Cooling water channel structure for motor casing

A technology for cooling water circuit and motor housing, which is applied in cooling/ventilation devices, casings/covers/supports, electrical components, etc., and can solve problems such as burning of stator coils, demagnetization of rotor magnets, affecting the normal operation of motors, etc. , to avoid the leakage of cooling liquid, strengthen the strength of the casing, improve the efficiency and life of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. In this case, the same components are provided with the same reference numerals.

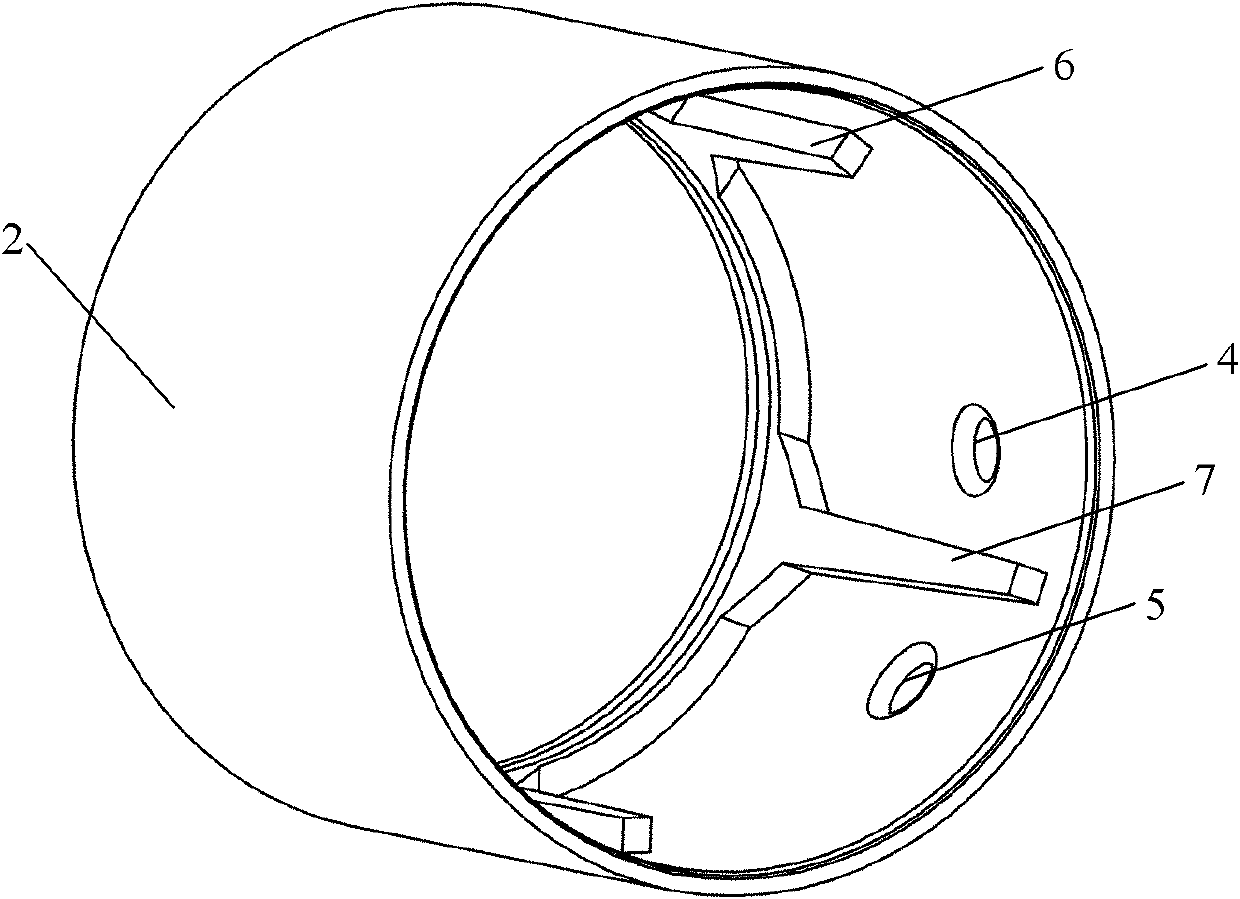

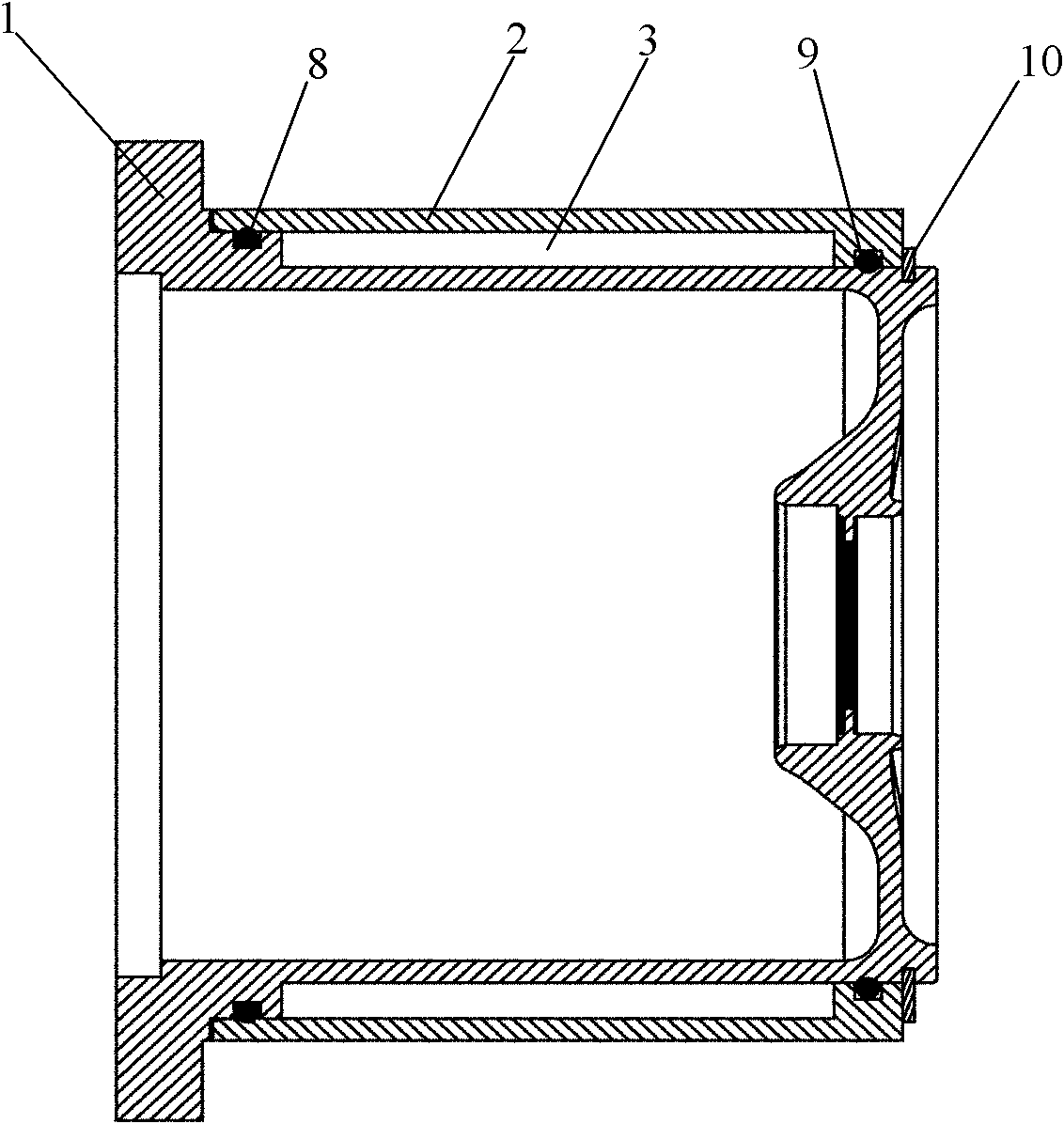

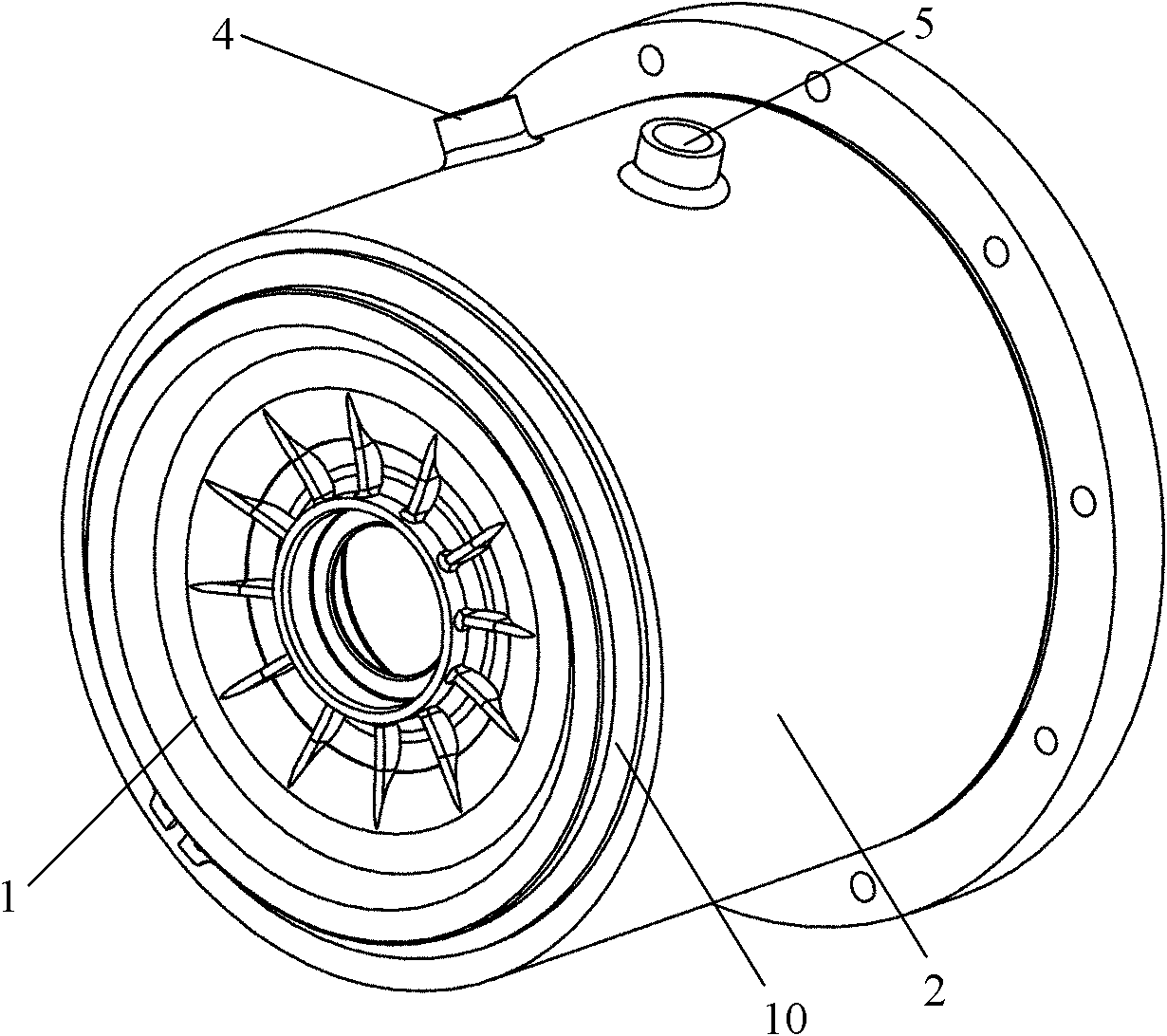

[0029] See Figure 1~5 As shown, the motor casing cooling water circuit structure of the present invention includes a motor inner casing 1 and a motor outer casing 2, and the motor outer casing 2 is sealed and sleeved on the motor inner casing 1 so that the motor inner casing A cooling passage 3 is formed between the body 1 and the motor outer casing 2, and the motor outer casing 2 is provided with a cooling liquid inlet 4 and a cooling liquid outlet 5, and the cooling liquid inlet 4 communicates with the Coolant outlet 5. Therefore, the cooling channel 3 is a one-way cooling channel.

[0030] The cooling channel 3 can have various suitable shapes, and its shape can be formed by setting a reinforcing rib 6. Preferably, the reinforcing rib 6 extends from the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com