Improved printed circuit board (PCB) plating line

An electroplating device and copper plating technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of increasing wastewater treatment volume, unfavorable energy saving and emission reduction, and increasing production costs, so as to reduce wastewater treatment volume and reduce production Cost, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

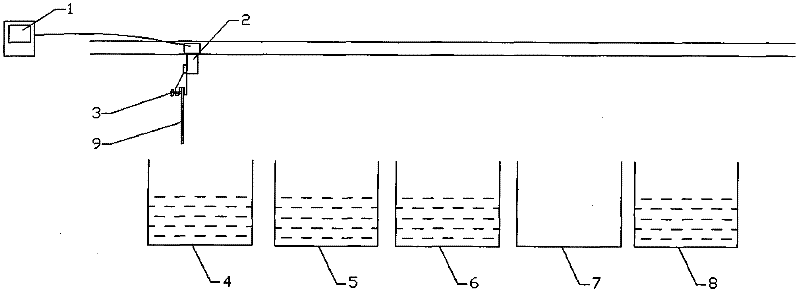

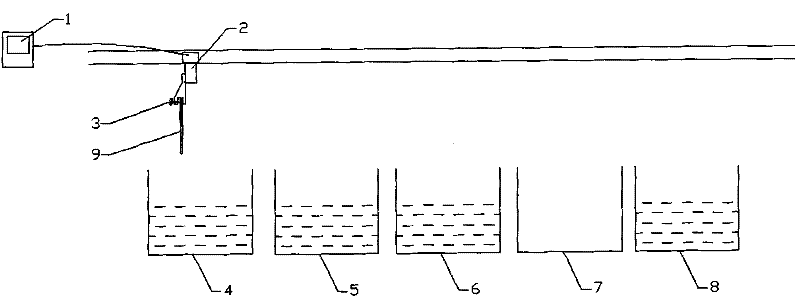

[0010] Such as figure 1 As shown, a kind of PCB electroplating device of the present invention comprises PCB copper plating / etching copper controller 1, hanger 2, chuck 3 on the hanger 2, and copper plating tank 4, the first washing tank 5, Nitric acid tank 6, drip tank 7, second washing tank 8, PCB copper plating / copper corrosion controller 1 is equipped with a corresponding control program to control the crane to drive the hanger 2 to run, and control the dripping of the hanger 2 on the drip tank 7 time.

[0011] work process:

[0012] According to the copper plating process, the PCB9 is clamped on the hanger 2 through the chuck 3 on the workbench, and the control program set in the PCB co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com