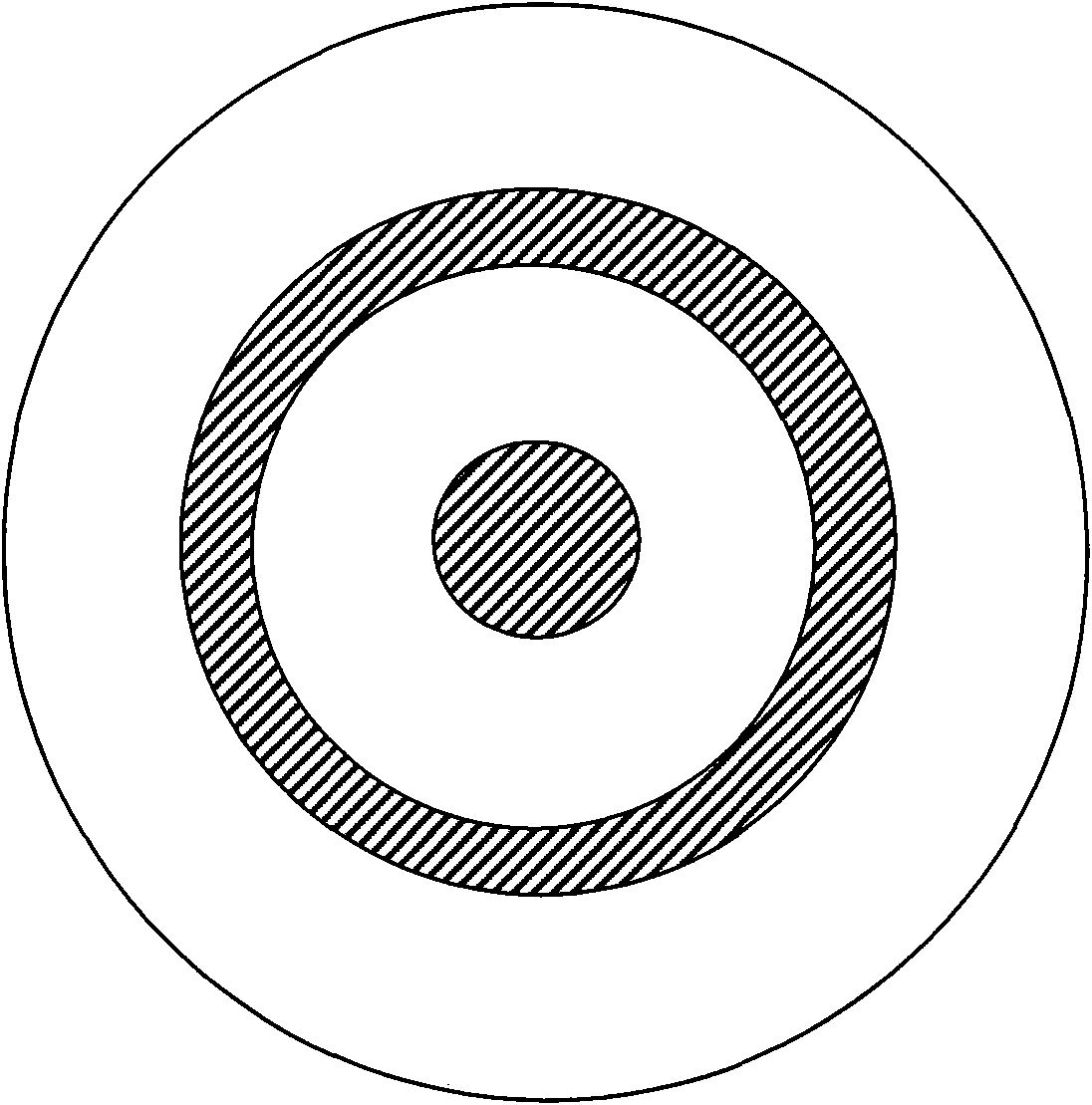

[0026] Such as figure 1 As shown, the columnar capacitor of the present invention is formed in the process of preparing through holes and connections between different metal layers. The columnar capacitor includes a dielectric layer 3, wherein a central through hole 1 and at least one through hole 1 connected to the center are provided. The coaxial annular columnar through-hole 2 , the central through-hole 1 and the annular columnar through-hole 2 are respectively filled with metal to form metal regions, and adjacent metal regions are not connected.

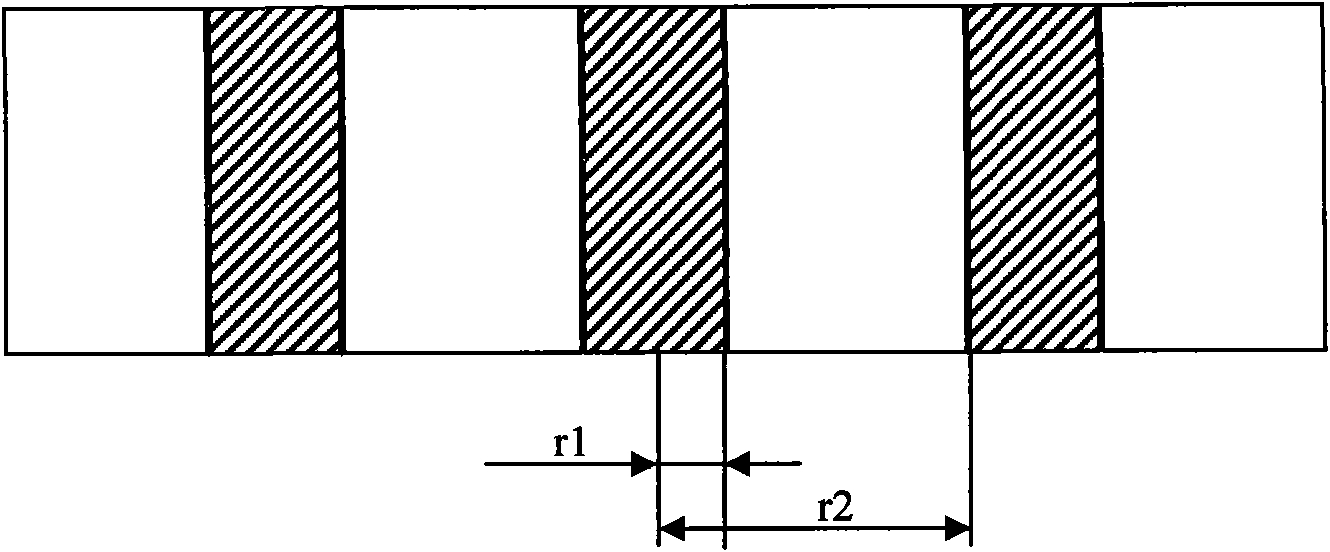

[0027] Please refer to figure 2 with image 3 , the preparation method of the above-mentioned coaxial columnar capacitor is implemented in the process of preparing through holes and wiring between different metal layers, including the following steps:

[0028] (1) Deposit a dielectric layer, and through exposure and development on the dielectric layer (the material of the dielectric layer can be an oxide, such as silicon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com