Conducting polymer modified super capacitor and manufacturing method thereof

A conductive polymer, supercapacitor technology, applied in electrolytic capacitors, capacitors, capacitor electrodes, etc., can solve problems such as single method and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments.

[0030] A preparation method for a supercapacitor modified by a conductive polymer, comprising the following steps:

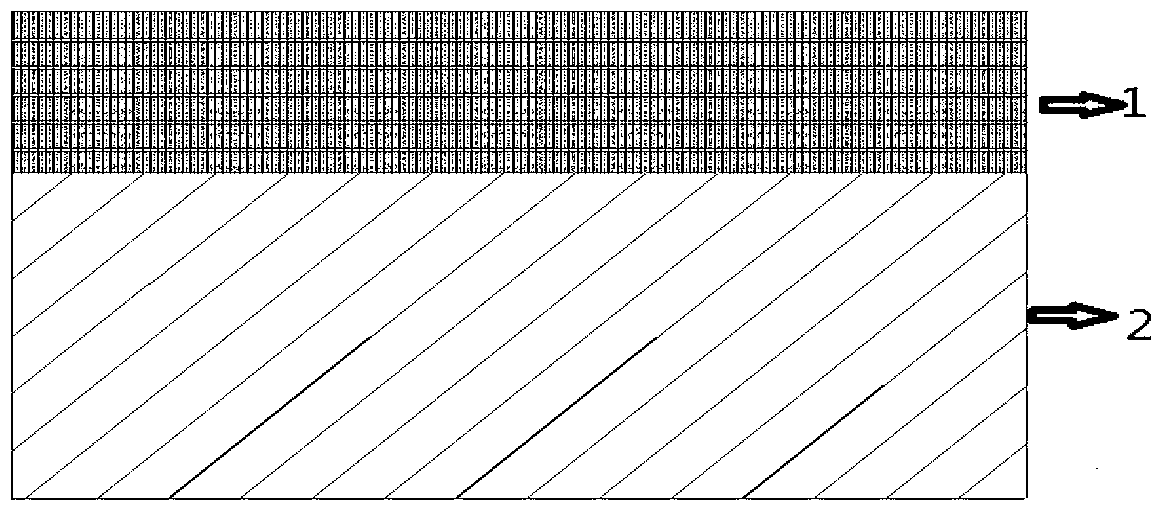

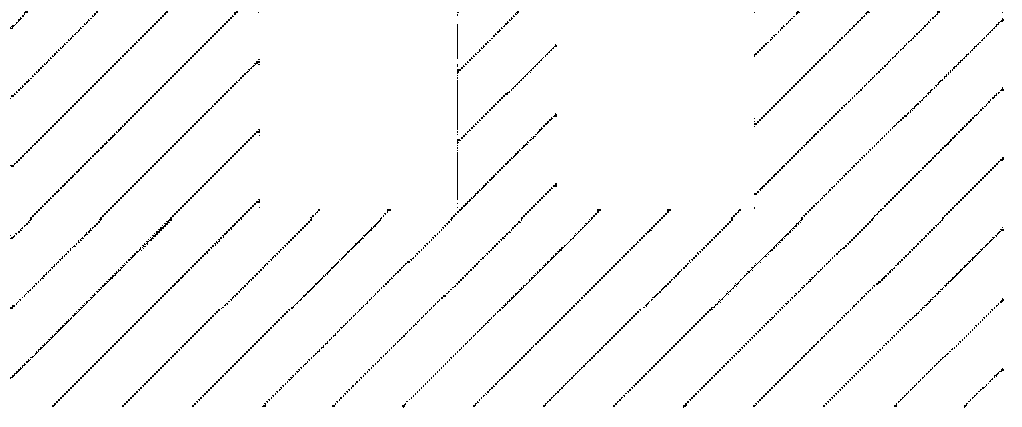

[0031] Step 1: Take two clean silicon substrates with the same shape and size, and coat them with a layer of silicon nitride (such as figure 1 shown), and then use photolithography to etch several pairs of micro-grooves in the same area on each silicon substrate, with the same isolation columns between each pair of micro-grooves (such as figure 2 shown).

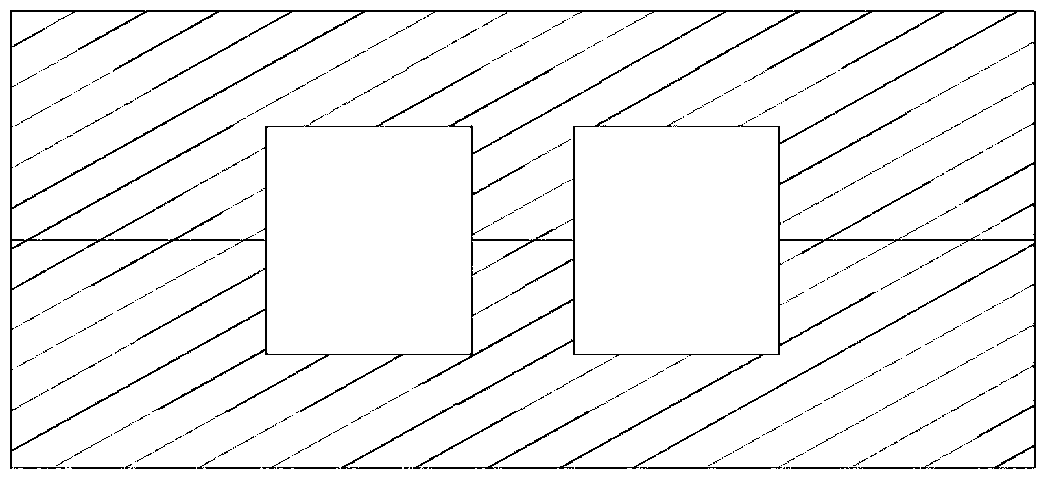

[0032] Step 2: Align the micro-grooves of two silicon substrates face to face, and bond them to obtain several pairs of micro-grooves enclosed in the silicon material (such as image 3 shown).

[0033] Step 3: Etch away the silicon material above the entire area corresponding to each pair of micro-grooves plus the isolation column between the pair of micro-grooves, so that the height of the isolation column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com