Suppressing fractures in diced integrated circuits

A technology for integrated circuits and dielectric layers, applied in the field of splitting IC dies, which can solve problems such as reduced adhesive strength, early failure of yield loss, and low dielectric rupture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

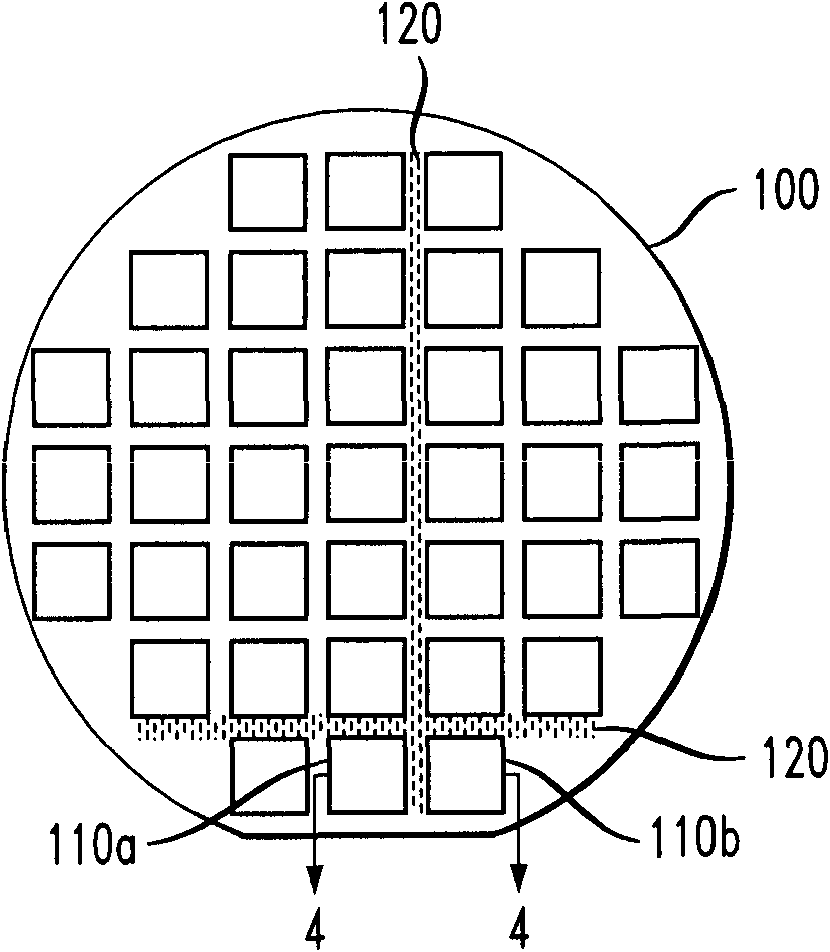

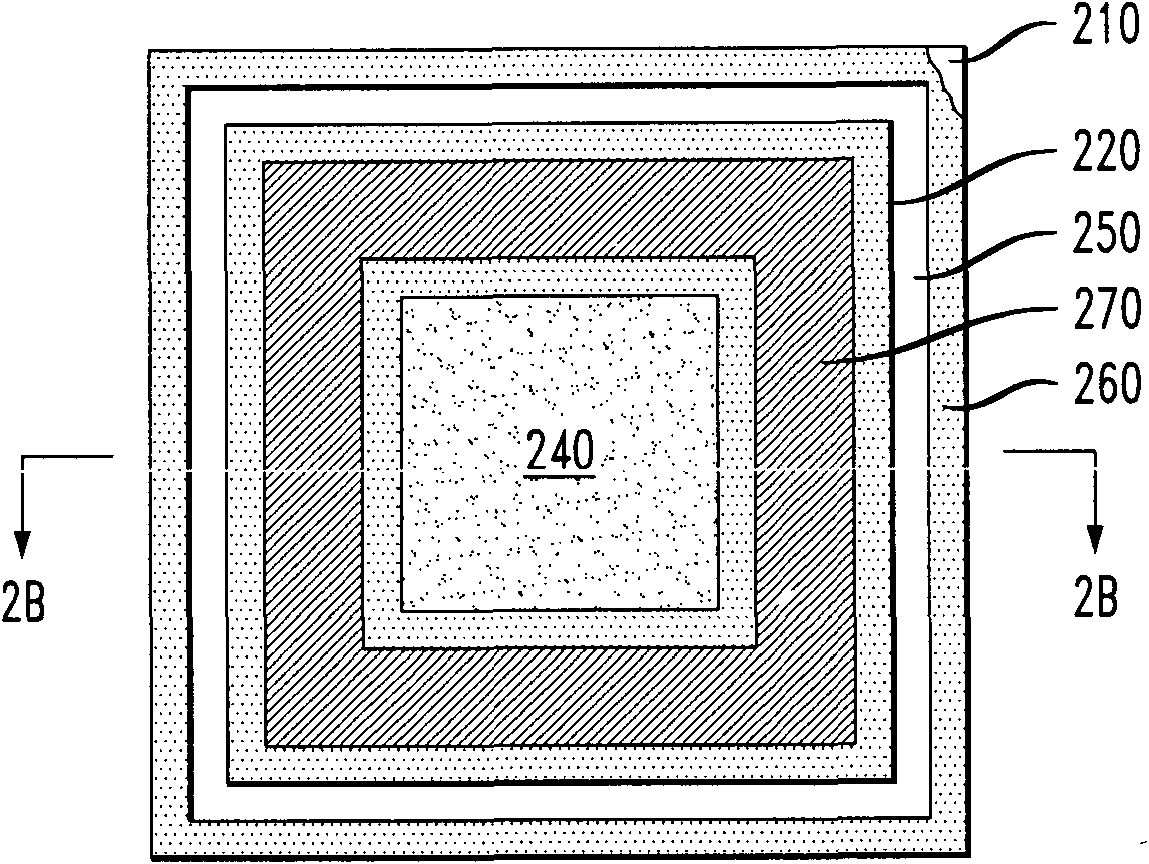

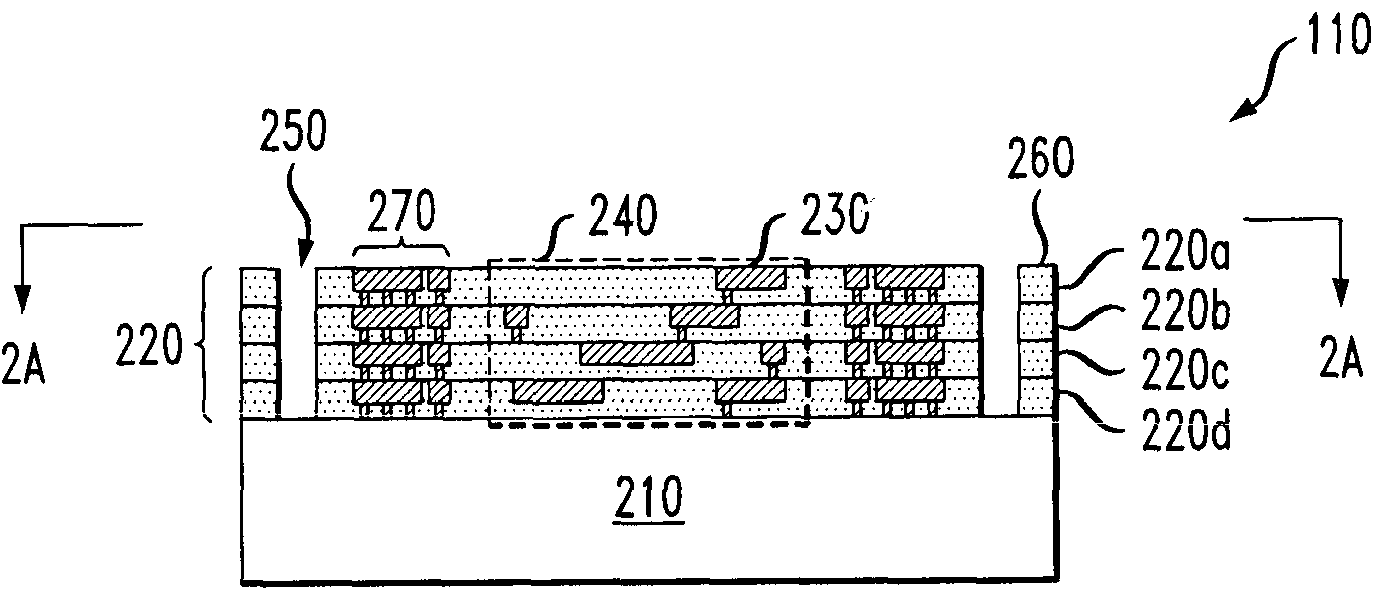

[0016] In some cases, the sealing ring structure cannot prevent the propagation of edge defects. For example, ICs are typically separated in a process called disassembly. One singulation method uses a wafer sawing process (e.g., a rotating grinding wheel) to remove a portion of the substrate (e.g., wafer) and overlying layers in the dicing street between separated integrated circuit dies . The stresses created by the saw blade on the substrate and the dielectric and metal layers formed on the substrate sometimes lead to defects propagating through the seal ring. This defect may result in immediate yield loss, or may result in premature failure of the electronic device.

[0017] Embodiments herein reflect the recognition that propagation of defects initiated during singulation can be prevented by forming a dielectric-free zone between the dicing line and the seal ring. When a defect forms, it can propagate into the dielectric-free region. However, propagation of defects is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com